Test device and test method for simulating anti-floating anchor-concrete slab composite structure

A technology of concrete slab and test device, which is applied in the test of basic structure, measuring device, basic structure engineering, etc., can solve the problems of waste of groundwater resources, surrounding surface, uneven settlement of underground pipelines of buildings, multiple engineering accidents, etc. effect made

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with embodiment.

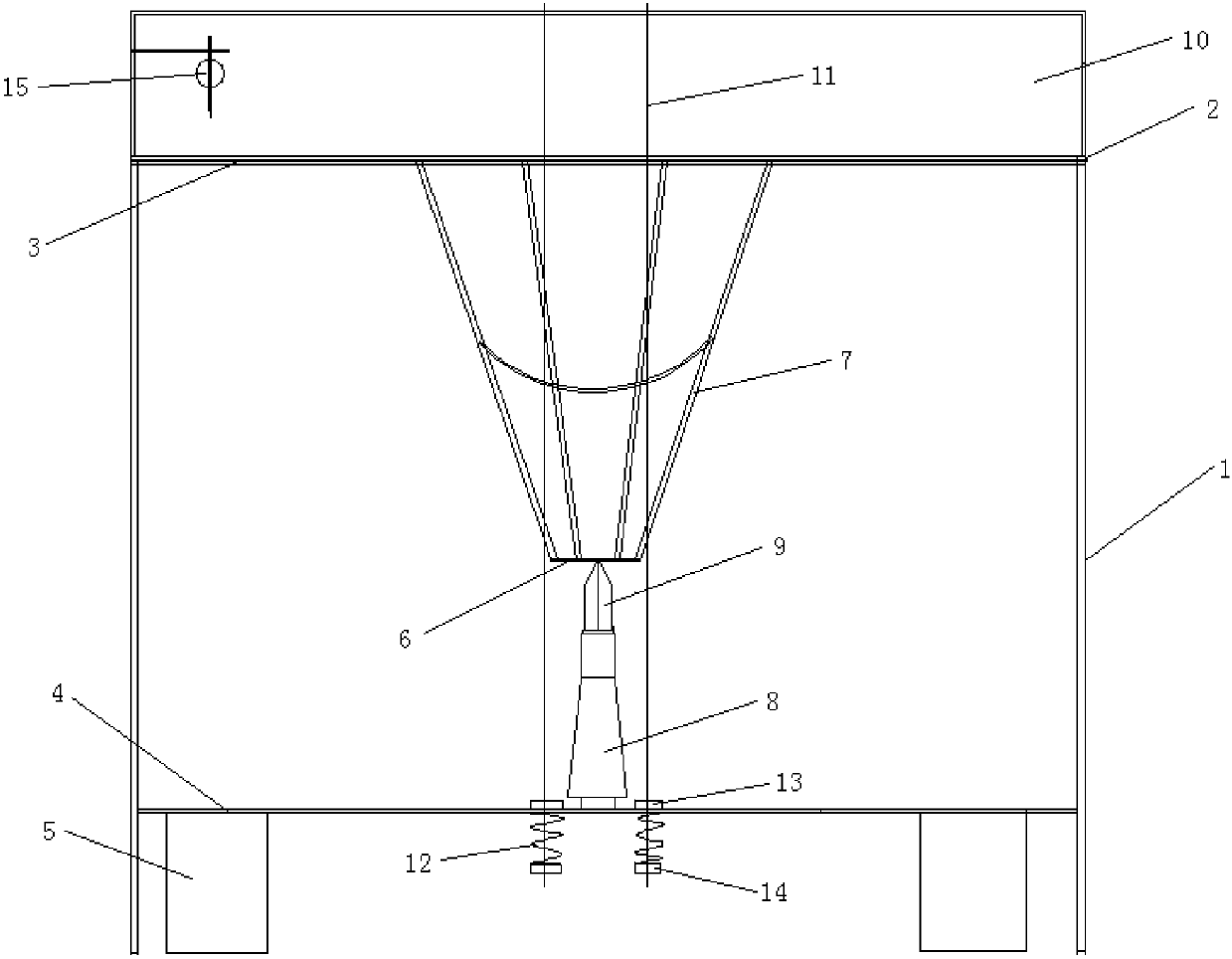

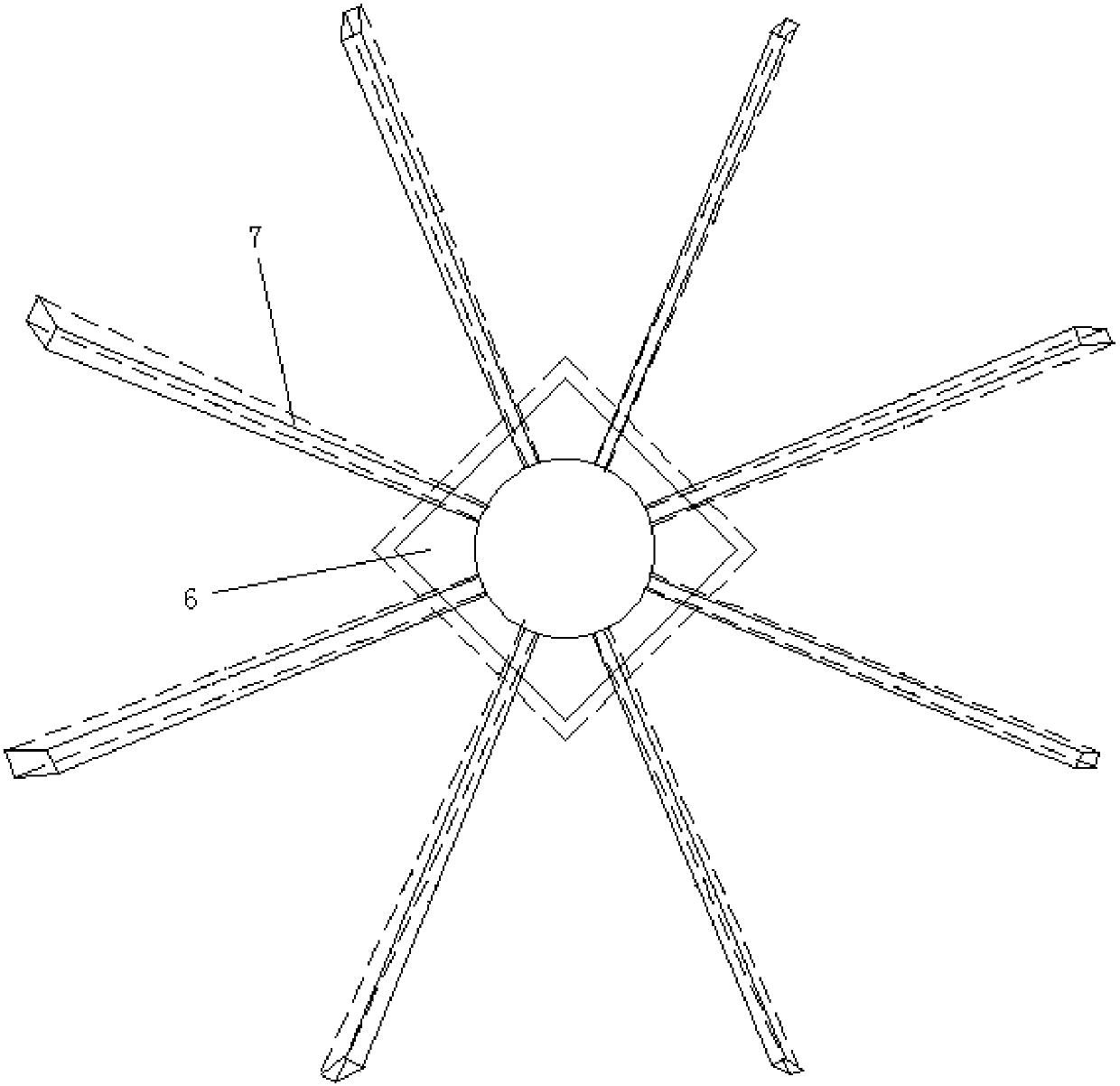

[0053] according to Figure 1 ~ Figure 2 As shown, a test device for simulating the anti-floating anchor rod-concrete slab composite structure includes a load-bearing device, and the load-bearing device is provided with a force transmission device, a force application device and a test device.

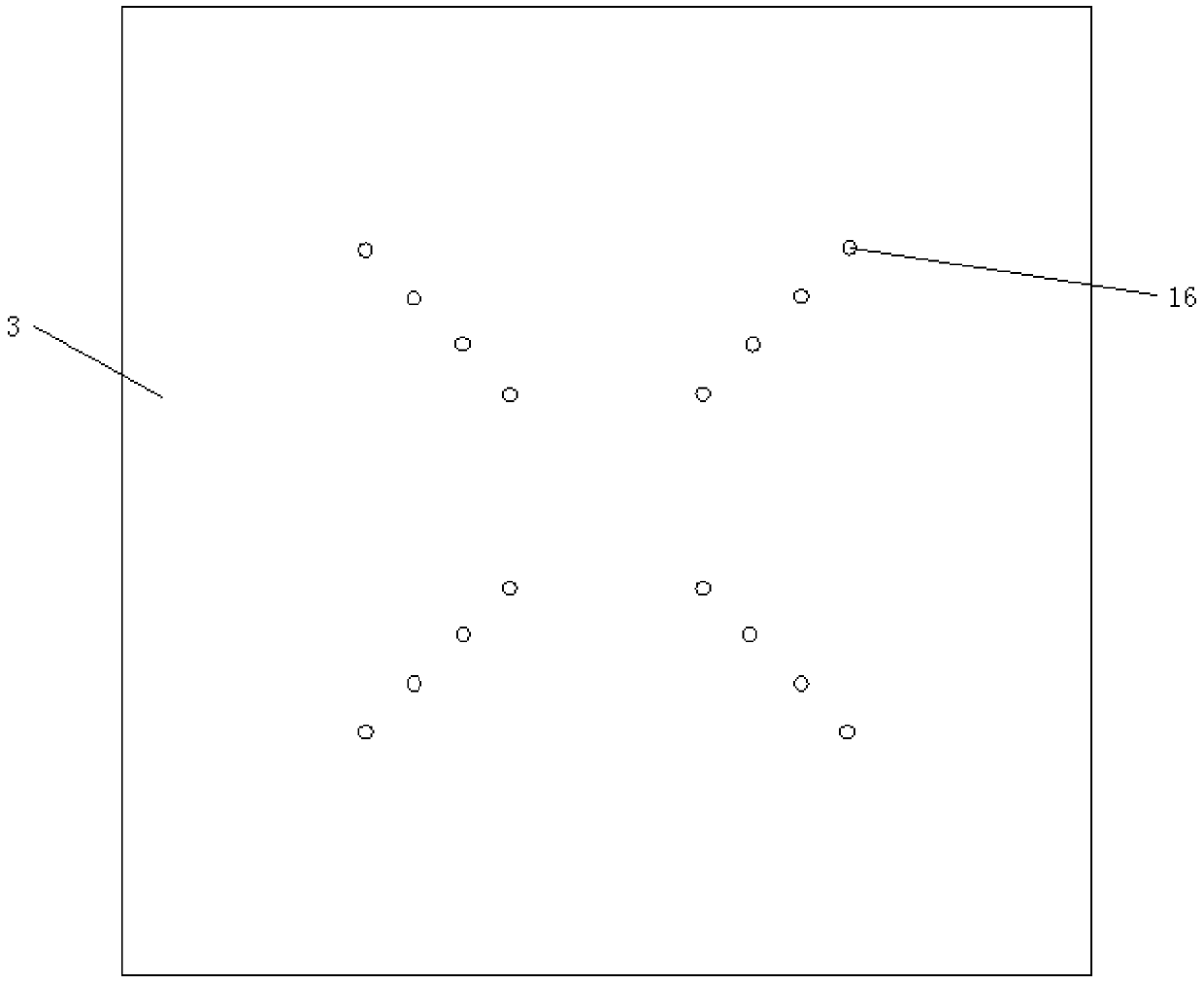

[0054] The load-bearing device includes a skeleton 1, the skeleton 1 is composed of four equal-length pillars welded, four steel beams 2 are arranged on the upper part of the pillars, and the upper support plate 3 is placed on the steel beam 2, and the upper support plate 3 can be opposite to each other. The upper end of the frame 1 moves upward, the lower end of the frame 1 is provided with a lower support plate 4, and the lower part of the lower support plate 4 is provided with a cushion block 5 to support the lower support plate 4, and the lower support plate 4 can be placed insi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com