Overhead power transmission line laying device

A technology of transmission lines and transmission devices, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of personal and equipment injury accidents, the inability to accurately and effectively ensure the accuracy and self-heavyness of power cables, and reduce construction risks and labor intensity , Improve erection efficiency and erection quality, good sag and tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

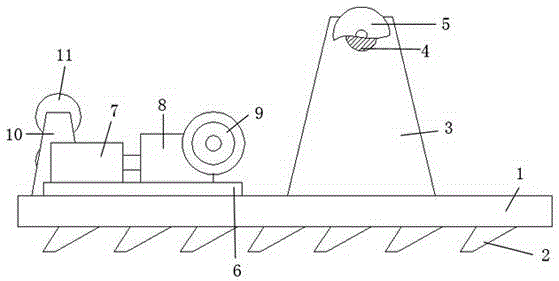

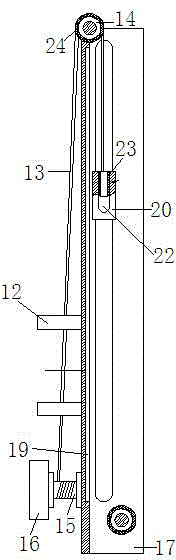

[0012] Such as figure 1 The above-mentioned upper-line device for a suspended transmission line is composed of a pay-off table and an upper wire frame, and there are at least two upper wire frames. Evenly distributed wedge-shaped anti-skid groove 2, the upper surface is respectively connected with the hinge frame, the guide wheel group and the driving mechanism, wherein the hinge frame is composed of a column 3 and a beam 4, and the column 3 is perpendicular to the base 1 and the beam 4 respectively, and the end of the beam 4 is separately provided Block 5, drive mechanism is made of positioning plate 6, drive motor 7, transmission 8 and drive wheel 9, drive motor 7, transmission 8 and drive wheel 9 are all installed on the positioning plate 6, and drive motor 7 passes through transmission 8 are respectively connected with the driving wheel 9 and the lead wheel group, the positioning plate 6 is connected with the base 1 through bolts, the lead wheel group is composed of a fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com