Cement rotary kiln intelligent air cooling device

A technology of cement rotary kiln and air cooling device, which is applied in furnace cooling, rotary drum furnace, furnace, etc., which can solve the problems of personnel safety hazards, complex site environment, and heavy fan weight, and achieve reduced safety hazards, good reliability, and The effect of multiple wind outlet angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

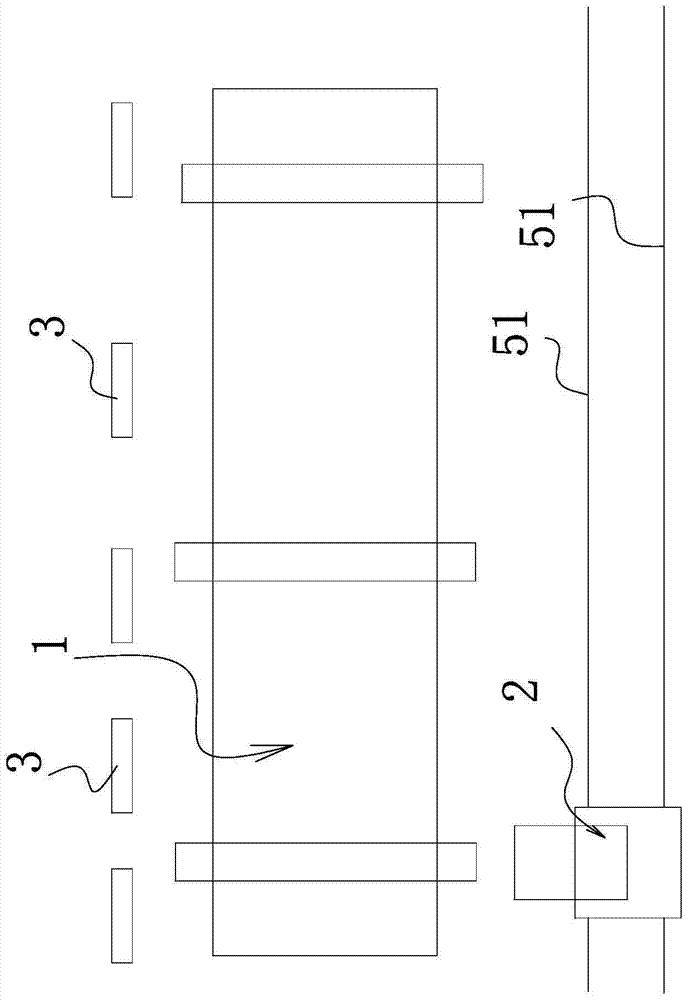

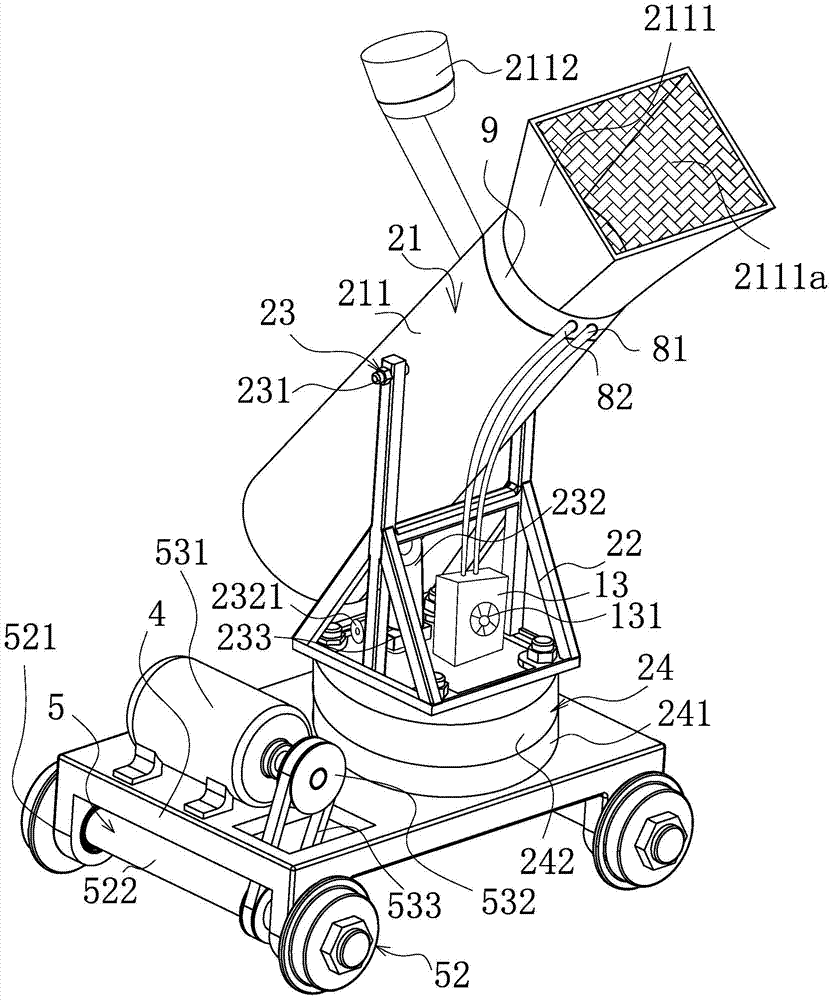

[0019] Such as Figure 1-4 As shown, the cement rotary kiln intelligent air-cooling device is characterized in that it includes an air-cooling mechanism 2 arranged on one side of the rotary kiln shell 1 and a number of temperature sensors 3, the air-cooling mechanism 2 is arranged on the base 4, and on the base 4 is provided with a moving assembly 5 capable of driving the base 4 to reciprocate axially along the central axis of the rotary kiln shell 1, the temperature sensor 3 and the moving assembly 5 are connected to the control system 6, and the control system 6 has wired and / or wireless A control panel 7 is connected. The use of the device can effectively reduce the temperature of the rotary kiln shell 1, and reduce the occurrence of potential safety hazards, without the need for overriding personnel to perform cooling operations now.

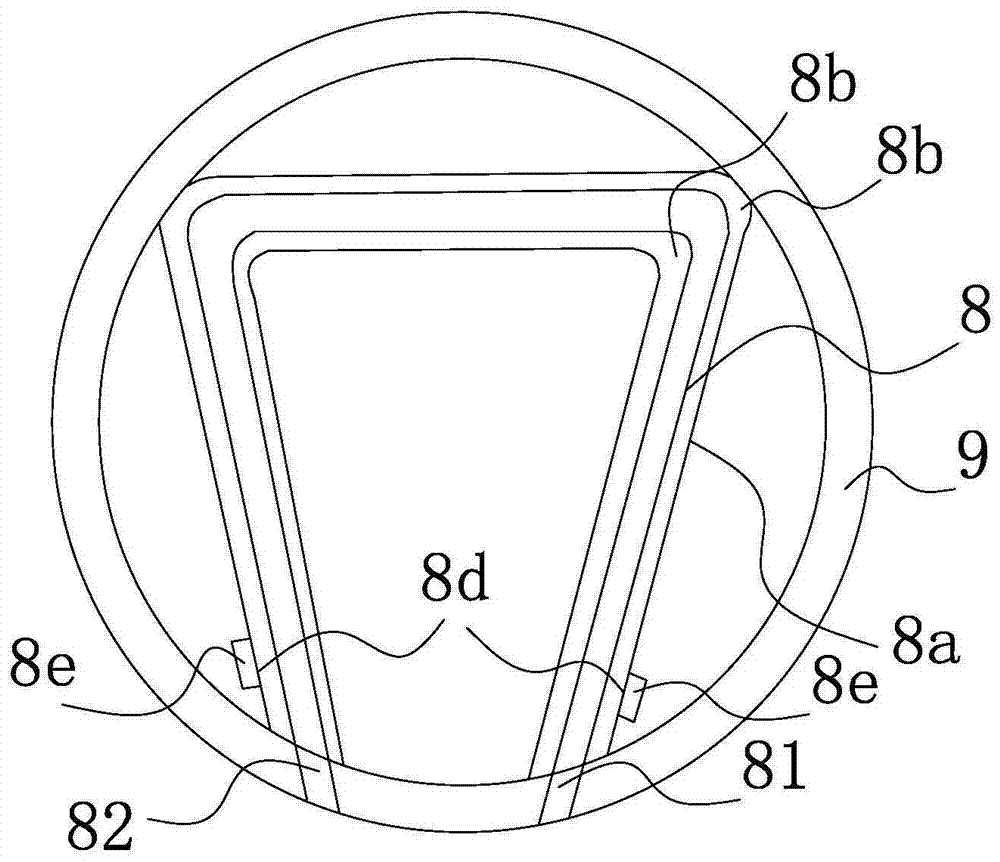

[0020] The air-cooling mechanism 2 includes a fan 21 arranged on the base 4, the fan 21 is connected to the base 4 through a frame 22, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com