Welding safety monitoring system based on multi-sensor coordination

A safety monitoring and multi-sensor technology, applied in the field of monitoring systems, can solve problems affecting physical health and work efficiency, damage to peripheral arc radiation, skin tissue damage, etc., and achieve low cost, high cost performance, and strong functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

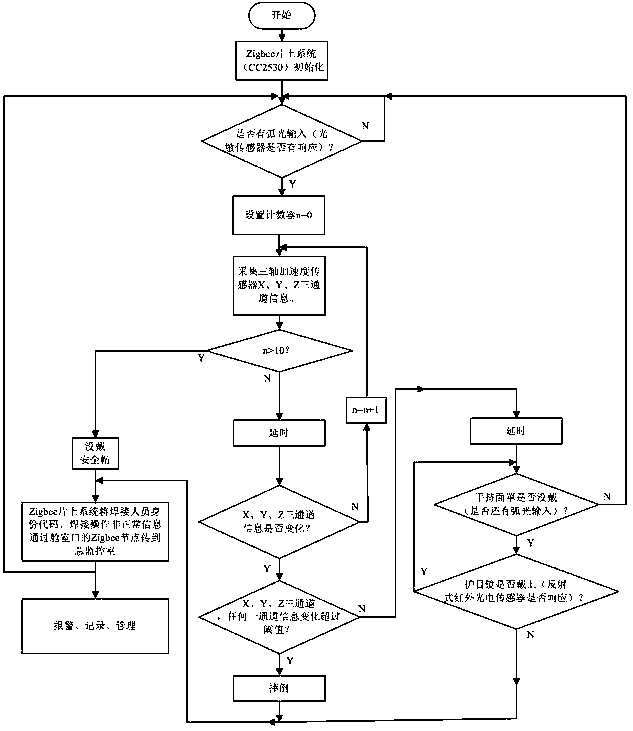

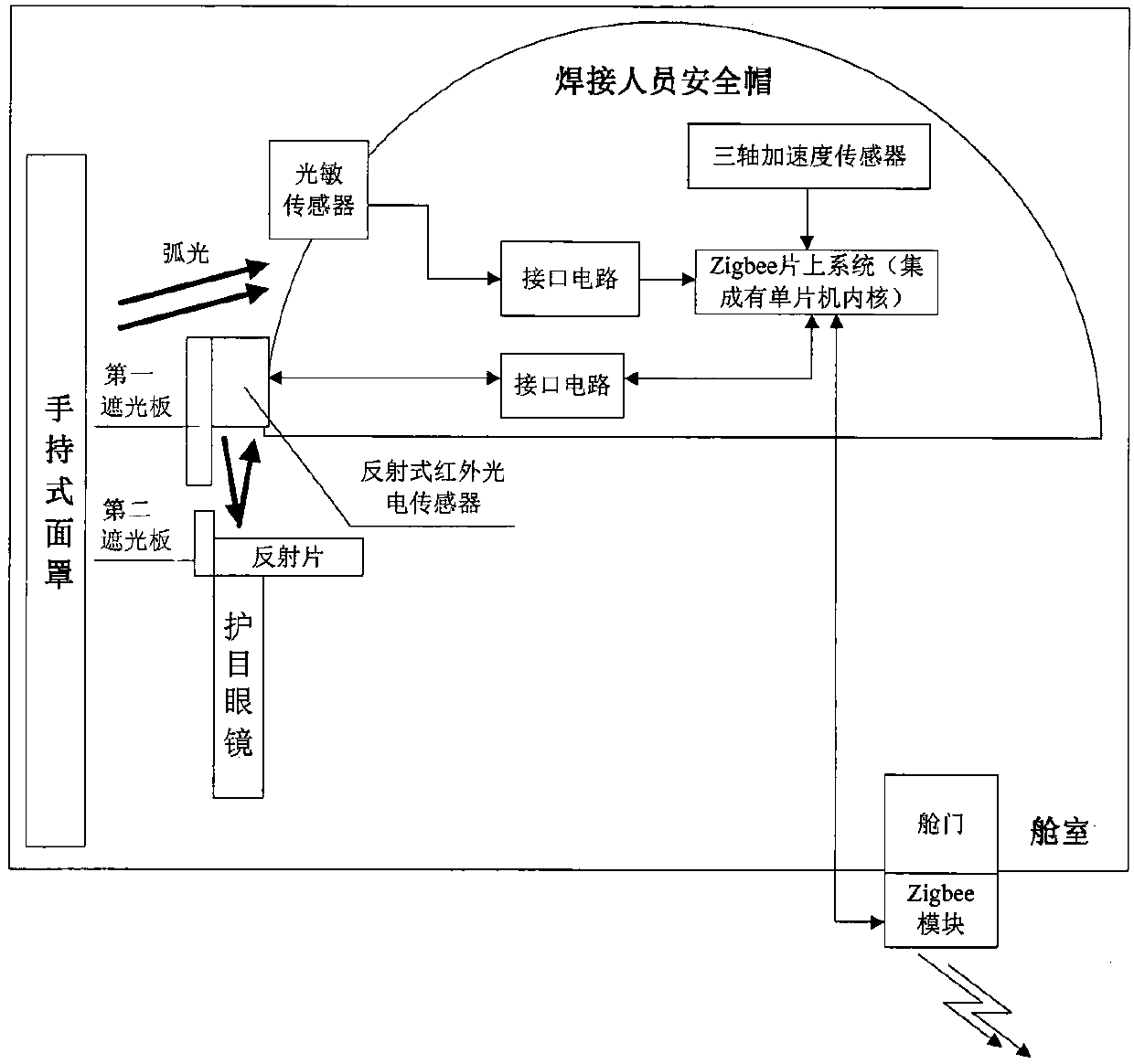

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] A remote monitoring and alarm system for ship welding personnel based on multi-sensor information fusion, which mainly consists of the following parts (refer to figure 1): Welding helmet, Zgibee system on chip (integrated with MCU core), photosensitive sensor and photosensitive sensor interface circuit, reflective infrared photoelectric sensor and reflective infrared photoelectric sensor interface circuit, three-axis acceleration sensor, reflector, first shading board, second visor, goggles, hand-held mask, Zigbee module. Zigbee system-on-chip (integrated with a single-chip microcomputer core), photosensitive sensor and photosensitive sensor interface circuit, reflective infrared photoelectric sensor and reflective infrared photoelectric sensor interface circuit, the first light shield, and three-axis acceleration sensor are all installed on the welder's helmet....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com