Metal welding test piece low temperature mechanical property optical test method

A technology for optical testing and metal welding, which is used in the application of stable tension/pressure to test the strength of materials, measuring devices, scientific instruments, etc. Avoid frosting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for testing the low-temperature mechanical properties of a metal welded test piece, comprising the following steps in sequence:

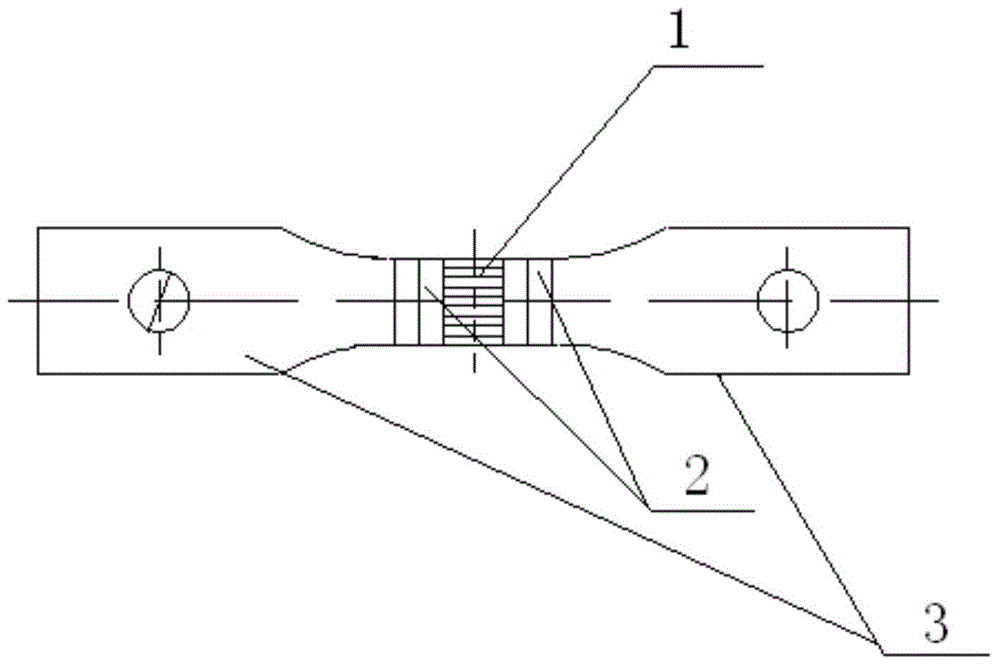

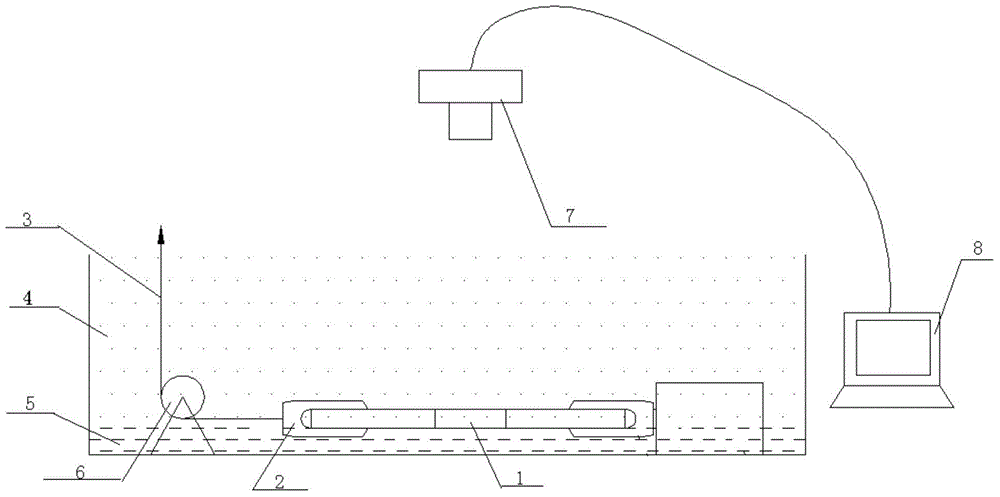

[0031] Step 1. Make welding test piece 1, butt-weld two metal material sheets to be tested to form a dumbbell-shaped standard tensile test piece, and divide welding test piece 1 into welding zone, heat-affected zone 1-2 and base metal zone 1 -3; In order to facilitate test identification, first spray white primer on the upper surface of welding test piece 1, and then spray black paint to form a speckle pattern, which is used to identify different positions of the test piece;

[0032] Step 2. Fix one end of the welding test piece 1, apply a load to the other end along the axial direction of the welding test piece 1, and then place the welding test piece 1 in an ultra-low temperature environment; the low temperature environment is formed by liquid nitrogen medium or other liquid that can provide a low temperature environment The medium...

Embodiment 2

[0043] In this embodiment, the research on the mechanical properties of the tank structure of the spacecraft is mainly carried out. Most spacecraft tank structures are welded, and the weak link of the structure usually lies in the welds. The mechanical properties of the welds determine the load-carrying capacity of the structure, so the research is mainly on the mechanical properties of the welds. Because the actual structure of the spacecraft storage tank is complex and the volume is large, the low-temperature test period for the storage tank entity is long, the cost is high, and the implementation is difficult. Therefore, the technical solution of the present invention uses welding test pieces to simulate the actual welding structure.

[0044] An optical test method for low-temperature mechanical properties of an aluminum alloy welded test piece, comprising the following steps in sequence:

[0045] Step 1. Make welding test piece 1, and use variable polarity argon arc weldin...

Embodiment 3

[0060] On the basis of Example 2, two metal sheets are welded by friction stir welding in step 1, and other steps are the same as in Example 2 to obtain the strain values of each area and the overall strain value J of the friction stir welding test piece 11, and obtain The relationship between the applied load and the strain value of the welded aluminum alloy welding test piece 11 is as follows: image 3 Shown; Calculate the engineering stress, test stress, strength limit and elongation of each region and the welding test piece 11 as a whole, and obtain the statistical results of the mechanical properties of the friction stir welding welding test piece 11 as shown in Table 2.

[0061] Table 2. Statistical statistics of mechanical properties of friction stir welding test pieces

[0062]

[0063] Such as Figure 4 As shown, when the load is between 0-26kN, the load-strain curve of the weld, that is, the heat-affected zone 1-2, is relatively straight, that is, the structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com