Environment-friendly dinotefuran microemulsion free of organic solvent and preparation method thereof

A dinotefuran microemulsion and an environment-friendly technology, applied in the field of environment-friendly dinotefuran microemulsion and its preparation, can solve the problems of large technical difficulty, large amount of organic solvent, poor environmental protection performance of emulsifier and the like, and achieve stable storage. , Improve the effect of environmental friendly performance and strong production operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

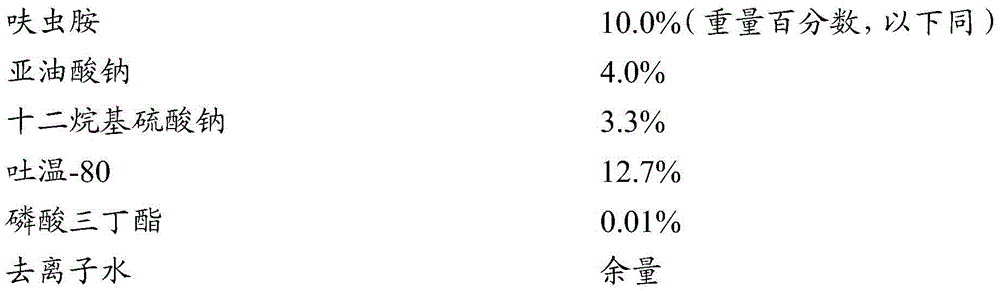

[0053] Example 1 A 10% organic solvent-free environmentally friendly dinotefuran microemulsion

[0054] Raw material ratio:

[0055]

[0056] Prepared by:

[0057] 1. prepare various raw materials for preparing 1000kg microemulsion according to formula weight ratio;

[0058] II. Add sodium linoleate, sodium lauryl sulfate, and Tween-80 to the stirring tank respectively, add deionized water, stir, and dissolve;

[0059] III. Add dinotefuran, stir, and make it dissolve to obtain a transparent solution;

[0060] IV. Then add tributyl phosphate defoamer, stir slightly, stand still, and filter to get the target product with a transparent appearance. For the sample photo, see figure 1 .

[0061] The samples were tested and found to meet the specified quality standards. The test items, methods and results are shown in Table 1.

[0062] Table 110% dinotefuran microemulsion testing items, testing methods and quality standards

[0063]

Embodiment 2

[0064] Example 2 A 5% Organic Solvent-Free Environmentally Friendly Dinotefuran Microemulsion

[0065] Raw material ratio:

[0066]

[0067] Adopt the preparation method and steps similar to Example 1, obtain 1000kg target product, see sample figure 1 .

Embodiment 3

[0068] Example 3 1%~9% Environmentally Friendly Dinotefuran Microemulsion Without Organic Solvent

[0069] Take 100kg of the 10% organic-solvent-free environment-friendly dinotefuran microemulsion obtained in Example 1, add different amounts of water as shown in Table 2, and stir to obtain 1% to 9% organic-solvent-free environment-friendly dinotefuran Amine microemulsion.

[0070] Table 2 dilution water consumption and obtain corresponding microemulsion concentration

[0071]

[0072] According to the above method, when different amounts of water are added to the 10% dinotefuran microemulsion, the system becomes a uniform and transparent solution without turbidity, precipitation and the like after a little stirring. It shows that dinotefuran with high concentration (10%) is uniformly and stably dispersed in the microemulsion of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com