Novel square billet continuous casting secondary cooling water adjusting structure

A billet continuous casting and structure-adjusting technology, which is applied in the field of secondary cooling of billet continuous casting, can solve the problems of inability to finely adjust the amount of cooling water, poor cooling effect, etc., so as to improve the quality of the billet, reduce equipment costs, and improve equipment composition. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

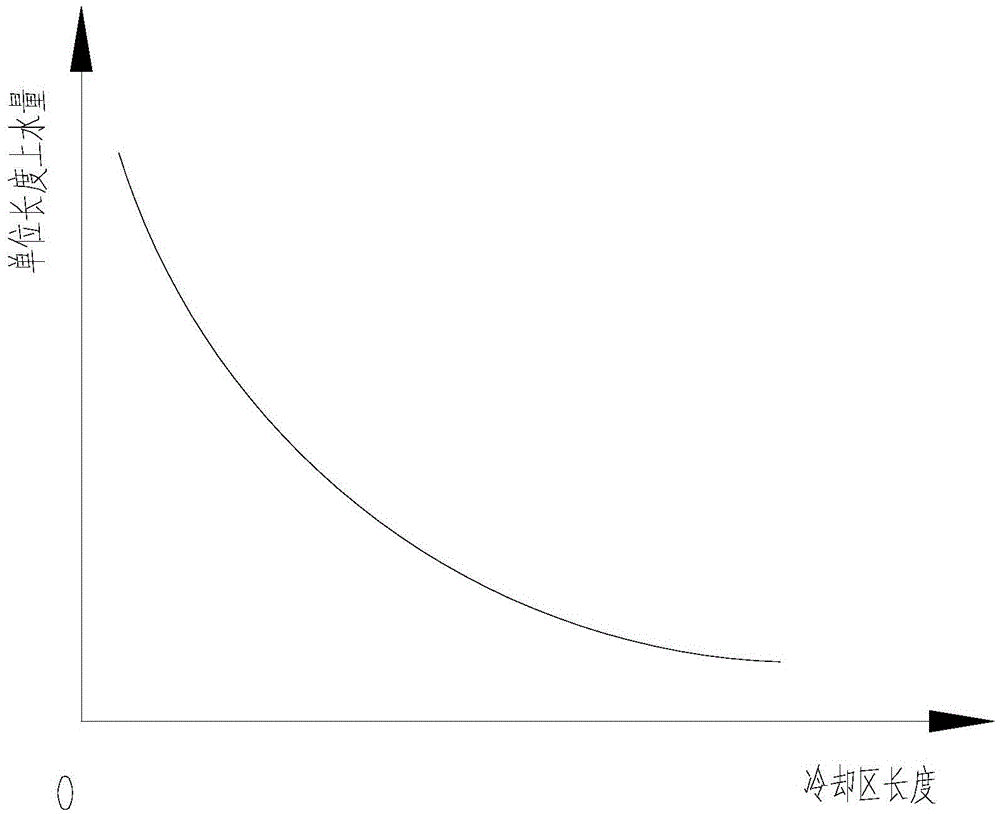

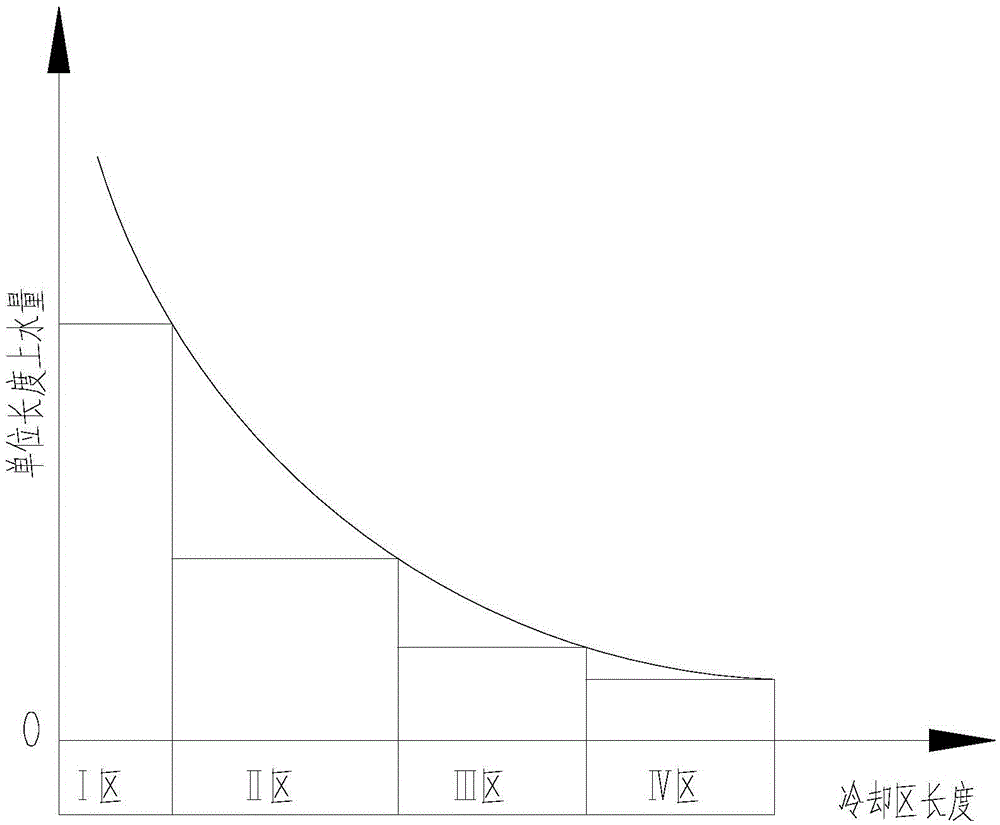

[0038] Such as figure 1 Shown, the theoretical density distribution of spray cooling water. The abscissa in the figure is the length of the cooling zone, the ordinate is the cooling water volume per unit length, and the curve is the theoretical secondary cooling water density distribution. In order to obtain good slab quality, theoretically it is required that the distribution of the secondary cooling water gradually decreases from top to bottom along the casting direction, and the water density distribution curve on the surface of the slab is smooth and continuous.

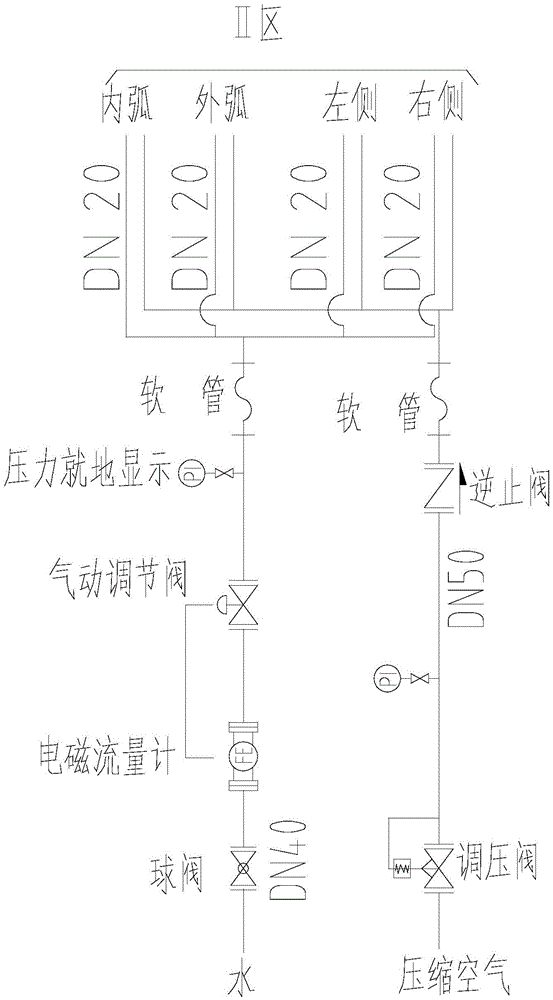

[0039] Such as figure 2 As shown, the system schematic diagram of spraying cooling water after the existing secondary cooling zone control. Taking the secondary cooling zone II as an example, the current secondary cooling adopts air-water cooling. The cooling water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com