Numerical simulation determination method of deep high-stress roadway drilling pressure relief parameter

A determination method and drilling pressure relief technology, applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of rarely considering the attenuation process of rock strength parameters after peaks, affecting the output of calculation results, and ignoring the diameter of the borehole. Problems such as the interaction relationship with the spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

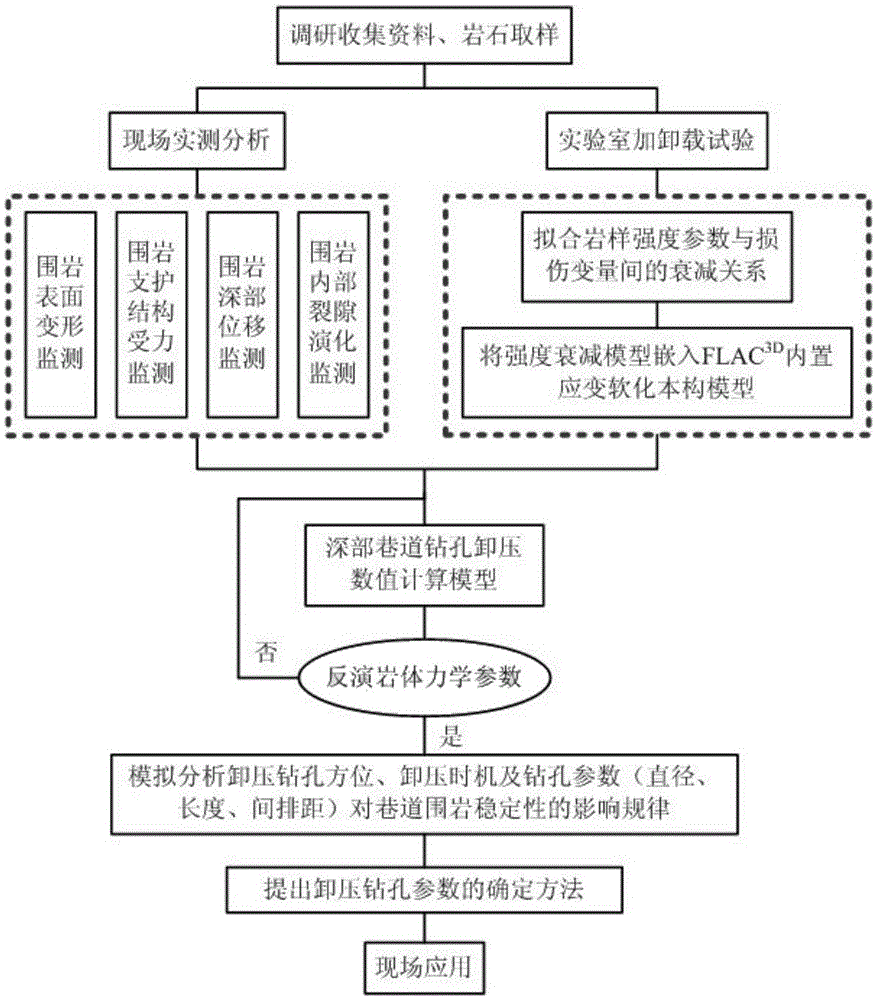

Method used

Image

Examples

Embodiment 1

[0084] Embodiment Take the production geological conditions and roadway support engineering practice of Zhangshuanglou Coal Mine of Xukuang Group as an example. The average buried depth of the roadway in this project is 1030m. * height) is 4.8m * 4.4m, adopt the technology of the present invention to design the roadway drilling pressure relief parameters. The method for determining the numerical simulation of the drilling pressure relief parameters in this example includes the following steps:

[0085] 1) According to the engineering scheme of this embodiment, the complete surrounding rock of the test roadway is drilled and sampled, and the loading and unloading test is carried out in the laboratory:

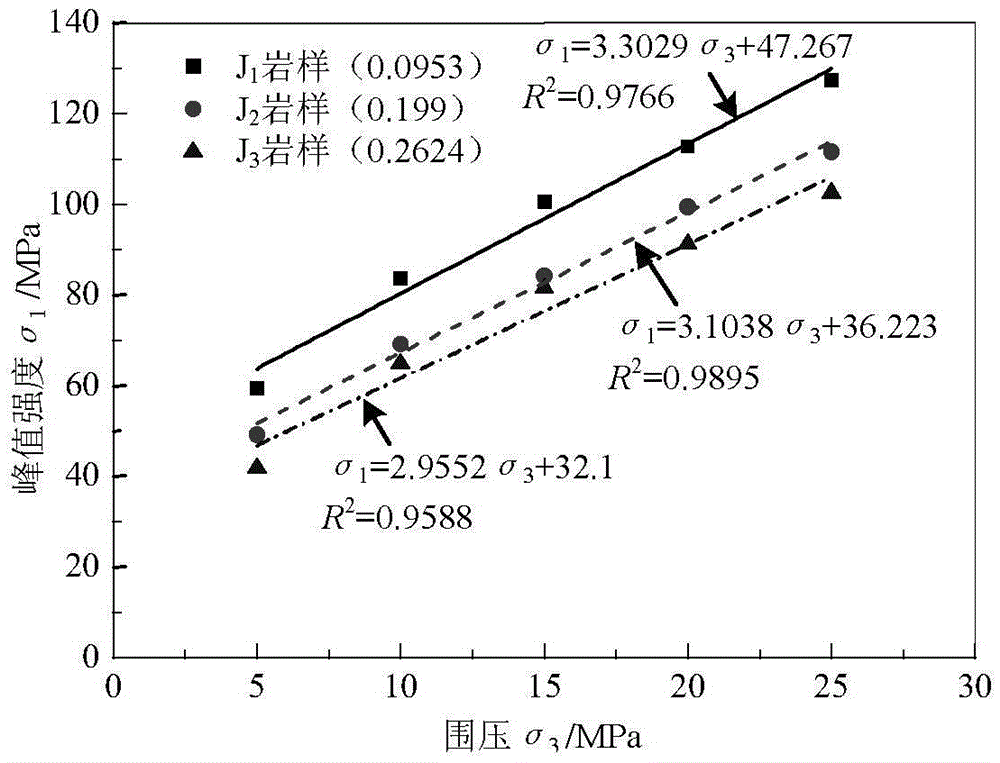

[0086] Perform uniaxial and triaxial compression tests on the rock samples to determine the peak strength σ of the rock samples 1 , Axial strain ε 1 and hoop strain ε 3 , fitting to get σ 1 and confining pressure σ 3 functional relationship, such as figure 2 shown. Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com