LED product disc-type automatic braider

An automatic taping machine and taping machine technology, applied in packaging and other directions, can solve the problems of poor quality of LED materials, slow working speed of original packaging, and difficult to find details, etc., to achieve the effect of good positioning, low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

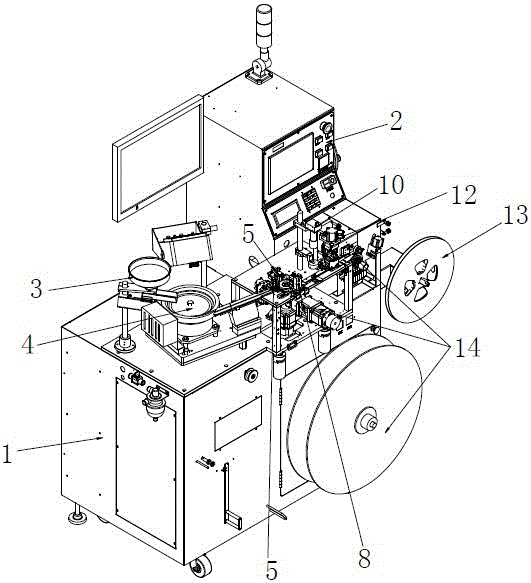

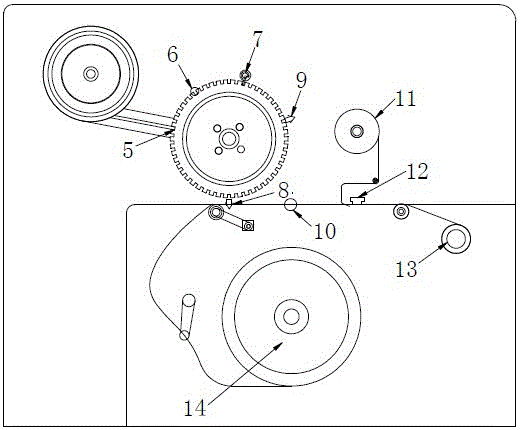

[0029] A disc-type automatic taping machine for LED products, the taping machine is composed of a machine 1 and a control system 2 installed on the machine 1, an automatic feeding system and a detection system, and the control system 2 adopts PLC Perform programming to control the electrical components of each system mechanism to operate according to the design requirements. The machine 1 is equipped with a man-machine interface and control buttons for production operation and control.

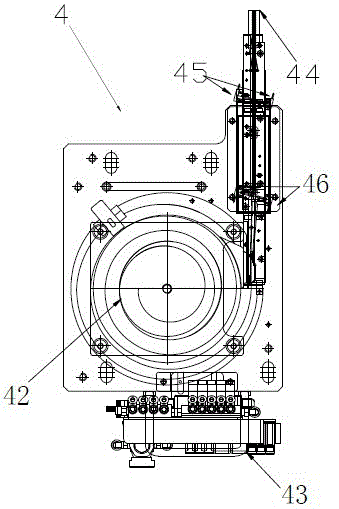

[0030]The feeding mechanism 4 is a vibrating plate 42 type feeding structure, mainly composed of a hopper 31, a vibrating plate 42, a controller 43 and a linear feeder 44. According to the classification of the traditional vibrating plate 42, the hopper 31 can be divided into a cylindrical hopper 31, a spiral, There are five types of line hopper 31, conical hopper 31, and equal line hopper 31. The present invention adopts five-axis processing spiral hopper 31, which has high precision and stabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com