Preparation method of portable bone-china soup ladle

A bone china, lightweight technology, applied in the field of ceramics, can solve the problems of production technology limitations, no breakthrough improvements, etc., and achieve the effect of regular appearance, beautiful and light products, and smooth glaze layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

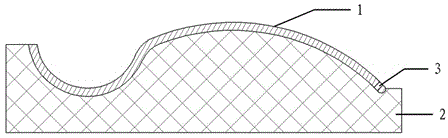

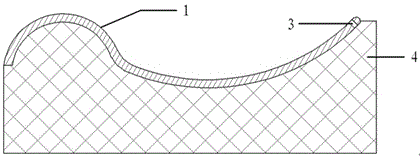

Image

Examples

Embodiment

[0034] The preparation method of bone china lightweight soup spoon comprises the following production steps:

[0035] (1) Blank preparation

[0036] Take 50 parts by weight of synthetic bone powder, 10 parts by weight of potassium feldspar, 8 parts by weight of quartz, 20 parts by weight of kaolin, 3 parts by weight of ball clay, 4 parts by weight of cordierite, and 7 parts by weight of waste porcelain as raw materials; into scrap bone china produced;

[0037] After mixing the above raw materials, add water to carry out wet ball milling. After ball milling, the raw materials are passed through a 220-mesh sieve. After passing through the sieve, the raw materials are removed through the iron remover, and the iron-removed raw materials are filtered into mud lumps through a filter press, and the mud lumps are passed through The mud refining machine is used for mud refining to prepare a billet with a mass moisture content of 22% for subsequent use;

[0038] (2) Glaze preparation:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com