Tool used for bending robot

A robot and tooling technology, applied in the direction of feeding devices, manufacturing tools, positioning devices, etc., can solve problems such as jamming, easy to shake up and down, lack of support platforms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

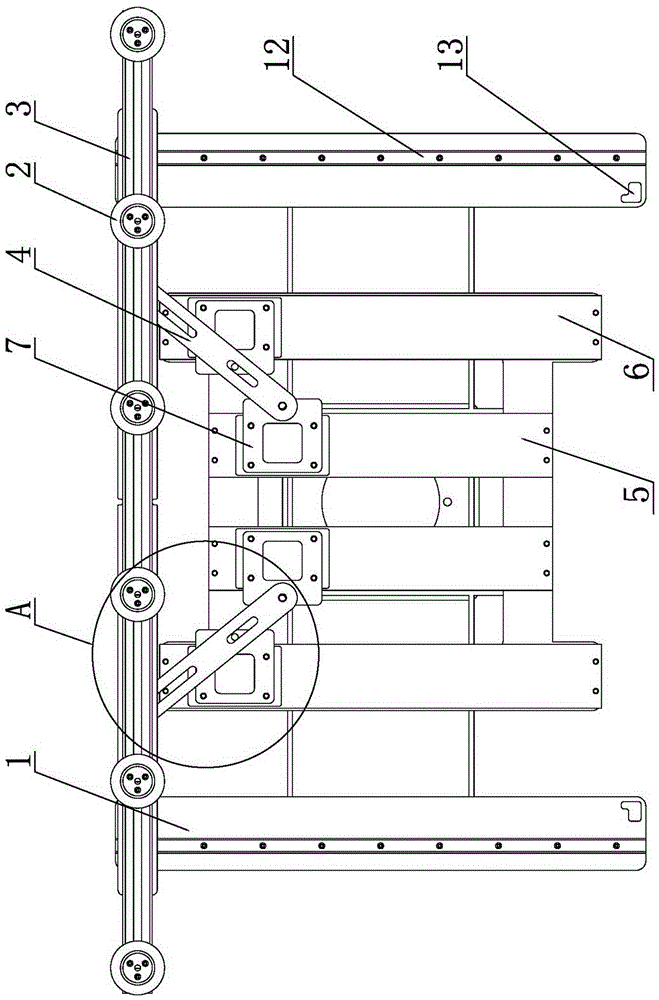

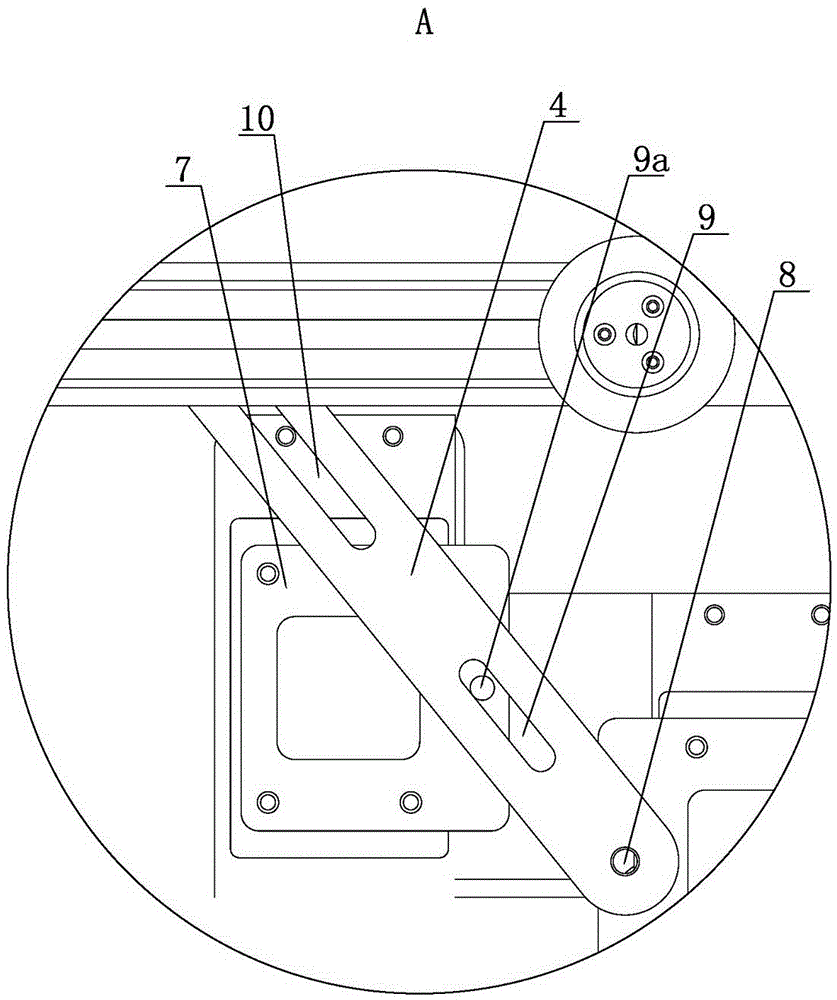

[0021] Such as Figure 1-7 As shown, it is a tooling for a bending robot, including a base 1 connected to the motor shaft at the end of the mechanical arm 16. The base 1 is connected with a suction cup bracket 3 with several suction cups 2 mounted on the surface. The suction cup bracket 3 is made of aluminum The material is integrally extruded and formed. The suction cup bracket 3 is long and has notches around it. The suction cups 2 are fixedly clamped in the slots on the upper side of the suction cup bracket 3; the suction cups 2 on the suction cup bracket 3 are arranged evenly in a single row; the base 1 is also fixedly installed with a cylinder that drives the suction cup support 3 to move through the swing rod 4. The corresponding suction cup support 3 is provided with a guide groove on the swing rod 4. The cylinder includes two intermediate cylinders 5 that are symmetrically arranged in the middle of the base 1. The base 1 Corresponding to each middle cylinder 5, there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com