High-temperature air and high-temperature low-oxygen smoke mixed combustion-supporting type full-automatic control ceramic kiln

A high-temperature, low-oxygen, and flue gas mixing technology is applied in the direction of combustion control, combustion method, and fuel supply adjustment. It can solve problems such as inability to automatically adjust the system, cumbersome assembly, and affect combustion efficiency, so as to achieve effective use of energy. Simple and compact structure, easy to assemble and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

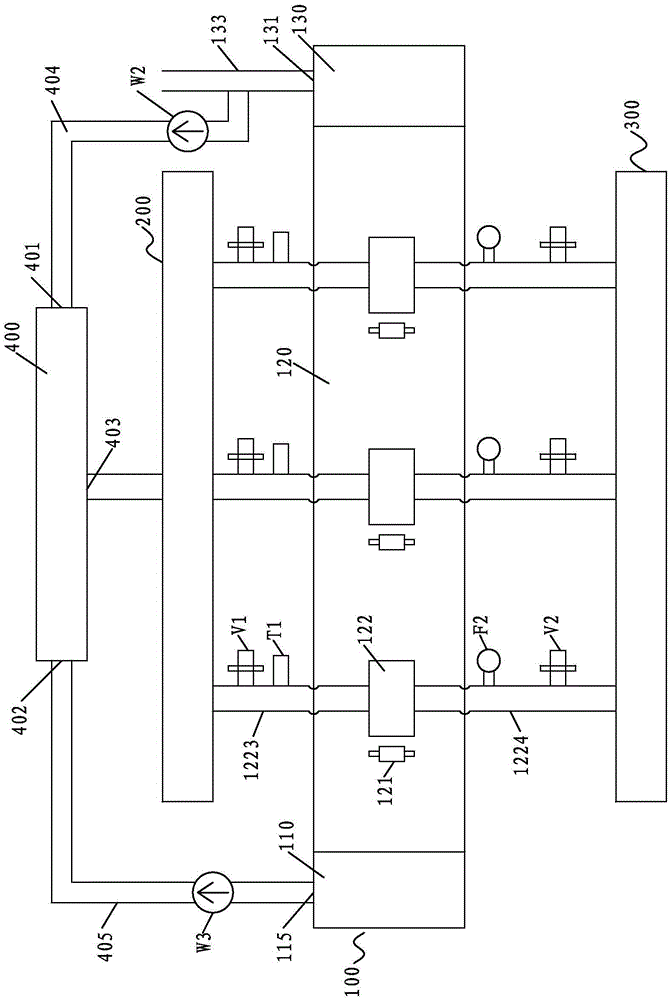

[0032] Please refer to figure 1 According to a non-limiting embodiment of the present invention, the high-temperature air plus high-temperature low-oxygen flue gas mixed combustion-supporting automatic control ceramic kiln of the present invention includes a kiln body 100 , a gas-supporting main pipe 200 , and a gas main pipe 300 .

[0033] The interior of the kiln body 100 is provided with a furnace (not labeled), and the kiln body 100 is divided into a cooling section 110, a combustion section 120 and a preheating section 130 along the longitudinal direction. Control partition (unnumbered).

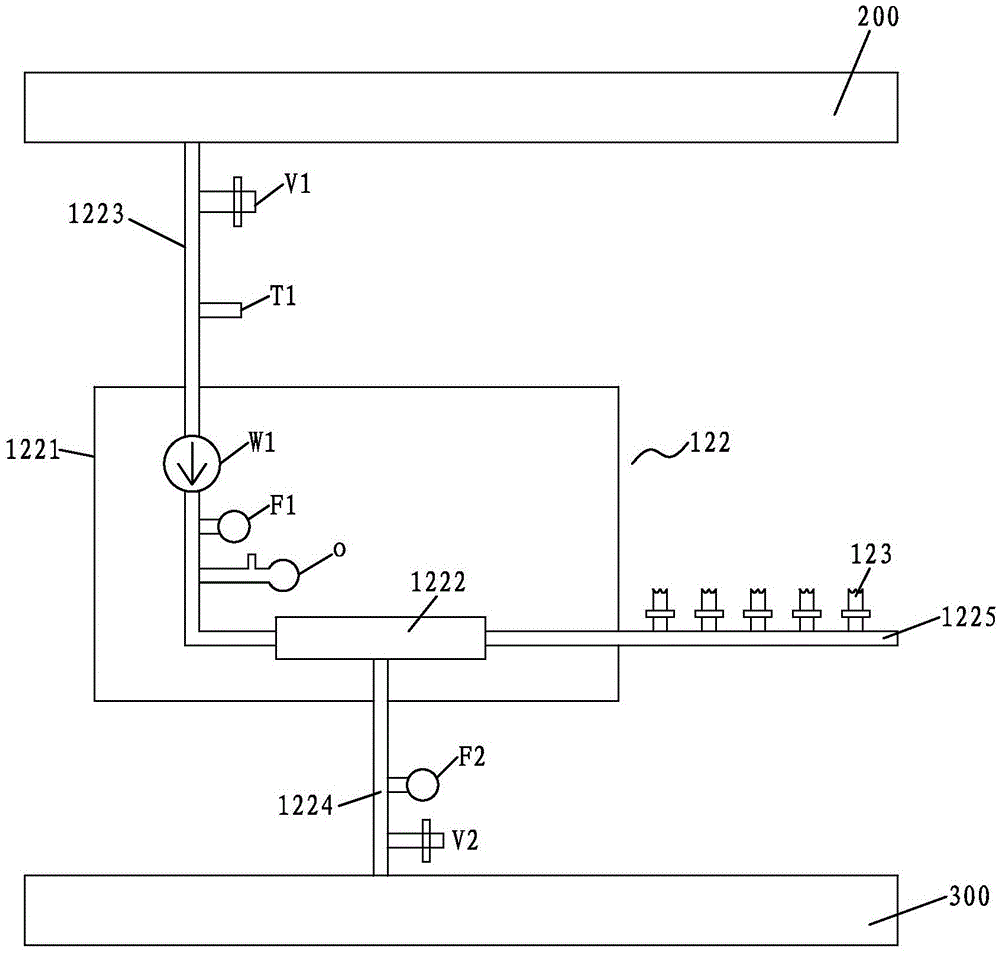

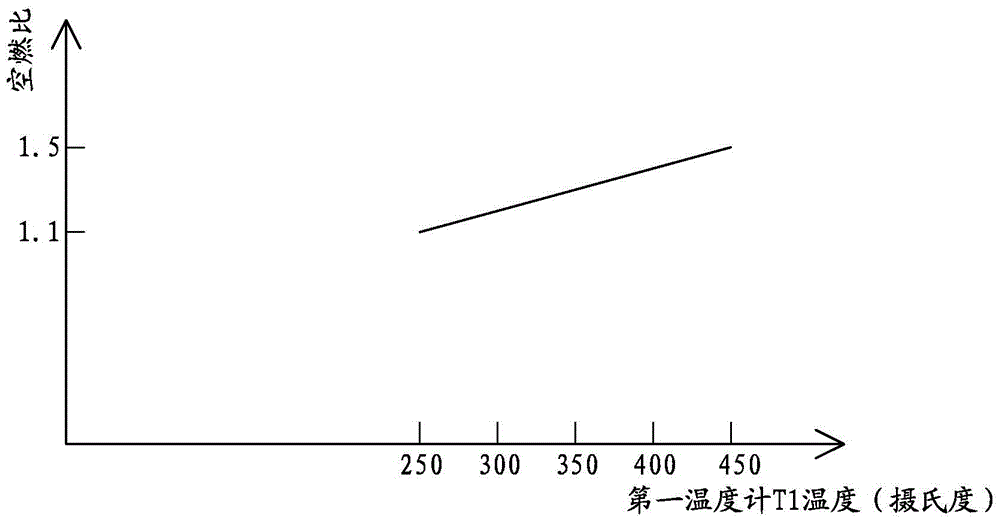

[0034] The high-temperature air plus high-temperature low-oxygen flue gas mixed combustion-supporting automatic control ceramic kiln of the present invention includes a thermocouple 121, a control box 122, and five nozzles 123 corresponding to each control zone. Wherein, the thermocouple 121 is arranged on the side wall of the kiln body of each control zone, so that the zone temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com