An online homogenization device for magnetorheological polishing fluid

A magnetorheological polishing and chemical device technology, which is applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve problems affecting the homogenization of magnetorheological fluid components and distribution uniformity, and achieve Avoid shear thinning, improve reliability, and avoid settlement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

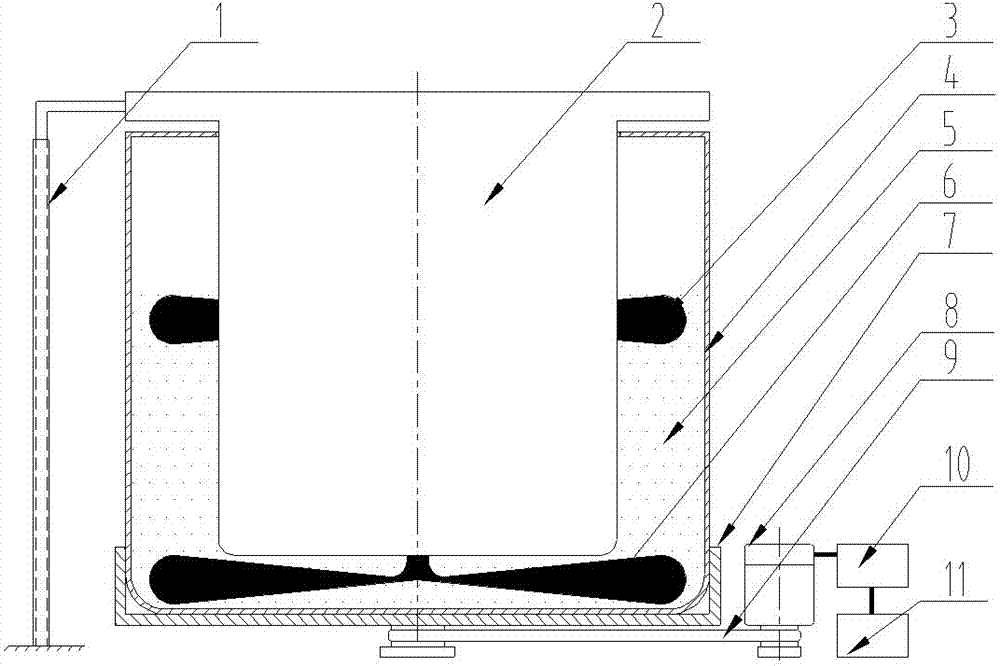

[0016] figure 1 It is the principle diagram of the online homogenization device for magnetorheological polishing fluid of the present invention. exist figure 1 Among them, a magnetorheological polishing liquid online homogenization device of the present invention includes a cylinder 1, a transfer pump body 2, a reverse paddle 3, a liquid storage tank 4, a magnetorheological polishing liquid 5, a positive paddle 6, and a tray 7 , homogenization motor 8, belt pulley 9, homogenization motor driver 10, timing controller 11, the connection relationship is that the cylinder 1 is connected with the transmission pump body 2 and supports the transmission pump body 2, and the bottom of the transmission pump body 2 passes through The positive paddles 6 are connected and fastened by screws, and the reverse paddles 3 are connected and fastened on the outer circular wall of the middle part of the delivery pump body 2 by screws. The delivery pump body 2 is placed in a liquid storage tank 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com