Fuel drive multi-rotor fuel side flow preventing six-in-one fuel tank

A multi-rotor and fuel tank technology, applied in the direction of the fuel tank of the power unit, can solve the problems of flameout, affecting the flight and operation efficiency, and affecting the safety of the UAV, and achieve the effect of improving the fueling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

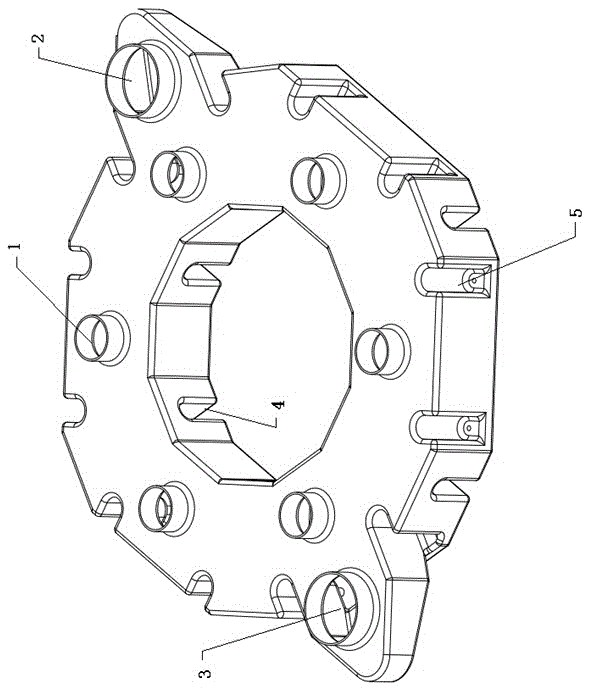

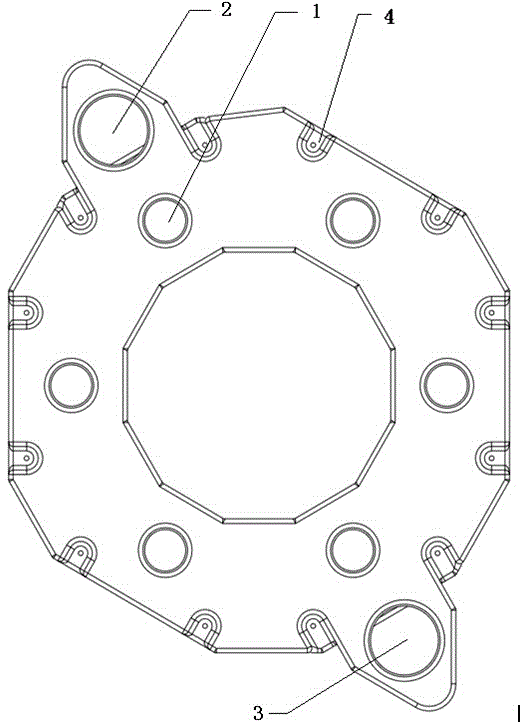

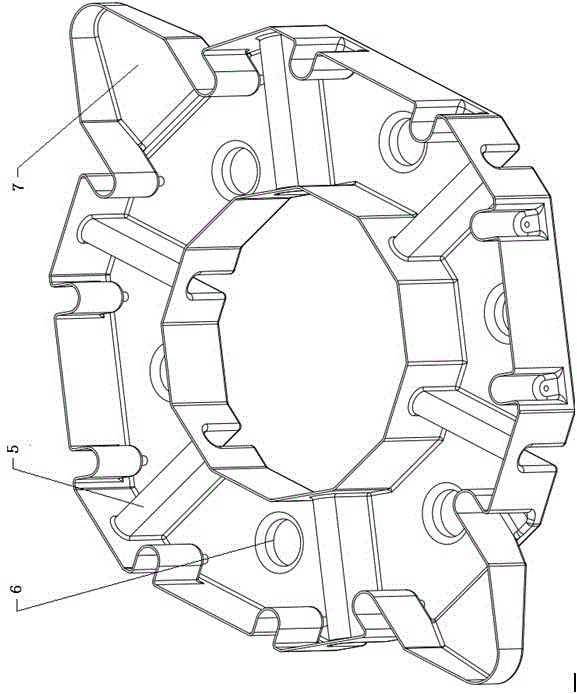

Embodiment 1

[0025] An oil-driven multi-rotor anti-fuel side-flow six-in-one fuel tank, the six small fuel tanks are evenly distributed on the circumference, including six oil outlets, an oil inlet and an oil overflow, the oil inlet and the overflow The oil ports are respectively arranged at one end of the two opposite small oil tanks, and the bottoms of the oil inlet and the oil overflow port are provided with inclined slopes. The oil tank also includes a bolt groove and a partition, the bolt groove is arranged on the outer edge of the oil tank, the oil storage tank at the bolt connection is arranged separately, and the partition is arranged in the oil tank to separate the six small oil tanks, The height of the partition of the partition is lower than the height of the fuel tank. The bottom of each small fuel tank is provided with a heavy hammer groove. The inside of the fuel tank is filled with a reticulated polyurethane foam layer. The surface of the fuel tank is coated with an anti-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com