Efficient strip cutting device for rubber sheets

A rubber sheet, high-efficiency technology, applied in the direction of metal processing, etc., can solve the problems of increasing labor intensity, inconvenience, fried edges and bulging of workers, and achieve the effect of avoiding curling and fried edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

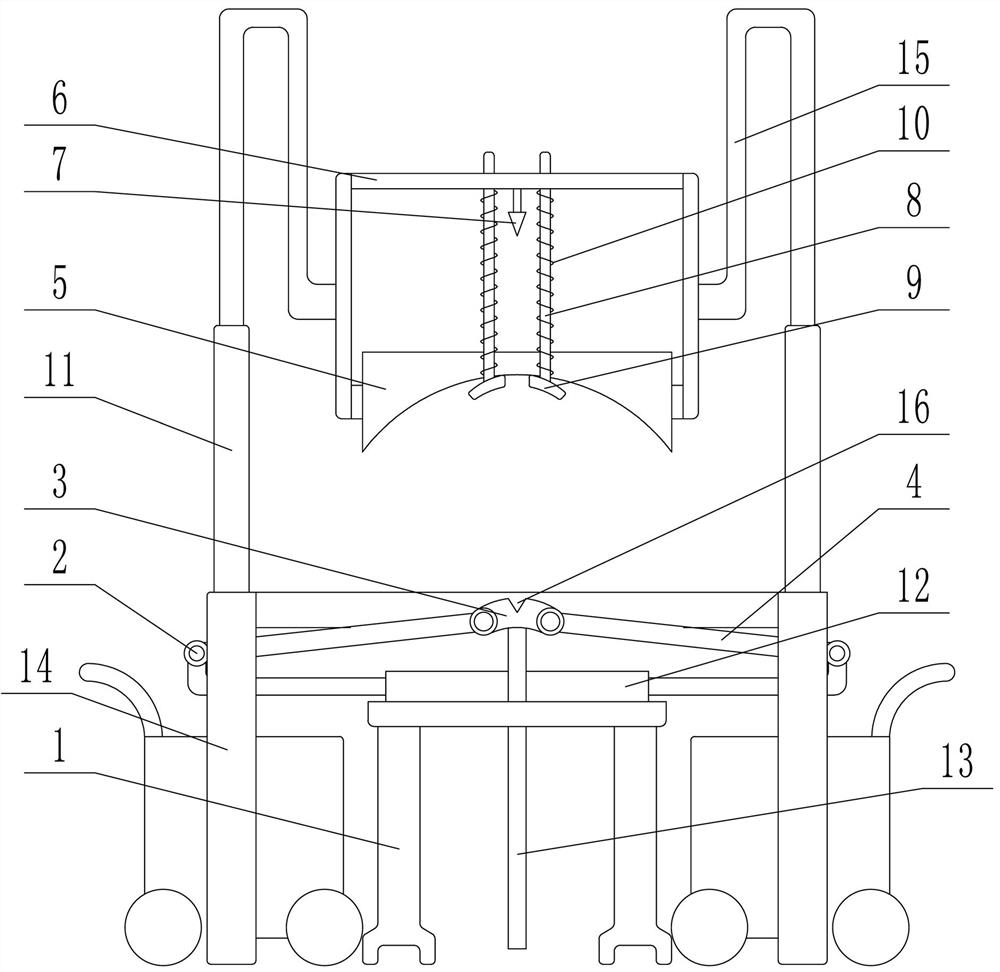

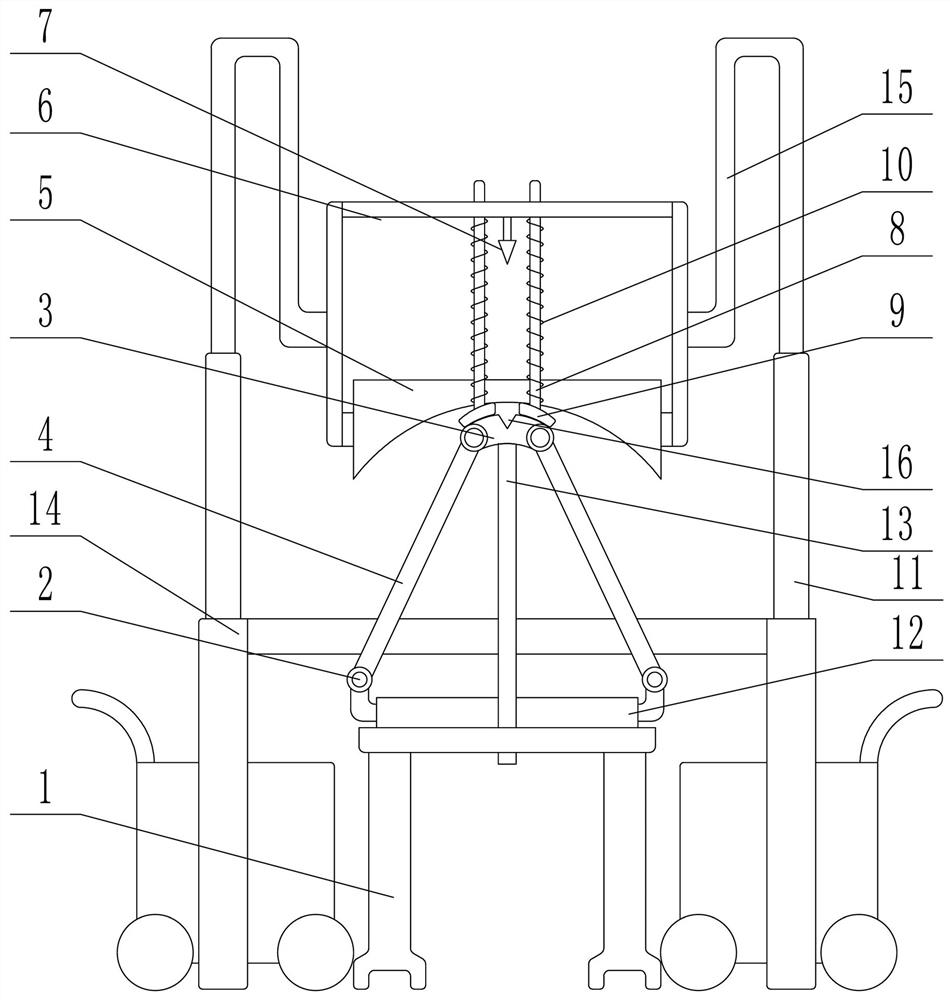

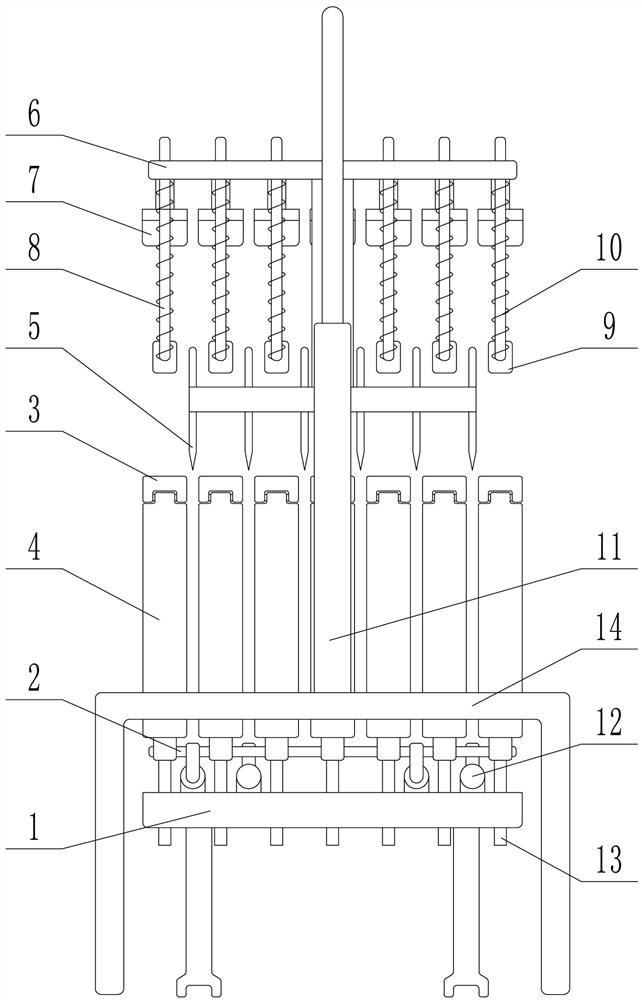

[0016] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Depend on Figure 1 to Figure 4 It can be seen that the present invention includes a base 1, and the left and right sides above the base 1 are respectively provided with a support rod 2 in the front and rear directions of the axis. The two support rods 2 can move in opposite directions synchronously. An arc-shaped support body 3, a connecting rod 4 is hinged on the left and right sides of each supporting body 3, and the other end of the connecting rod 4 is hinged on the supporting rod 2 on the corresponding side, and the supporting body 3 is connected with the connecting rods on both sides. 4. Form a support unit. When the support rod 2 moves closer to the middle, the support body 3 is jacked up. When the support rod 2 moves outward, the support body 3 is driven downward. A first Cutter 5, a plurality of first cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com