Boiler bottom structure of submerged scraper conveyor in thermal power plant

A thermal power plant and furnace bottom structure technology, applied to lighting and heating equipment, etc., can solve problems such as inability to realize temporary storage of slag and large slag crushing, tripping of boiler fire extinguishing unit, economic loss of power plant, etc., and achieve obvious water saving effect , Improved reliability, and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

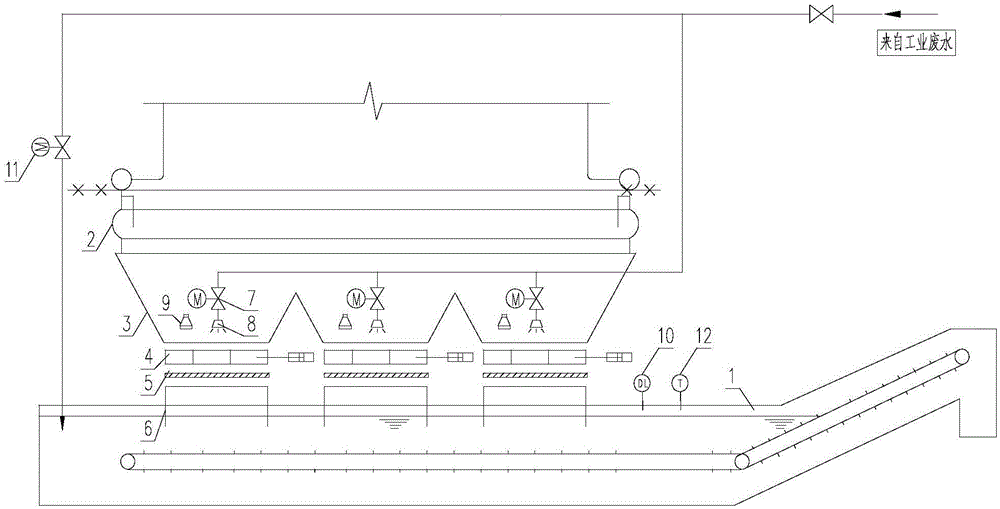

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] like figure 1 As shown, a transitional slag well 3 and a furnace bottom slag discharge device are provided between the boiler and the scraper slag extractor 1 . A mechanical seal device 2 is used to seal the bottom of the furnace between the transitional slag well 3 and the sealing plate of the lower header of the boiler water wall. Toothed extrusion head for crushing large slag. The mechanical seal device 2 can meet the requirements of long-term safe operation, withstand the maximum pressure of the furnace, absorb the displacement in all directions caused by the expansion of the boiler, and meet the harsh conditions such as high temperature and wear at the bottom of the boiler. The effective volume of the transition slag well 3 should be able to meet the maximum slag discharge capacity of the BMCR working condition boiler for more than 4 hours, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com