Blue light photocuring 3D printing pen

A 3D printing pen and blue light technology, applied in the direction of 3D object support structure, processing and manufacturing, manufacturing tools, etc., can solve the problems of potential safety hazards, easy burns for users, etc., and achieve fast curing speed, time saving and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

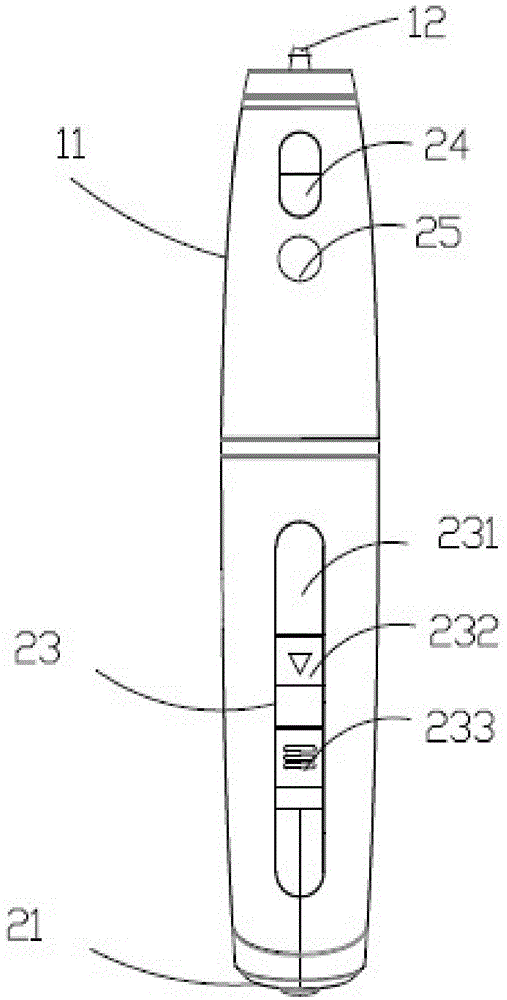

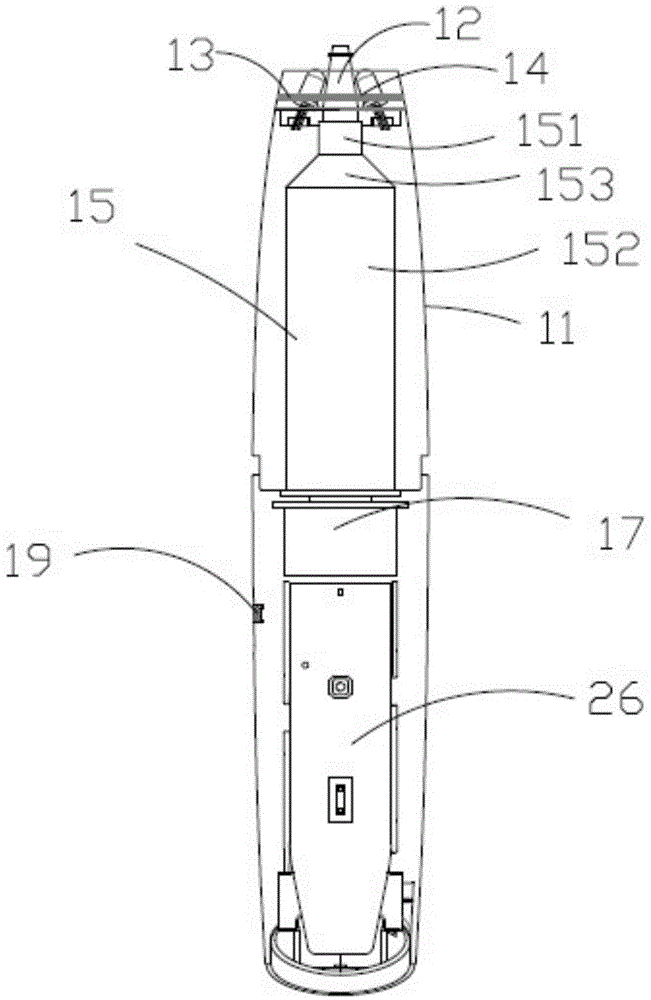

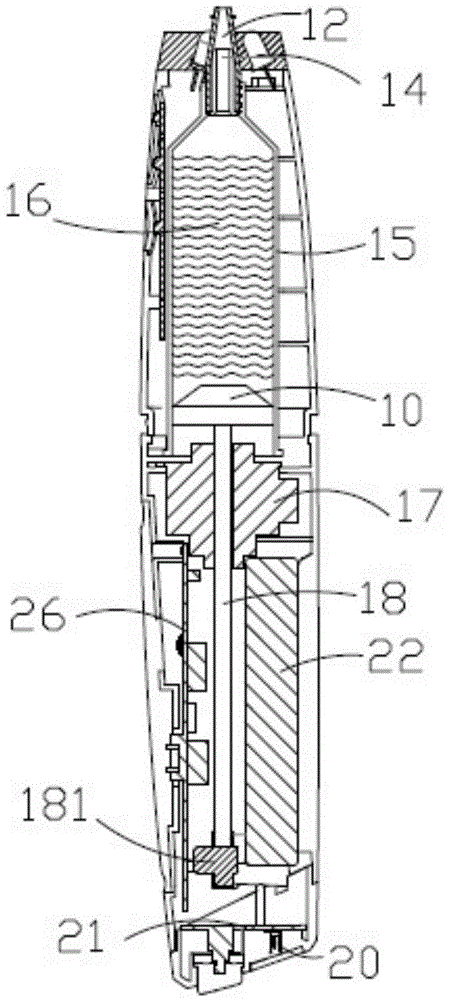

[0025] The present invention is a blue-ray photocuring 3D printing pen. The working mechanism of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as Figure 1 to Figure 5 As shown, the blue light curing 3D printing pen includes a casing 11, an ink cartridge 15 installed in the casing 11, a nib 12 installed in the front end of the ink cartridge 15 and extending out of the casing 11, and several blue LEDs (light emitting diodes) arranged around the front end of the ink cartridge 15. ) 14, the piston 10 that is installed in the ink cartridge 15 and slides forward in the ink cartridge 15, the photosensitive resin 16 placed in the ink cartridge 15, the stepping motor 17 that drives the piston 10 to move forward, runs through the stepping motor 17 and resists Connected to the threaded push rod 18 of the piston 10, the battery 22 installed at the rear end of the stepper motor 17, the main control board 26, the power sw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com