A kind of soy sauce brewing method using enzyme preparation to improve amino acid yield

An enzyme preparation and amino acid technology, applied in food science and other directions, can solve the problems of insignificant improvement of soy sauce flavor, long preparation time, and low enzyme activity, so as to improve the utilization rate of protein, simple preparation method and short fermentation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

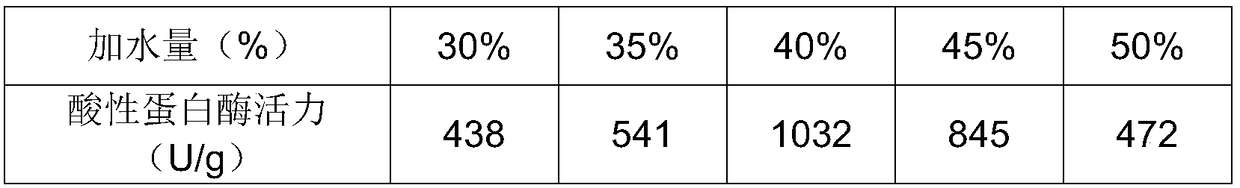

[0038] 1. The effect of the ratio of excipients on the activity of enzyme preparation acid protease

[0039] The desalted sauce residue and bran are evenly mixed to make seed koji, wherein the proportions of bran are adjusted to 30%, 40%, 50%, and 60% respectively, the inoculum amount of Aspergillus niger is 0.5‰, and the amount of water added is equal to the total weight of the seed koji. 50%, the culture temperature is: control the temperature at 28°C for 0-6h, control the temperature at 35°C for 6h-18h, and then loosen the koji for the second time at 18h, lower the temperature of Daqu to 30°C, and measure the acid protease activity of the enzyme preparation respectively.

[0040] Table 1 The influence of bran ratio on the enzyme activity of enzyme preparation

[0041] percentage(%)

[0042] It can be seen from Table 1 that when the addition ratio of bran is less than 50%, the activity of the enzyme acid protease increases with the increase of the addition ratio, mai...

experiment example 2

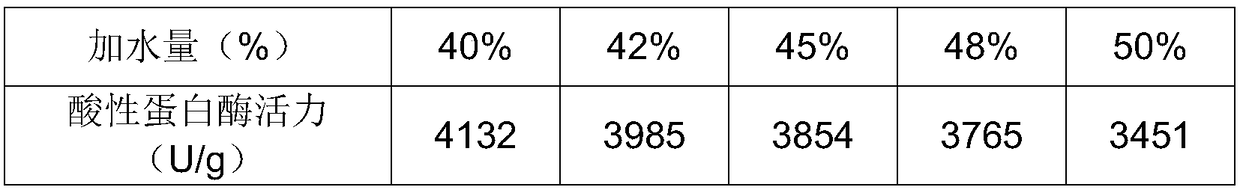

[0055] 1. The effect of the ratio of excipients on the activity of enzyme preparation acid protease

[0056] The desalted sauce residue and bran are uniformly mixed to make seed koji, and the proportion of bran is adjusted respectively to determine the appropriate medium ratio. Adjust the proportion of bran to 50%, 52%, 55%, 58%, and 60%, the inoculation amount of Aspergillus niger is 0.5‰, the amount of water added is 40% of the total weight of the seed koji, and the cultivation temperature is: 0~6h temperature control 28 ℃, 6h ~ 18h temperature control 40 ℃, 18h after the second loose song, lower the temperature of Daqu to 30 ℃, respectively measure the acid protease activity of the enzyme preparation.

[0057] The influence of table 4 bran proportion on enzyme preparation enzyme activity

[0058]

[0059] It can be seen from Table 4 that when the addition ratio of bran is 52%, the acid enzyme activity of the enzyme preparation reaches the highest value, so the addition ...

experiment example 3

[0066] 1. Determination of the preparation temperature of the enzyme preparation for 6h to 18h

[0067] In the process of large-scale production and ventilated koji making, in order to ensure that Aspergillus niger becomes the dominant strain and reduce the production of bacteria, the temperature is controlled at 28-30°C for 0-6 hours in the early stage, and 6-18 hours is the most vigorous growth stage of Daqu. For the second pine song, reduce the temperature of Daqu to 30-32°C, the optimum temperature for Aspergillus niger to produce enzymes. Therefore, it is necessary to adjust the temperature between 6 and 18 hours to determine the suitable temperature for preparing the enzyme preparation: mix the desalted sauce residue and bran evenly to make seed koji, the ratio of desalted sauce residue to bran is 1:1, Aspergillus niger The amount of inoculation is 0.5‰, the amount of water added is 50% of the total weight of the seed koji, and the culture temperature is: 0~6h temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com