Sandy deposited particle distinguishing method

A technology for sedimentary particles and sandy quality, applied in the field of sedimentology, it can solve the problems of poor reliability, narrow application range, and lack of quantitative differentiation of sedimentary environments, and achieves the effects of high accuracy, accurate judgment results, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

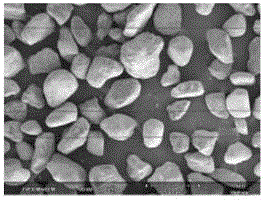

[0043] Example: such as Figure 1 to Figure 6 Shown, the present invention comprises the following steps:

[0044] Step 1. Sample collection and processing:

[0045] 1) Sample cleaning: first take about 500g of loose samples collected from the field (adjustable according to the needs of different researches), put them into a 1000ml beaker, soak and rinse with tap water, and remove the mud;

[0046] 2), sample drying: dry the remaining debris particles and pass through a 60-80 mesh sieve to obtain particles between 60-80 mesh;

[0047] 3) Pick out quartz particles: select colorless, transparent and greasy quartz particles through binoculars, mix them with 20% hydrochloric acid, soak them for 8 hours to remove carbonic acid, and then clean these quartz particles with tap water , then dry.

[0048] 4) Gold plating: Paste the last picked quartz particles on the sample stage with conductive glue, put them into the gold plating device, perform gold plating for about 5 minutes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com