Inserted-bar type synchronous dry-out method for porphyra haitanensis

A technology of alga laver and inserting rods, which is applied in the field of seaweed aquaculture, can solve the problems of laver aging, diatom attachment, and poor quality, and achieve the effects of synchronous growth, consistent materials, and improved yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for synchronously drying altar laver, comprising the following steps:

[0040] (1) Construct a checkerboard-shaped rod frame:

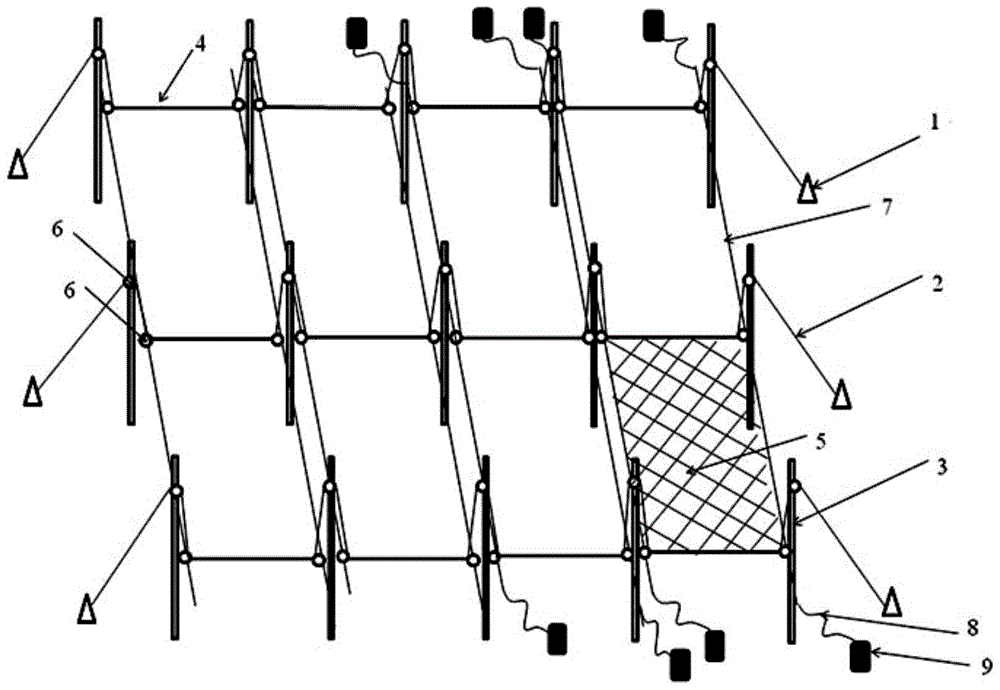

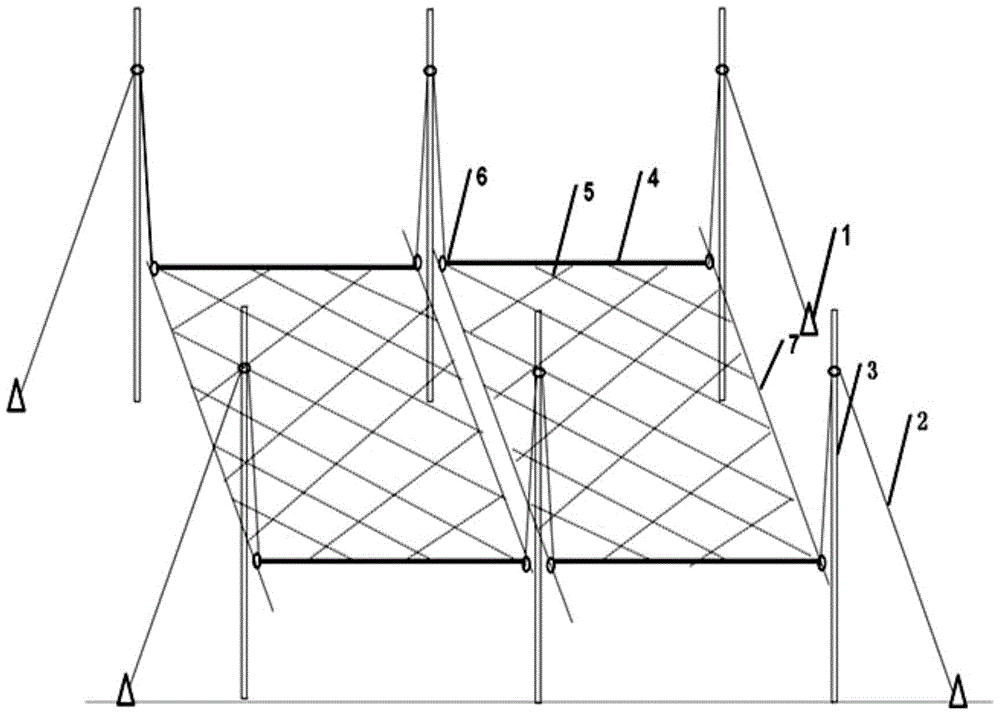

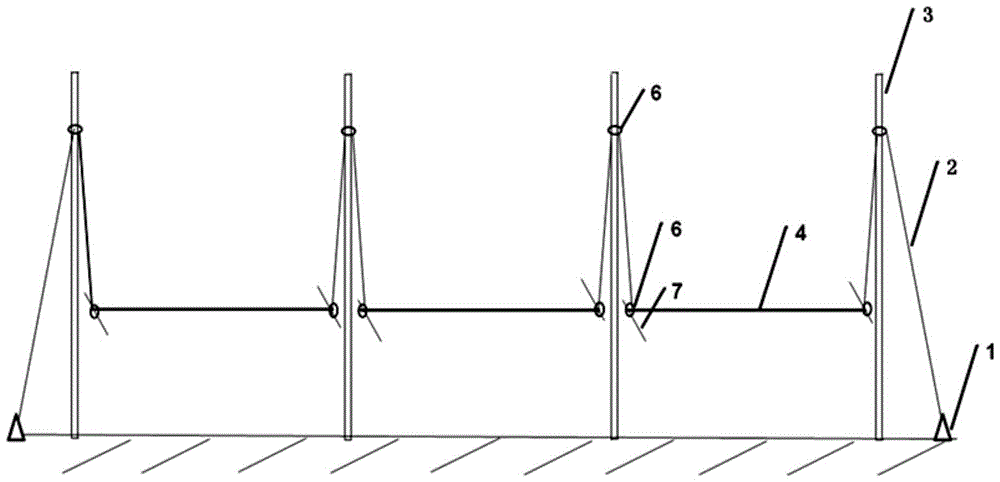

[0041]Select the cultivation tidal level suitable for Porphyra laver, and arrange the inserting rods 3 in rows from the high tide level to the low tide level, consistent with the direction of seawater flow; Looking down, it forms a checkerboard shape; on the outer beach surface of the outermost insertion rods of the rows of insertion rods, a plurality of adjustment piles 1 are set up, and the adjustment piles correspond to the insertion rods one by one;

[0042] A quarter of the upper part of the insertion rod is fixed with a suspension ring 8, which is a movable pulley;

[0043] The distance between the inserted rods in a row is 2.8 to 3.3 times the length of the struts;

[0044] The distance between the inserted rods in a row is 1.1 to 1.3 times the length of the struts;

[0045] There are 20 inserting rods in each column, 10 in e...

Embodiment 2

[0062] A method for synchronously drying altar laver, comprising the following steps:

[0063] (1) Construct a checkerboard-shaped rod frame:

[0064] Select the cultivation tidal level suitable for Porphyra laver, and arrange the inserting rods 3 in rows from the high tide level to the low tide level, consistent with the direction of seawater flow; Looking down, it forms a checkerboard shape; on the outer beach surface of the outermost insertion rods of the rows of insertion rods, a plurality of adjustment piles 1 are set up, and the adjustment piles correspond to the insertion rods one by one;

[0065] A quarter of the upper part of the insertion rod is fixed with a suspension ring 8, which is a movable pulley;

[0066] The distance between the inserted rods in a row is 2.8 to 3.3 times the length of the struts;

[0067] The distance between the inserted rods in a row is 1.1 to 1.3 times the length of the struts;

[0068] There are 18 inserting rods in each column, 8 in e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com