Distributing valve and gasket

A distribution valve and valve column technology, applied in the direction of fluid distribution valve, distribution device, multi-way valve, etc., can solve the problems of increased user burden, expensive distribution valve, large space for distribution valve installation, etc., and achieves good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A plurality of embodiments related to the distribution valve of the present invention will be sequentially described with reference to the drawings.

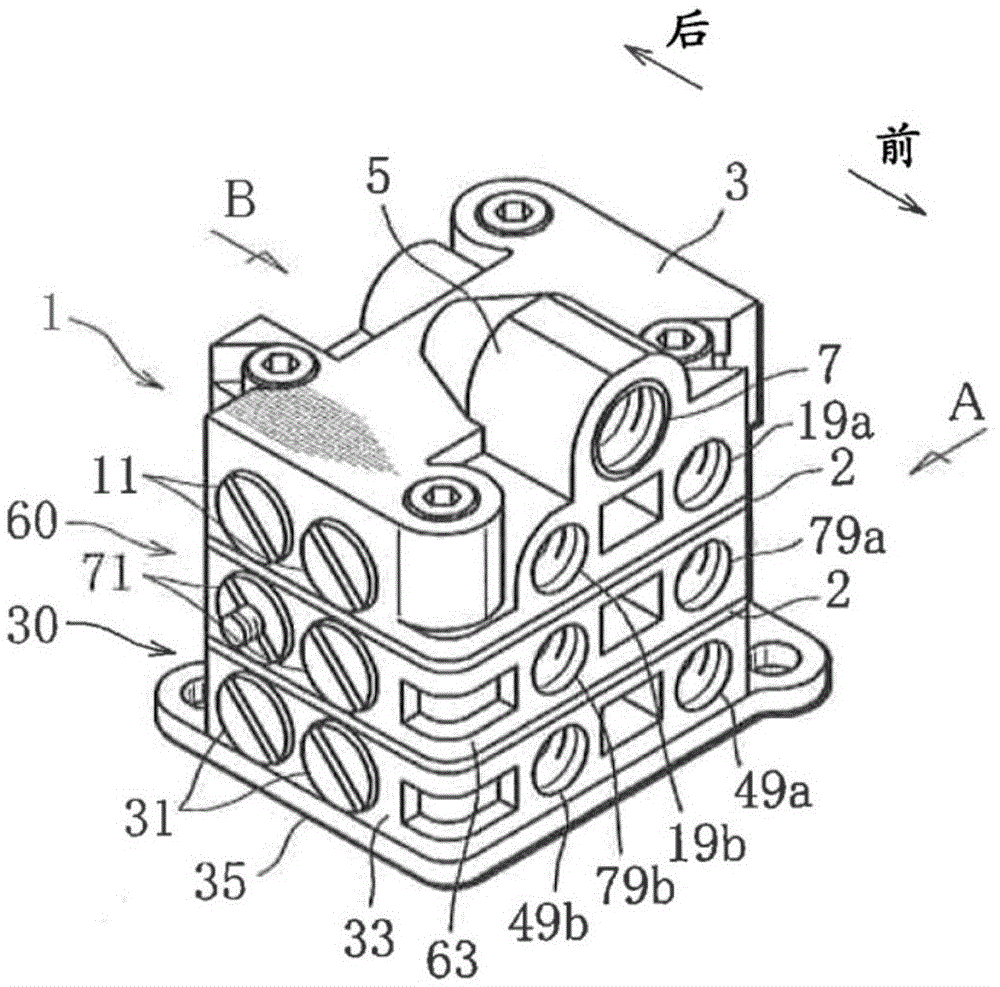

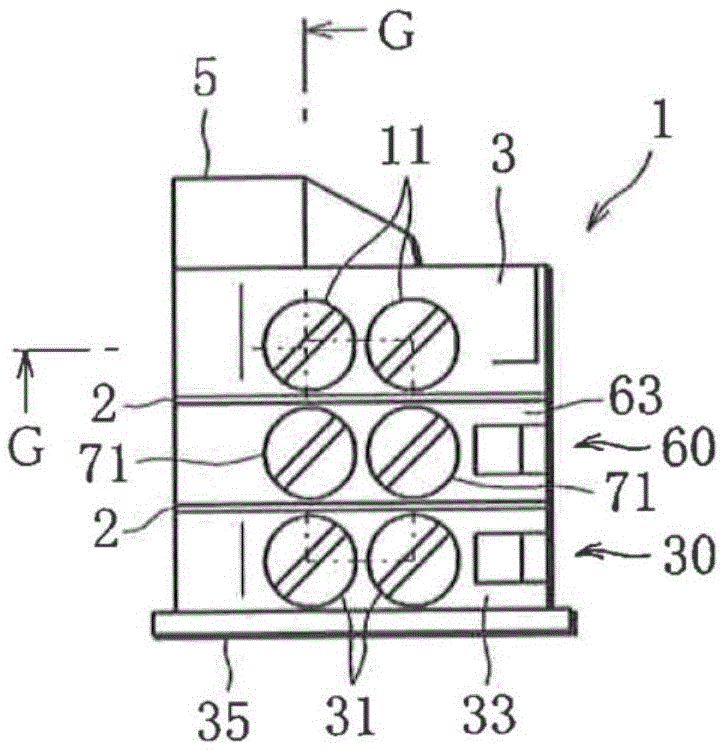

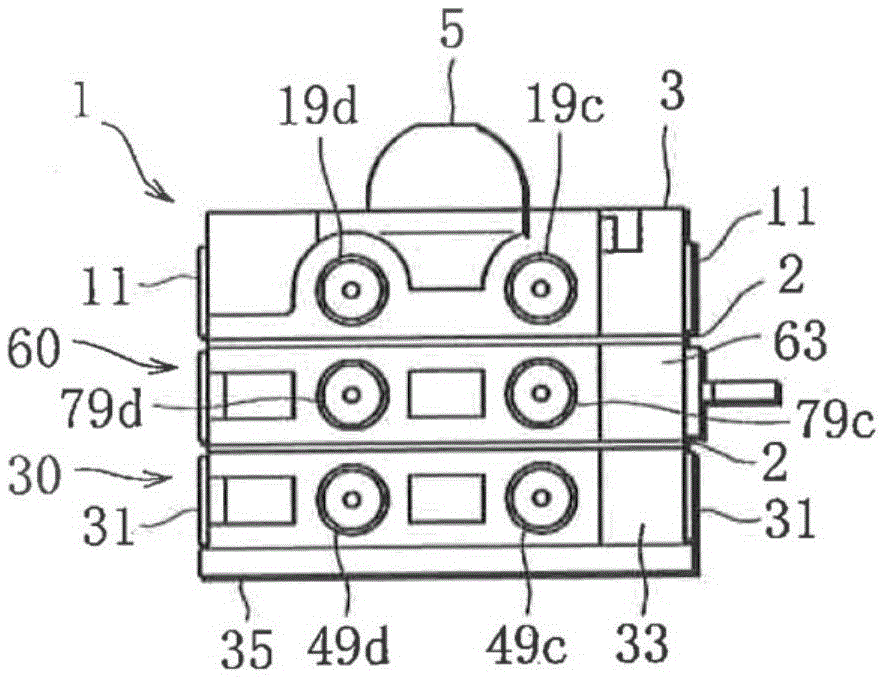

[0038] figure 1 A perspective view of the distribution valve according to the first embodiment is shown, and the distribution valve is used to distribute fluid. The fluid here may have viscosity, and examples of such a viscous fluid include lubricants such as grease. figure 2 as well as image 3 Respectively show the side and back of the above distribution valve, Figure 4 The main features of the distribution valve according to the present invention are clearly shown.

[0039] From Figure 1 ~ Figure 3 It can be seen that the distribution valve of the first embodiment includes: a top block (first block) 1, a bottom block (second block) 30, and a single intermediate block (third block) 60 arranged between the blocks 1 and 30. . Among the above-mentioned blocks 1, 30, 60, the top block 1 is arranged at the top, and on the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com