Deep purification method and device of flue gas after wet-process desulfurization

A technology for deep purification and wet desulfurization of flue gas, which is applied in chemical instruments and methods, combined devices, separation methods, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments. In the following detailed description, certain exemplary embodiments of the invention are described by way of illustration only. Needless to say, those skilled in the art would realize that the described embodiments can be modified in various different ways, all without departing from the spirit and scope of the present invention. Accordingly, the following description is illustrative in nature and not intended to limit the scope of the claims.

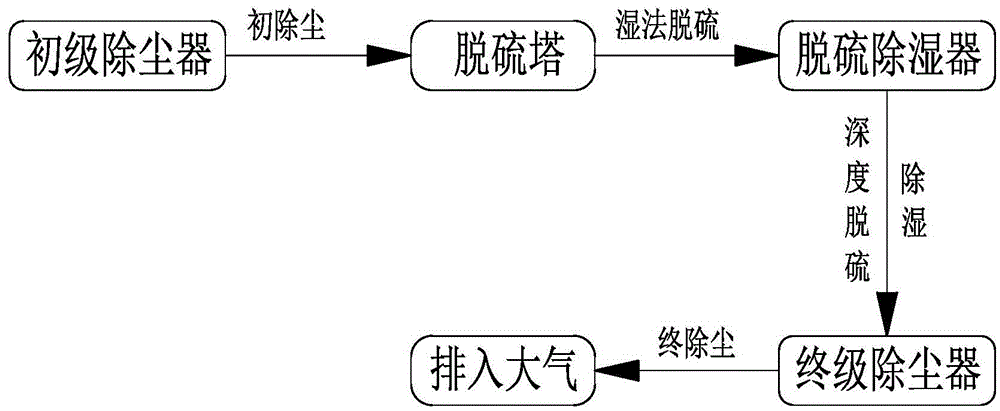

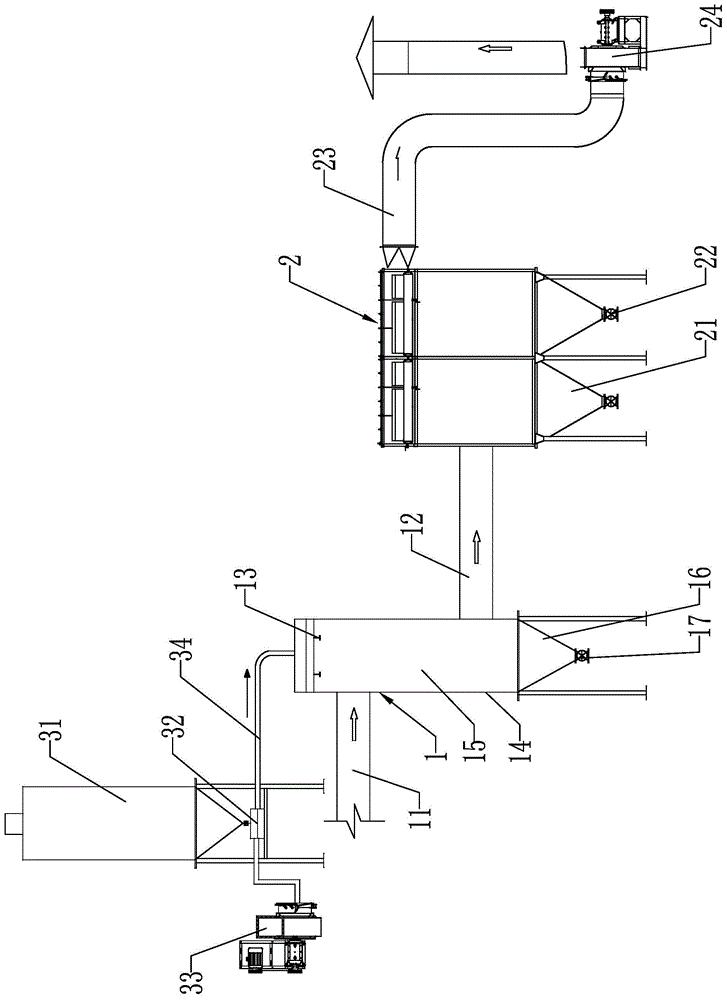

[0029] like figure 1 and figure 2 As shown, the method for deep purification of flue gas after wet desulfurization includes the following steps:

[0030] Step 1. Preliminary dust removal of flue gas: flue gas containing sulfur and dust first enters the primary dust collector (electrostatic precipitator or bag filter can be used), is captured and filtered, then falls into the ash hopper, and is discharged from the discharge valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com