Full-automatic dish stir-frying machine

A cooking machine, a fully automatic technology, applied in cooking utensils, household appliances, applications, etc., can solve the problems of inability to continuously stir-fry dishes, the number of finished dishes is large, and easy to get raw or burnt, so as to improve social and economic benefits. Benefit, high degree of automation, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

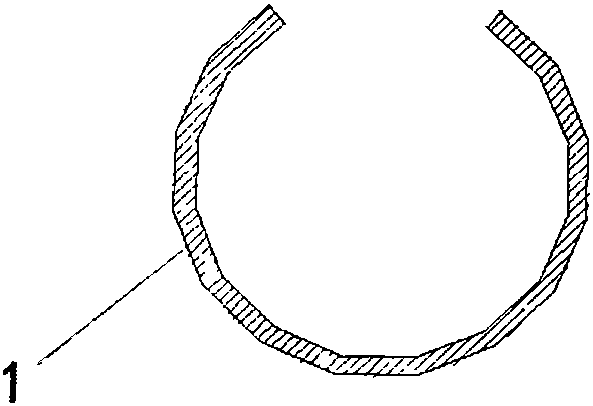

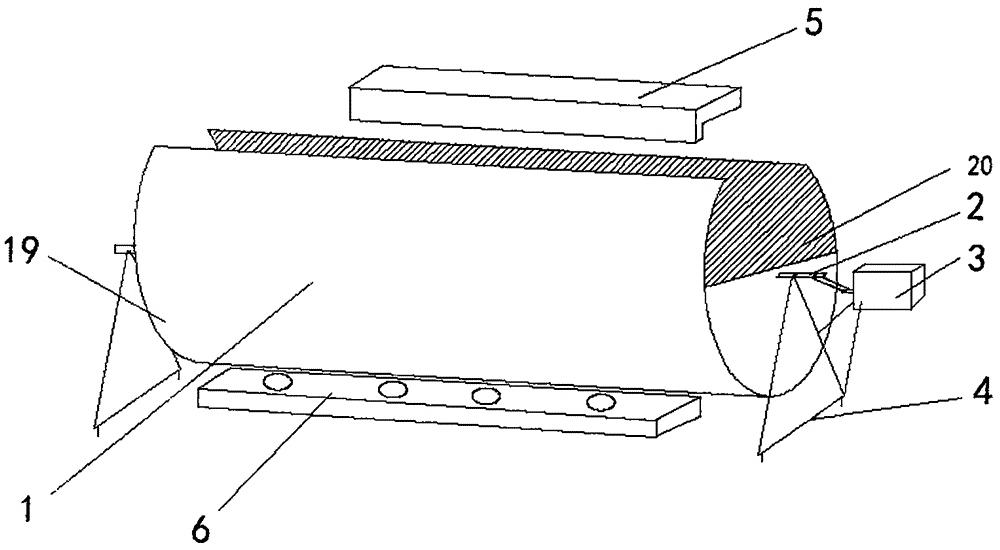

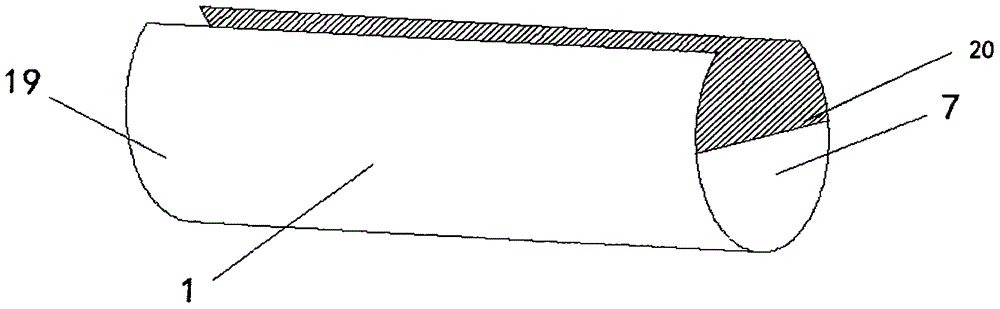

[0046] exist figure 1 , figure 2 , image 3 In the shown embodiment, the cylindrical frying pan (1) (1) is a trough-shaped container with a circular upper opening in cross section, and the position of the feed port is at the upper opening of the cylindrical frying pan (1) (1). Place, do not install pot cover, feed end (20) end part is closed.

[0047] exist Figure 4 In the shown embodiment, the cylindrical frying pan (2) (8) is a cylindrical container with a circular cross section.

[0048] exist Figure 5 , Image 6 In the shown embodiment, the cylindrical frying pan (3) (9) is a trough-shaped container with a polygonal cylindrical container with an upper opening.

[0049] exist Figure 7 , Figure 18 In the shown embodiment, what the rotation or swing mechanism (2) (14) adopted is a suspension rod or a suspension chain or a suspension rope, and the way that the cylindrical frying pan (3) (9) is installed on the reciprocating device is a waist type Hole fastening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com