Tunnel grouting trolley braking device and using method thereof

A braking device and trolley technology, applied in the direction of brakes, braking components, vehicle parts, etc., can solve the problems of mechanical equipment damage, large adjustable range of braking force, and inability to provide braking force, etc., to achieve adjustable bracket form, The braking force can be adjusted in a large range, and the effect of improving the efficiency of grouting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

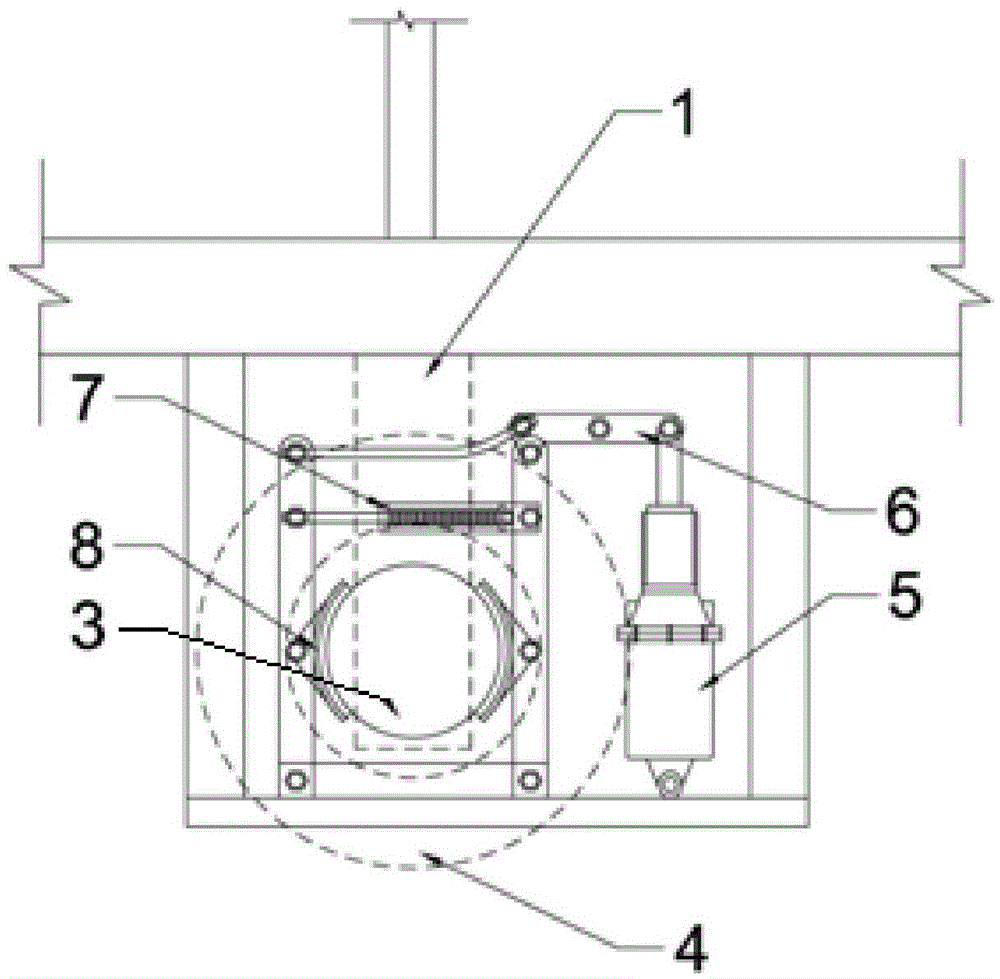

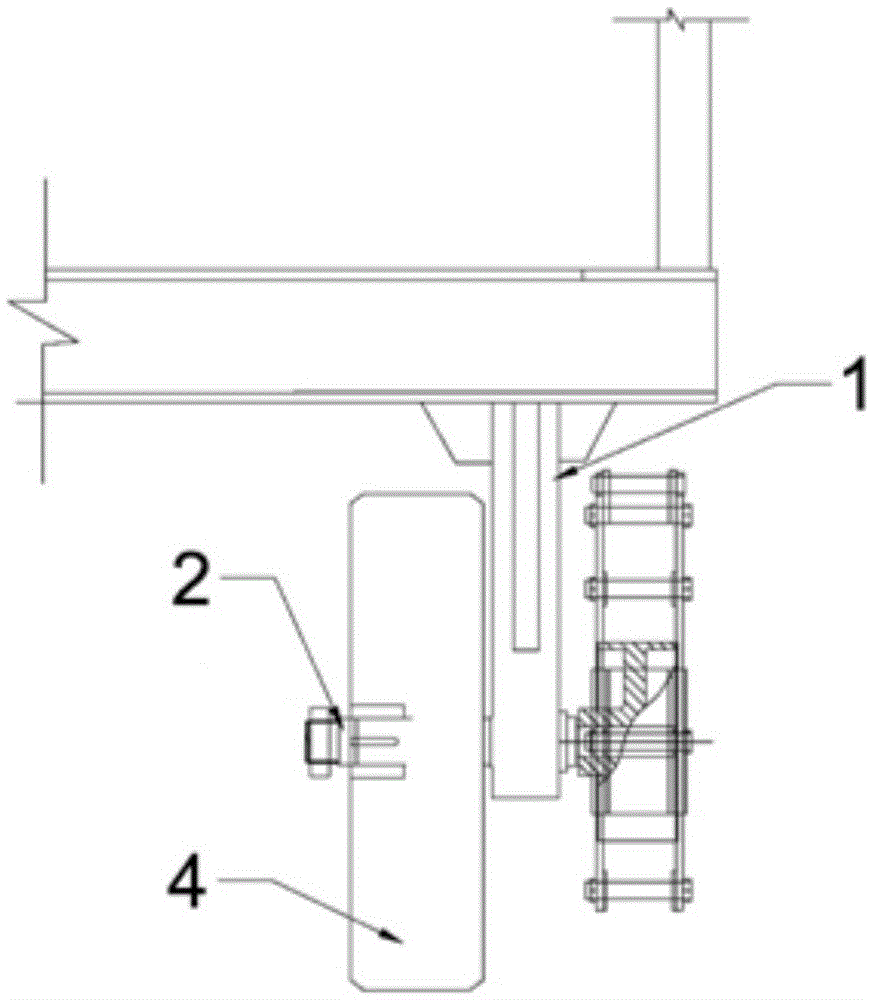

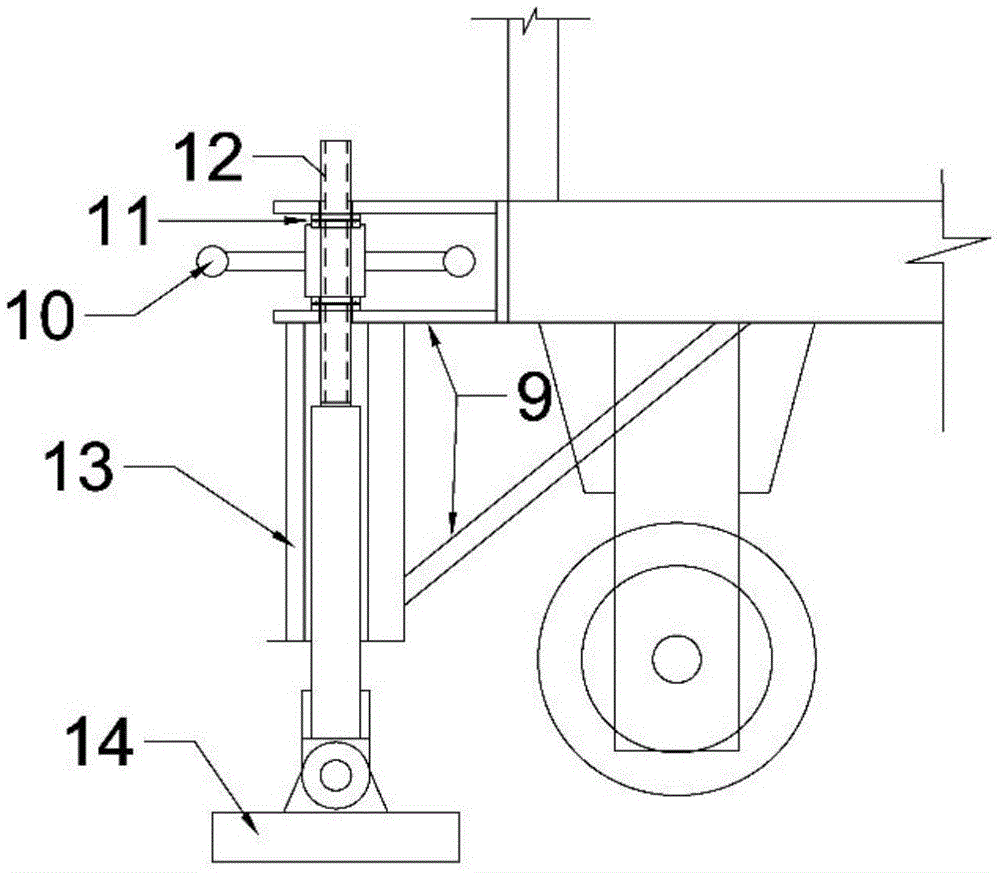

[0033] see Figure 1 to Figure 5 , a braking device for a tunnel grouting trolley, which is composed of a main braking device and an auxiliary braking device. The main braking device includes a tire support 1, an axle 2, a brake wheel 3, a tire 4, an electric hydraulic pump 5, a dowel bar 6, a brake spring 7, and a brake 8. The weight of the upper part of the trolley is transmitted to the tire 4 through the tire bracket 1-axle 2; the brake spring 7 is in a pre-tightened state when the electric hydraulic pump 5 is not working, and the brake 8 at this time holds the brake wheel 3 tightly, and the brake 8 Friction will be generated between the brake wheel 3 and the rotation of the brake wheel 3 will be limited. Since the brake wheel 3 and the tire 4 are connected by the axle 2, when the brake wheel 3 does not rotate, the tire 4 will not be able to rotate , at this mome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com