Food preservation pad and preparation method thereof

A food preservation, non-woven layer technology, applied in chemical instruments and methods, preservation of meat/fish with chemicals, layered products, etc., can solve problems such as expensive equipment, delay increase, inhibit growth, and extend shelf life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: food preservation pad and preparation method thereof

[0026] The present invention will be further described below in conjunction with the accompanying drawings, and embodiments of the present invention will be given.

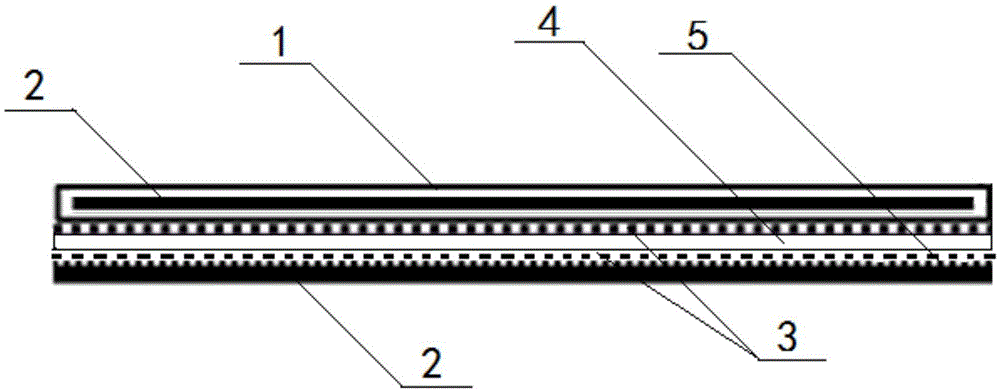

[0027] Such as figure 1 This food preservation mat shown comprises two layers of non-woven fabric layers 2 and a water-soluble polyvinyl alcohol film layer 4 sandwiched between the two layers of non-woven fabrics, and the outer surface of the upper non-woven fabric layer is coated with Sodium alginate film layer 1 with antibacterial function, the outer surface of the water-soluble polyvinyl alcohol film layer 4 is coated with a carbon dioxide release reactant material layer 3, and the upper surface of the lower non-woven fabric layer is clothed with adhesive The food-grade water-absorbing agent that is bonded and evenly distributed; the upper and lower non-woven fabric layers 2 and the water-soluble polyvinyl alcohol film layer 4 are bond...

Embodiment 2

[0041] Embodiment 2: food preservation mat and preparation method thereof

[0042] Please see figure 1 , figure 1 It is a structural schematic diagram of a food preservation mat of the present invention.

[0043](1) Preparation of antibacterial layer

[0044] A 2% (w / v) calcium chloride solution was first prepared.

[0045] Weigh 0.33g of microcrystalline cellulose and 1.63g of potassium sorbate into 1000ml of distilled water, stir evenly with magnetic force at room temperature, disperse ultrasonically for 30 minutes, then add 30g of sodium alginate, stir well in a water bath at 75°C, and cool to Add 0.33g sodium polyacrylate and 0.33g glycerin to it after room temperature, fully stir evenly under room temperature, ultrasonically disperse for 30 minutes, then put the mixed solution into a vacuum drying oven to remove the air bubbles therein, and obtain a uniform mixture.

[0046] Cut the non-woven fabric with a size of 160mm×100mm, and firstly treat the upper and lower su...

Embodiment 3

[0052] Embodiment 3: food preservation mat and preparation method thereof

[0053] Please see figure 1 , figure 1 It is a structural schematic diagram of a food preservation mat of the present invention.

[0054] (1) Preparation of antibacterial layer

[0055] A 2% (w / v) calcium chloride solution was first prepared.

[0056] Weigh 2g of microcrystalline cellulose and 5.2g of potassium sorbate into 1000ml of distilled water, stir evenly with magnetic force at room temperature, disperse ultrasonically for 30 minutes, then add 30g of sodium alginate, stir well in a water bath at 75°C, and cool to room temperature Then add 2g sodium polyacrylate and 0.8g glycerin to it, stir well at room temperature, ultrasonically disperse for 30 minutes, put the mixed solution in a vacuum drying oven to remove the air bubbles therein, and obtain a uniform mixed solution .

[0057] Cut the non-woven fabric with a size of 160mm×100mm, and firstly treat the upper and lower surfaces of the non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com