Anti-fog performance verifying device for car lamp design, and operating method therefor

A verification device and anti-fog technology, applied in measuring devices, testing of machine/structural components, instruments, etc., can solve problems such as affecting the service life and performance of surrounding parts, deteriorating lighting quality of lamps, hidden dangers of vehicle driving safety, etc. The effect of reducing the risk of fogging, reducing the risk of fogging, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

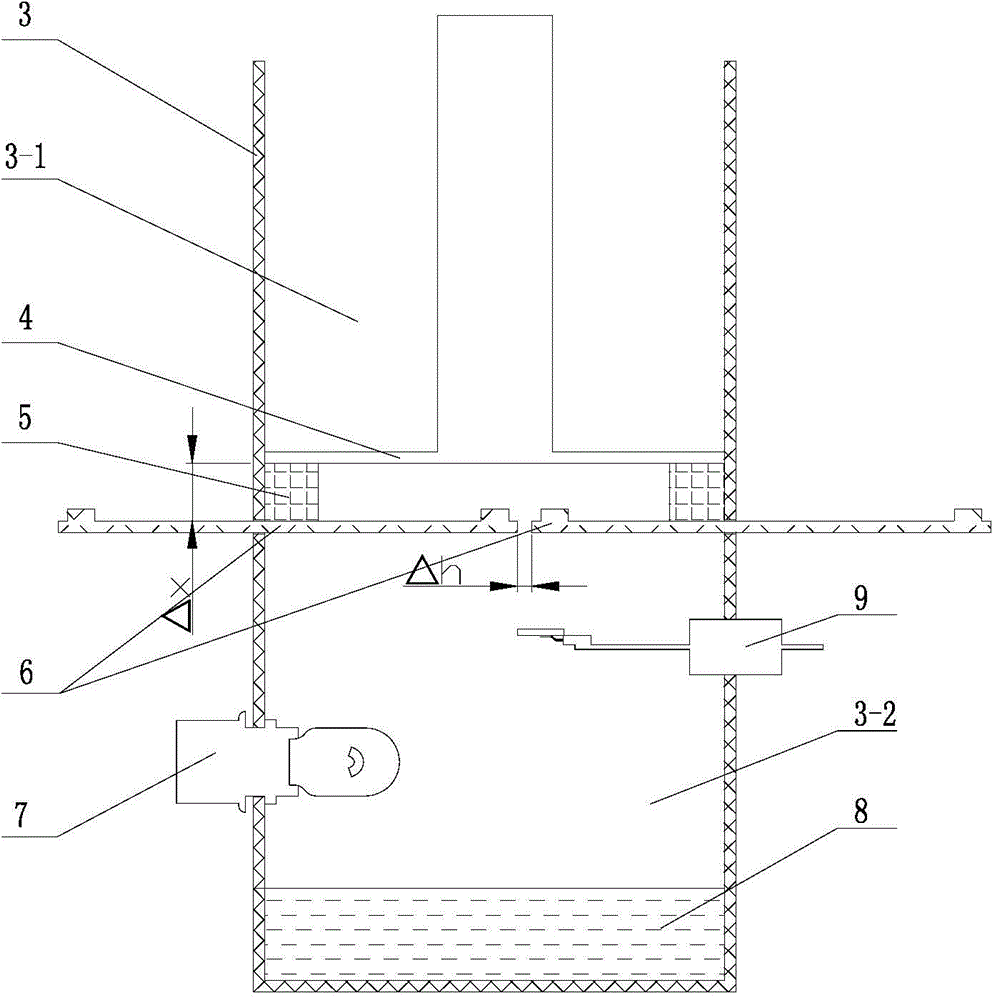

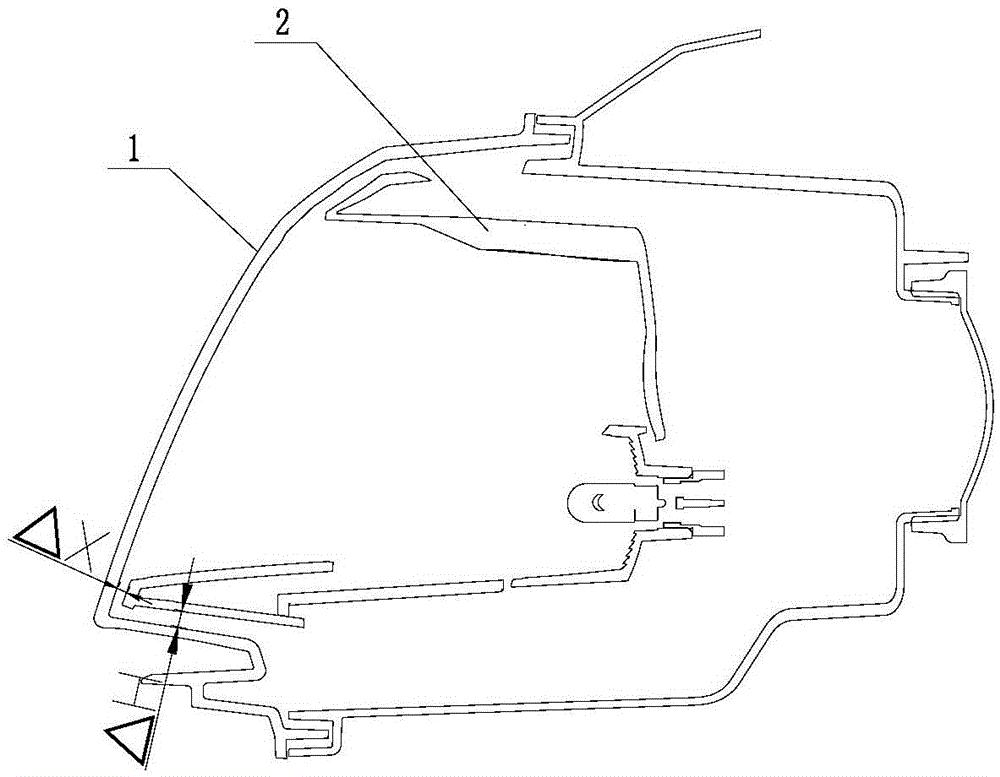

[0021] See figure 1 As shown, the verification device for the anti-fog performance of the car lamp design of the present invention includes a bulb 7, a lifting plate 4, two side slide plates 6, a humidity sensor 9 and a tank 3 for containing liquid 8. The bulb 7 of the present invention can be Choose any one of 5W, 16W, 21W, 35W or 55W.

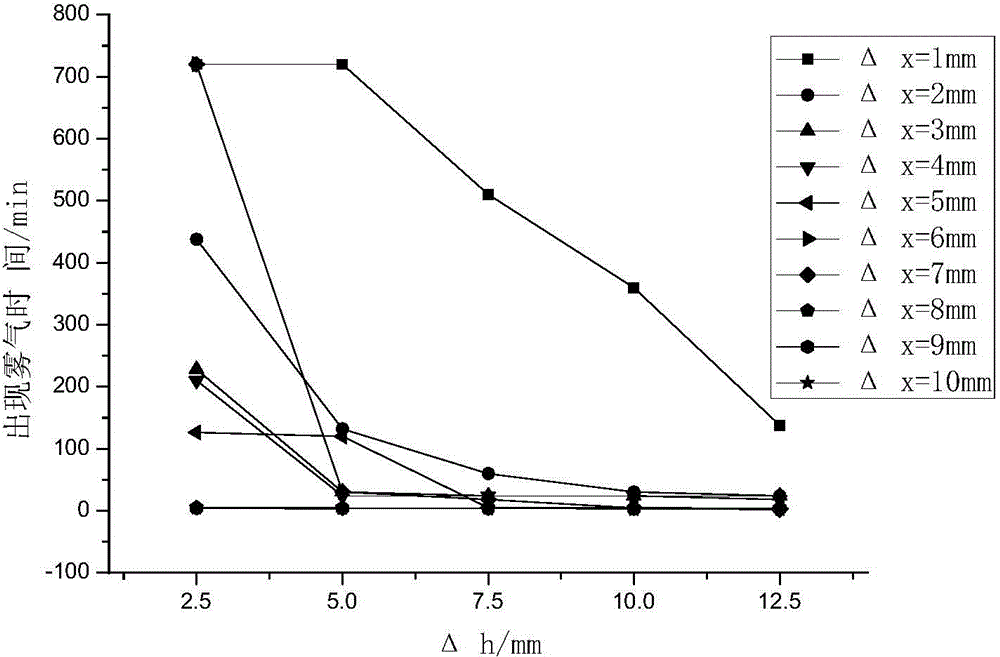

[0022] figure 1 As shown, two side slide plates 6 of the present invention are sealed and inserted on the groove wall of the tank body 3 and can move along the horizontal direction, and the two side slide plates 6 separate the tank body 3 into the high-humidity tank 3-2 and the high-humidity tank below. The liquid 8 contained in the upper low-humidity tank 3-1 and high-humidity tank 3-2 can use pure water as the source of moisture diffused to the low-humidity tank 3-1, and the water temperature is 20°C to 25°C. Two side slides There is an air-permeable interval △h between the 6 to control the diffusion of moisture in the high-humidity tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com