Electric wire tube welding operation platform

An operating table and electric wire technology, applied in the field of electrical wire pipe welding operating table, can solve the problems of pipe and junction box positioning, time-consuming and labor-intensive welding, etc., and achieve the effect of enhancing positioning accuracy, facilitating welding, and being easy to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

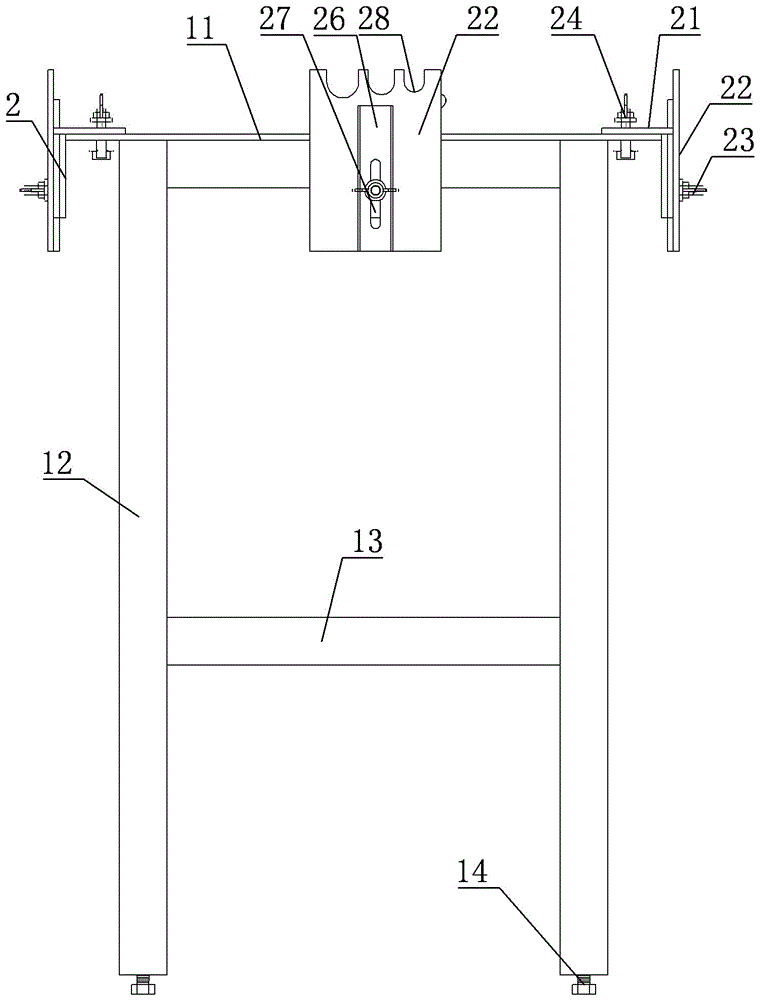

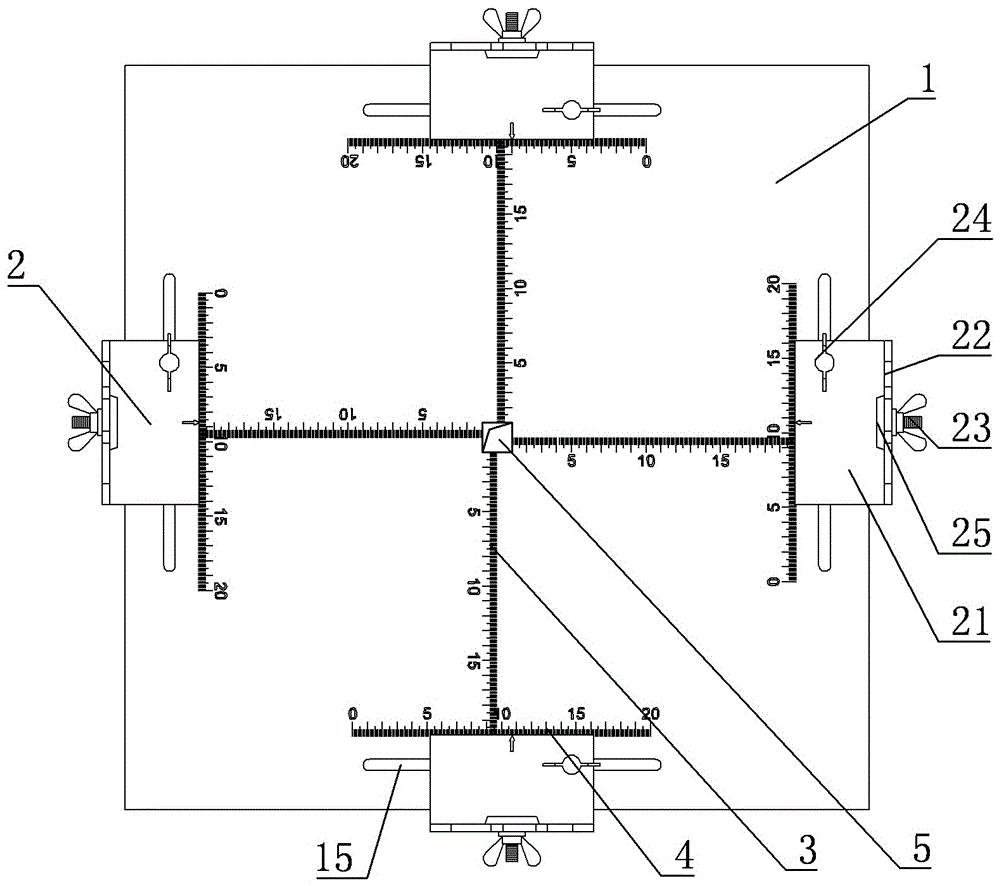

[0024] An electric wire tube welding operation table, its structure is as follows figure 1 and figure 2 As shown, the console body 1 is included, and the console body 1 is made of a 500×500×5mm metal steel plate to make a table 11. The table 11 is provided with a 200mm long horizontal slot 15, and the center of the console body is provided with The reserved hole 5 of 10×10mm, the column 12 and the cross brace 13 adopt 40×40×4mm square steel pipes respectively, the height of the operating platform is 750mm, and the bottom of the column 12 adopts φ6 metal bolts 14 to adjust the stability of the operating platform.

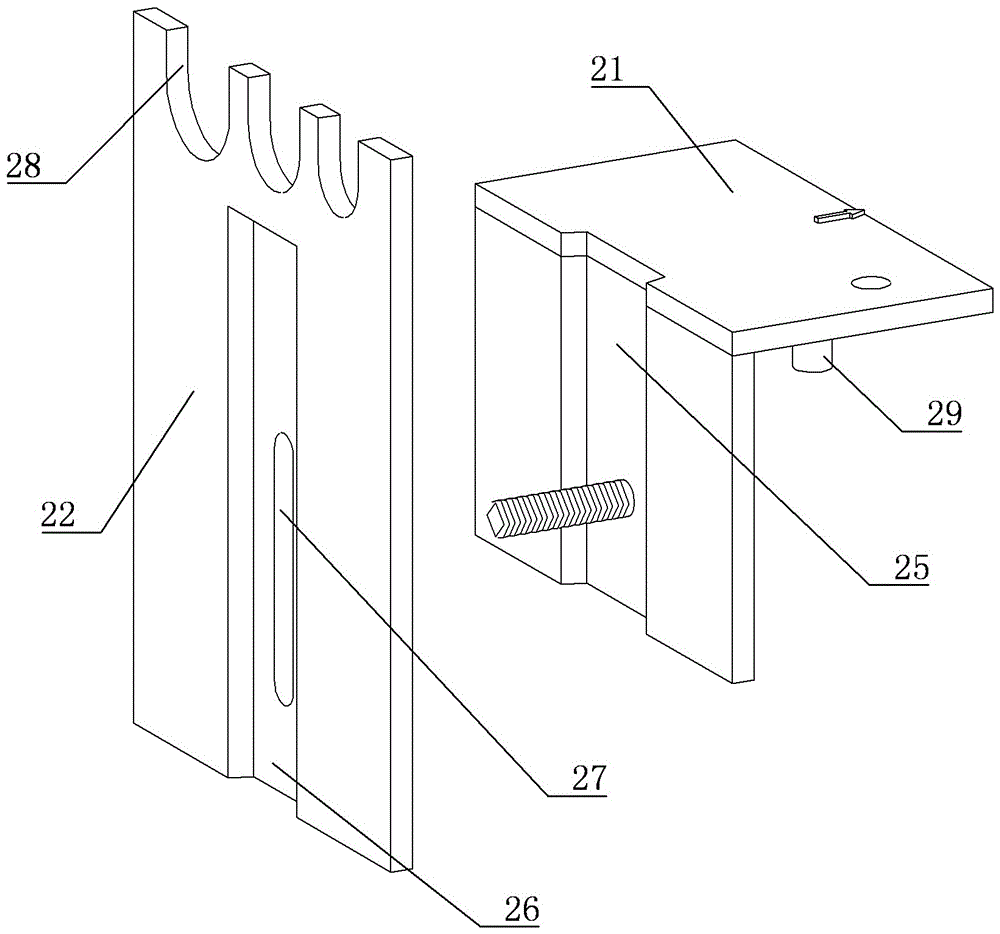

[0025] The four edges of the table top 11 of the operating platform frame body 1 are symmetrically provided with wire pipe fixing regulators 2, and its structure is as follows: image 3 As shown, the wire pipe fixing regulator 2 includes a horizontal reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com