Stepless speed change type vertical driller

A vertical drilling machine, stepless speed change technology, applied in the direction of boring machine/drilling machine parts, boring/drilling, drilling/drilling equipment, etc., can solve the problem of large size of vertical drilling machine, interrupted drill bit, inconvenient placement and other problems, to achieve the effect of stepless speed regulation, reduce the meshing coefficient, and facilitate the disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

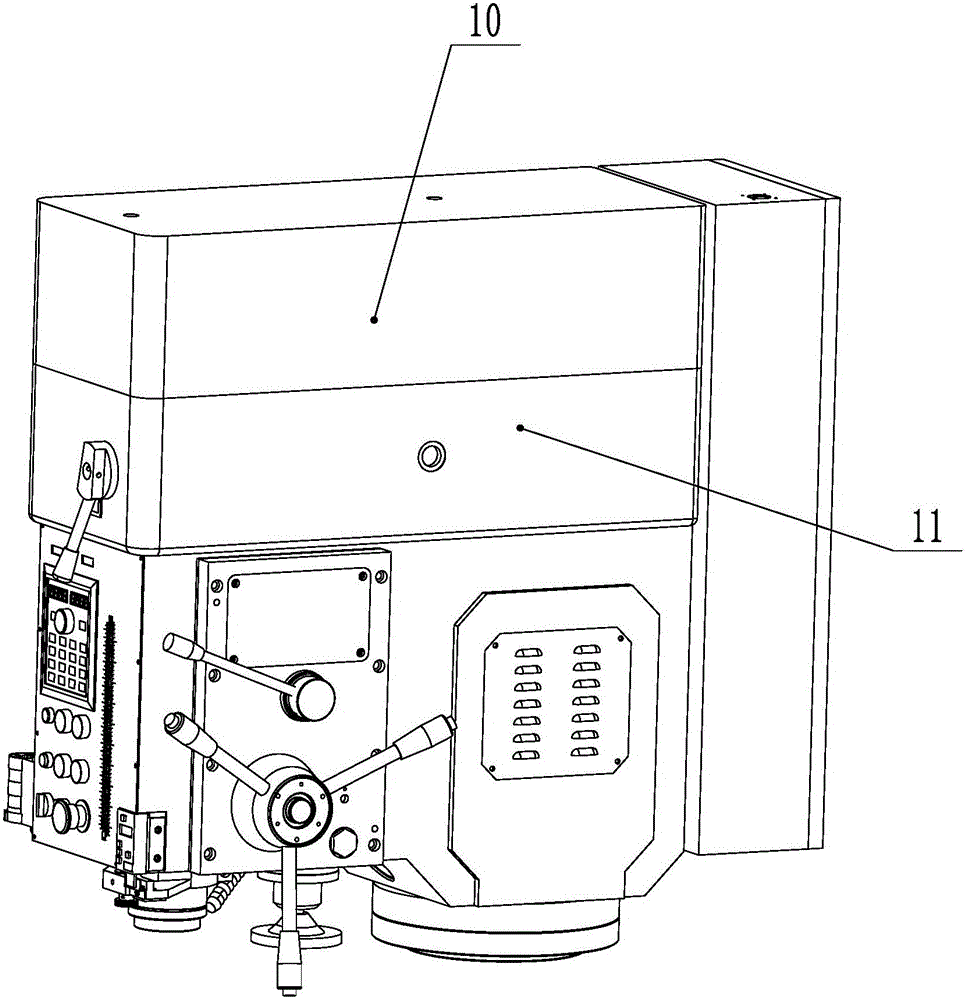

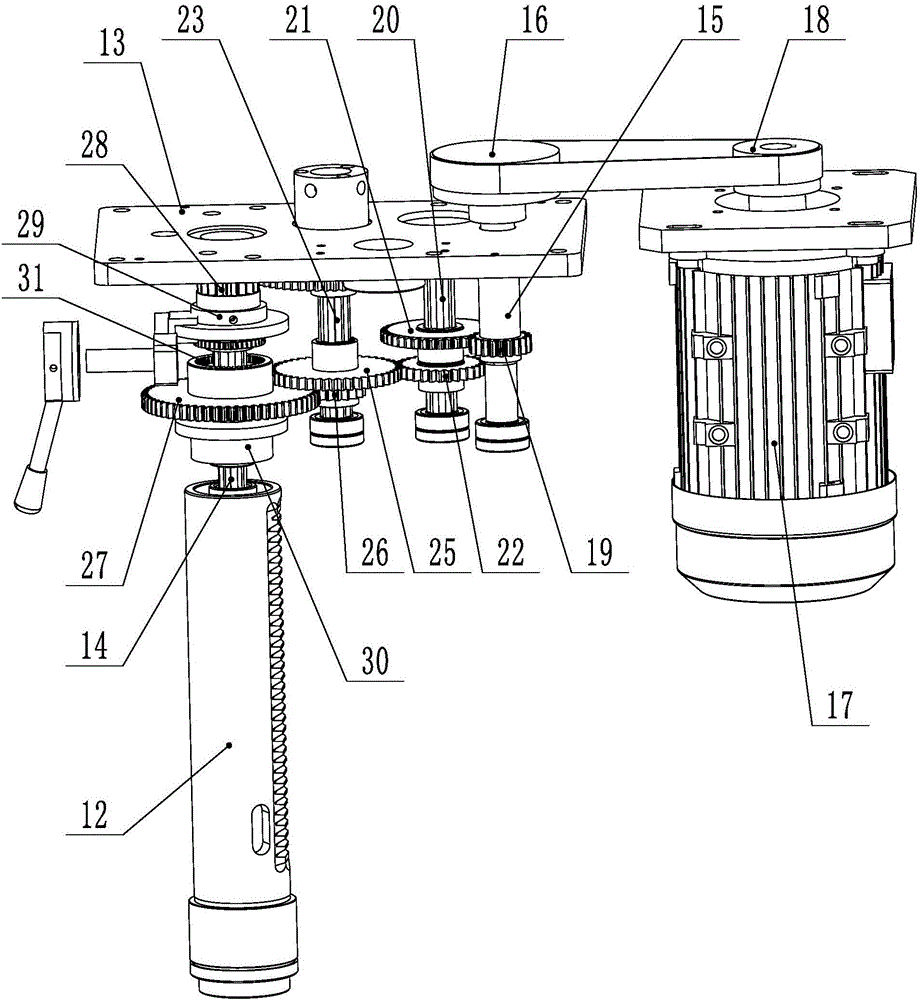

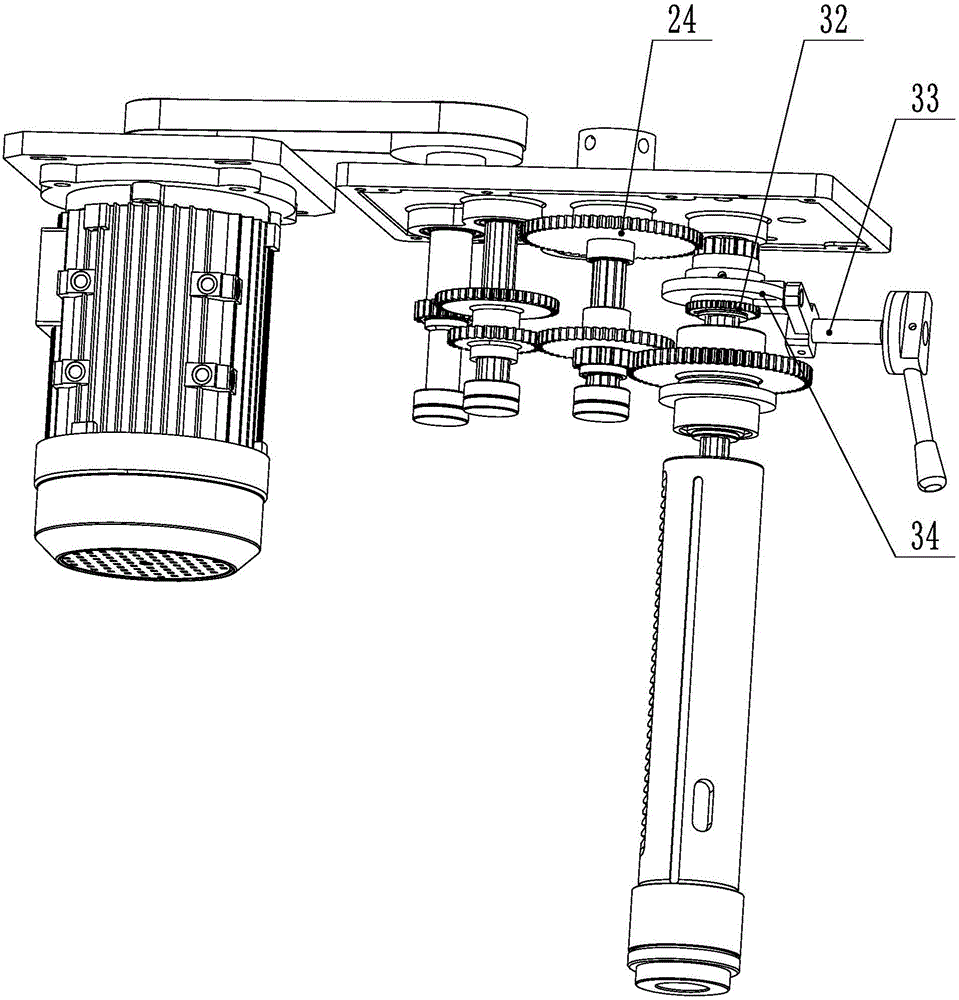

[0025] Reference Figure 1~3 , Is a continuously variable vertical drilling machine disclosed in the present invention. The casing is divided into upper and lower casings 10 and 11 by partitions. The lower casing 11 is provided with a sleeve 12 extending out of the lower casing 11 , The secondary shaft 14 is installed on the partition 13 in the lower box 11, the sleeve 12 is sleeved on the secondary shaft 14 and can slide axially along the secondary shaft 14, the partition on the side of the secondary shaft 14 in the lower box 11 13 is provided with a main shaft 15 penetrating through the partition 13 and the main shaft 15 penetrates the partition 13 and extends into the upper box body 10. The main shaft 15 in the upper box body 10 is equipped with a secondary transmission wheel 16, and the upper box body 10 or / and the lower box A permanent magnet motor 17 is installed on one side of the body 11, and a main transmission wheel 18 that drives the auxiliary transmission wheel 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com