Groove milling method of whole large material of IC cards and groove milling device implementing groove milling method

A slot milling device and slot milling technology, which is applied to milling machine equipment, details of milling machine equipment, metal processing equipment, etc., can solve problems such as wasting time, limited number of milling slots, difficulty in controlling the relative position accuracy of IC card milling slots, etc., and achieve positioning Accurate, improve efficiency, and save delivery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

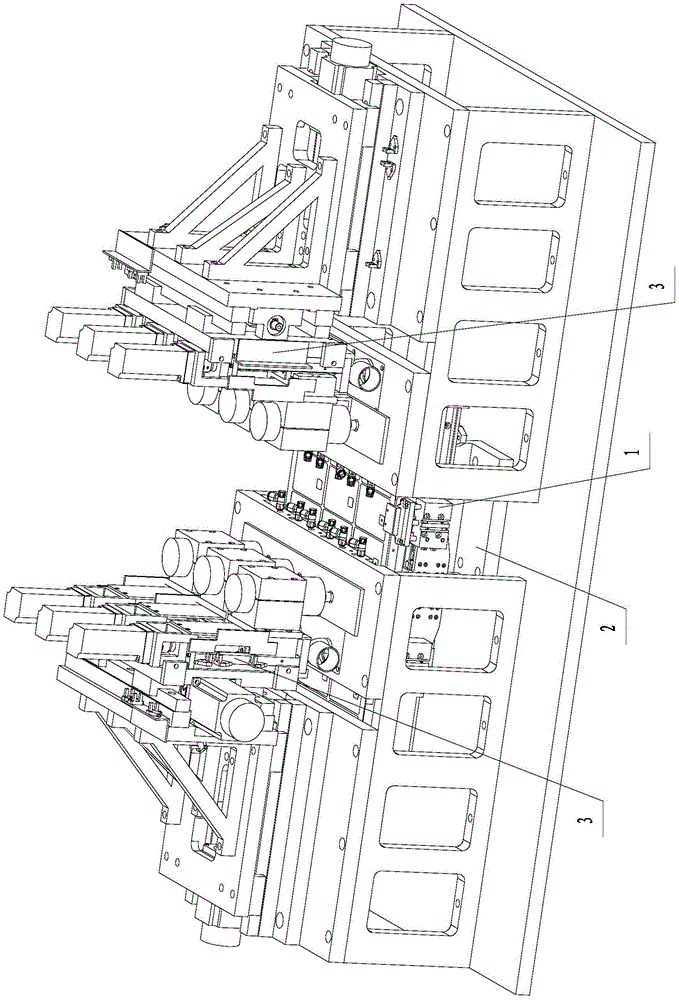

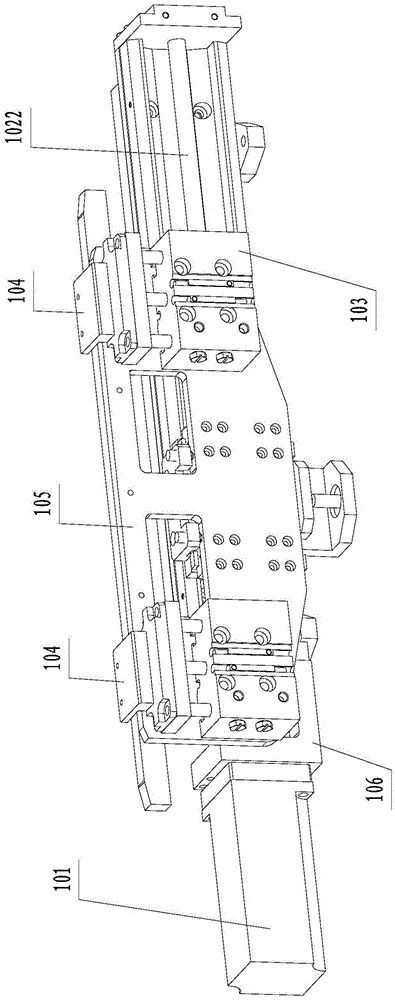

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] The present invention changes the card making process sequence and form, and changes the production process into: printing of raw materials—synthesis of M×N whole sheets—grooves milling—packaging—personalization—cutting.

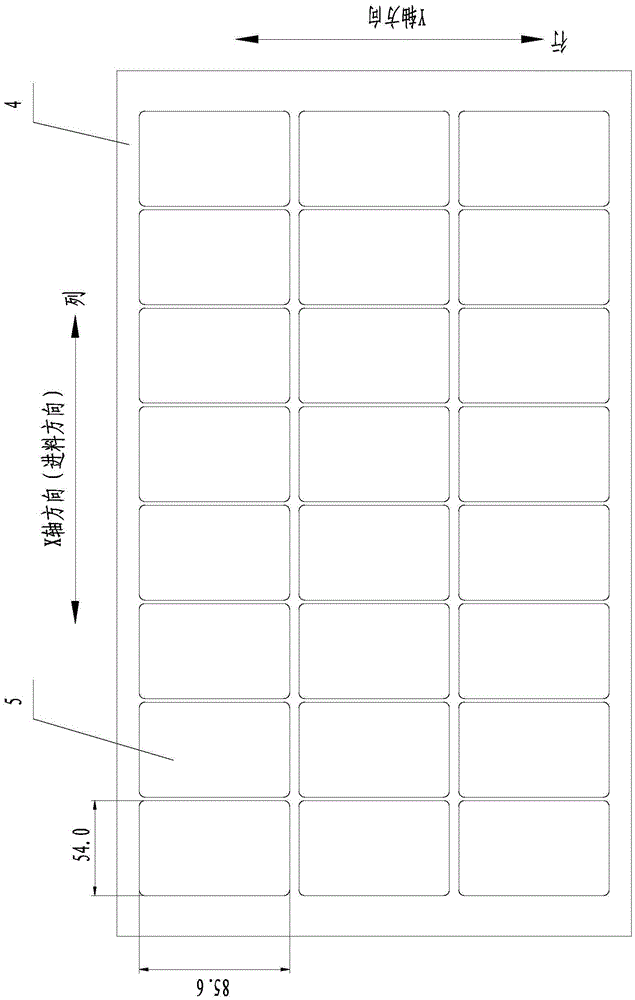

[0035] The present invention directly carries out groove milling to the whole aniseed material 4, wherein the whole aniseed material 4 is as figure 1 As shown, ISO7816 standard cards with a size of 85.6mm×54mm are reasonably distributed on the entire big material 4 by typesetting the ISO7816 standard cards. The specific size of the whole big material 4 depends on the printable range. In the two-dimensional space, set the X axis as the row and the Y axis as the column, and the short side of the ISO7816 standard card is 54mm parallel to the X axis, and the long side 85.6mm is parallel to the Y axis. on the X-axis. The number of 4-arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com