A non-emission presulfidation process and device for sulfur recovery hydrogenation catalyst

A hydrogenation catalyst and sulfur recovery technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of unavailability, excessive discharge of equipment, and large amount of pre-sulfurized residual gas. The effect of strong operability, safe and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

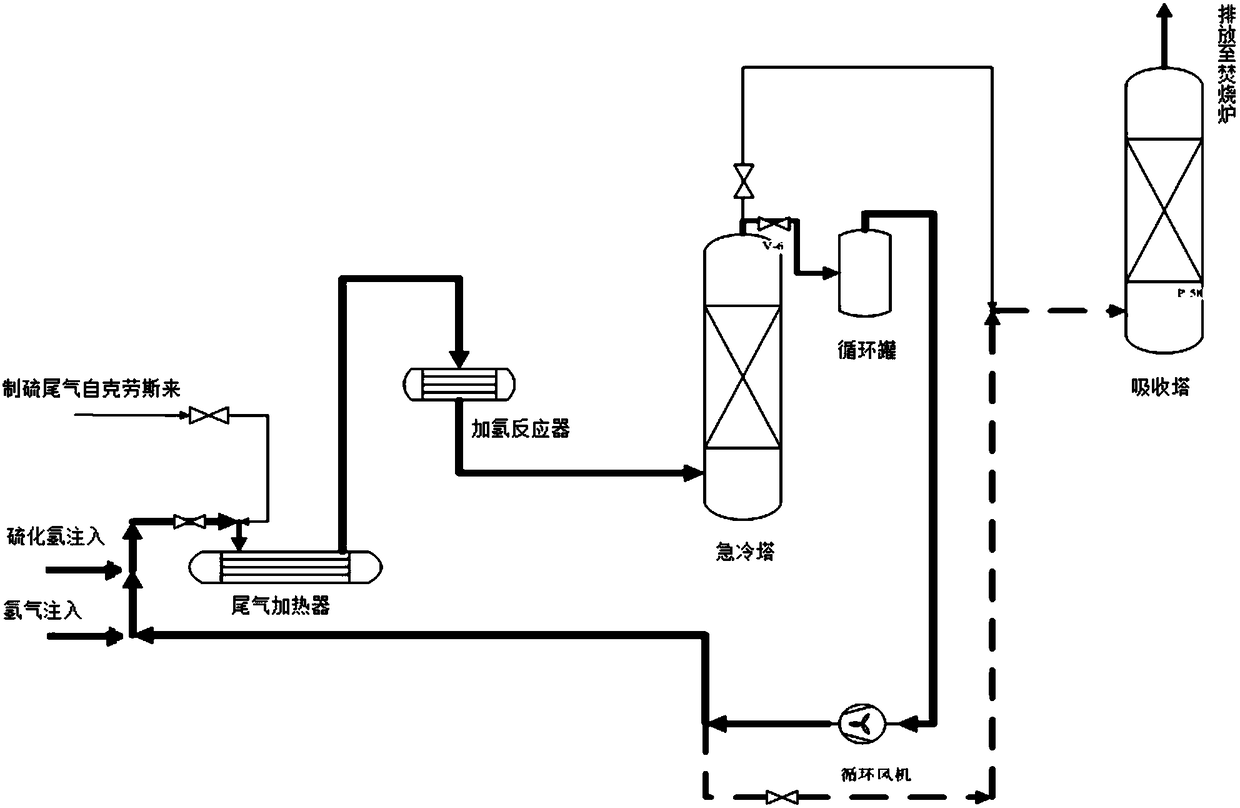

[0028] Such as figure 1 Shown, a kind of sulfur recovery hydrogenation catalyst does not discharge the pre-sulfurization process, and it comprises the following steps:

[0029] ① Establish a pre-vulcanization process and fill it with pre-vulcanization circulating gas nitrogen, and start the circulating fan when the system pressure rises to 0.01Mpa;

[0030] ②Enable the tail gas heater to heat the circulating gas to gradually preheat the hydrogenation catalyst to 200°C. The pre-sulfurized circulating gas is compressed by the circulating fan and mixed with hydrogen sulfide and hydrogen to form hydrogen sulfide-rich pre-sulfurized gas and enter the tail gas heater;

[0031] ③The hydrogen sulfide-enriched presulfurized gas after heating enters the hydrogenation reactor to presulfide the hydrogenation catalyst, and the molar concentration of hydrogen sulfide in the presulfurized circulating gas entering the hydrogenation reactor reaches 1-2%, and the molar concentration of hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com