Structure and method for solving ice blockage problem of expansion main refrigerating machine evaporator

An evaporator and main refrigeration technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems affecting the normal operation of the production line, evaporator ice blockage, etc., and achieve the effect of reducing manual work intensity and downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

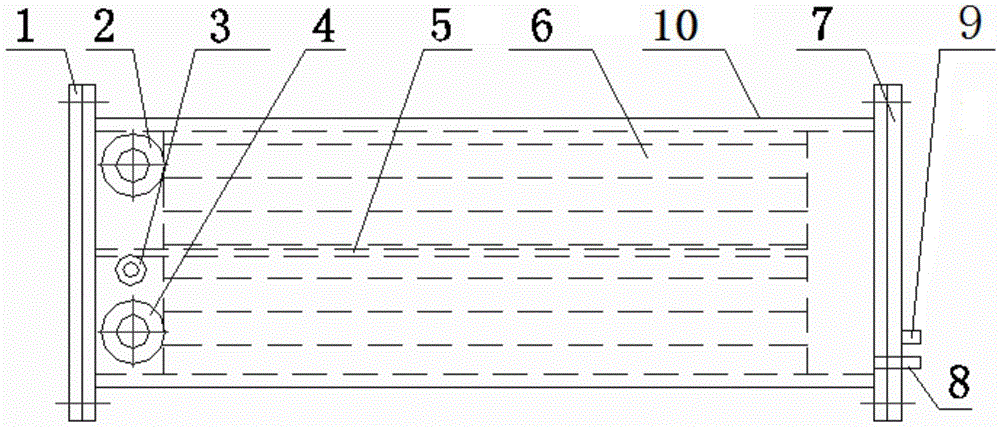

[0031] Example: such as figure 1 As shown, a structure for solving the ice blockage of the evaporator of the expansion main refrigerator includes an evaporator body 10, the east end of the evaporator body 10 is connected to the east flange 1 of the evaporator, and the west end is connected to the west flange 7 of the evaporator. The evaporator body 10 has a carbon dioxide inlet pipe 2 , a carbon dioxide liquid return pipe 4 and a plug installation port, and the evaporator body 10 has a condensing tube bundle 6 and a gas-liquid separator 5 inside.

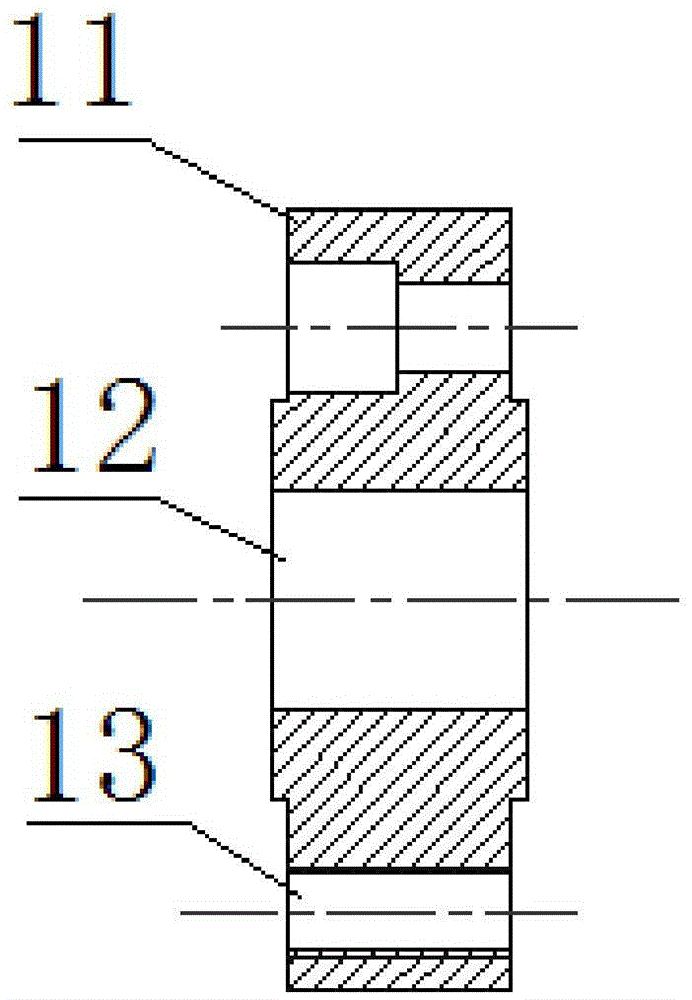

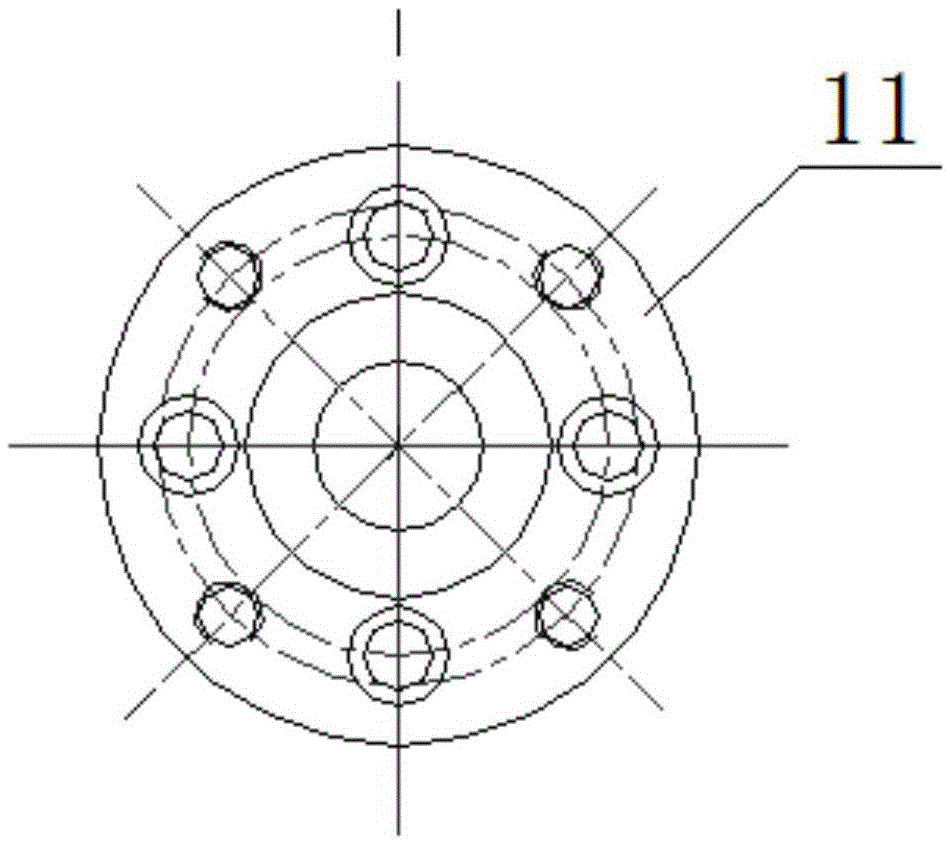

[0032] Next to the east flange 1 of the evaporator, an air inlet joint 3 is installed on the lower part of the evaporator body 10 . Such as figure 2 and image 3 As shown, the transition flange 11 has an air flow channel 12 in the center, and the outside of the air flow channel 13 has a stepped structure assembly hole 13 and a cylindrical structure assembly hole 13. replacement.

[0033] An air outlet valve 9 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com