A self-cascading vapor compression refrigeration cycle system with gas-gas ejector synergies

A technology of vapor compression and circulation system, which is applied in the direction of compressors, refrigerators, compressors, etc. with cascade operation, which can solve the problems of insufficient separation of high and low boiling point components of refrigerants, and low energy efficiency of self-cascading refrigeration systems. , to achieve the effect of simple structure, promoting development and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

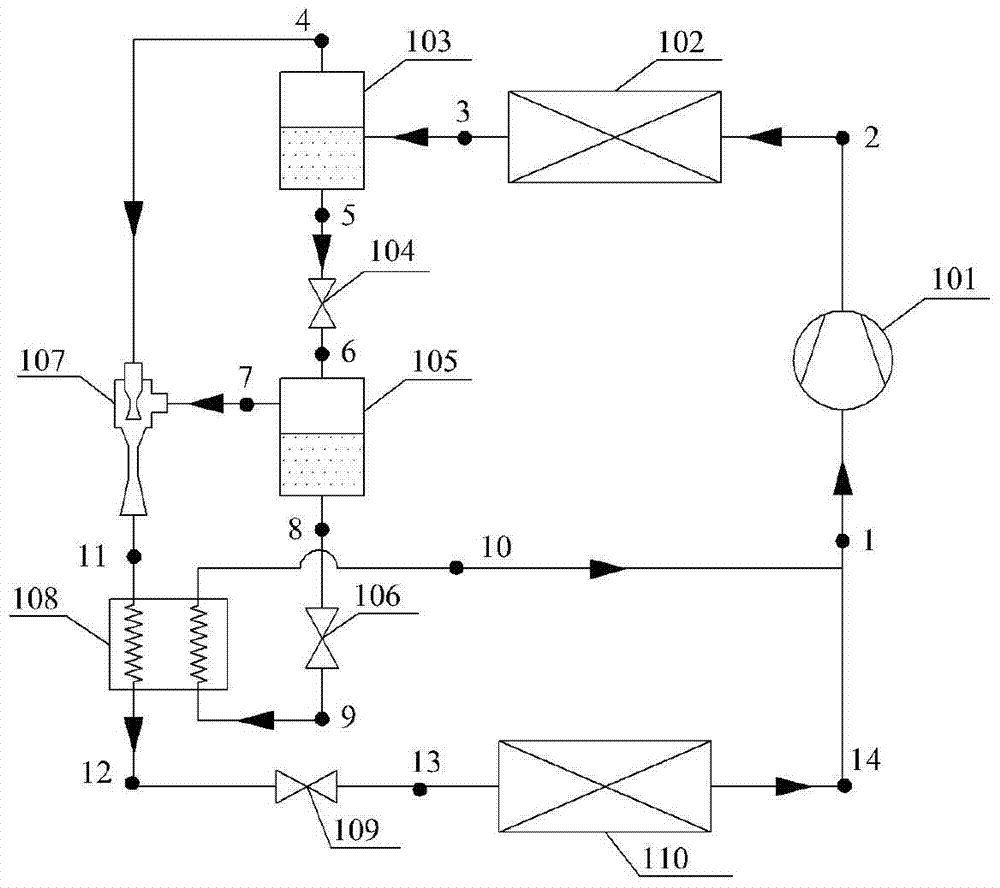

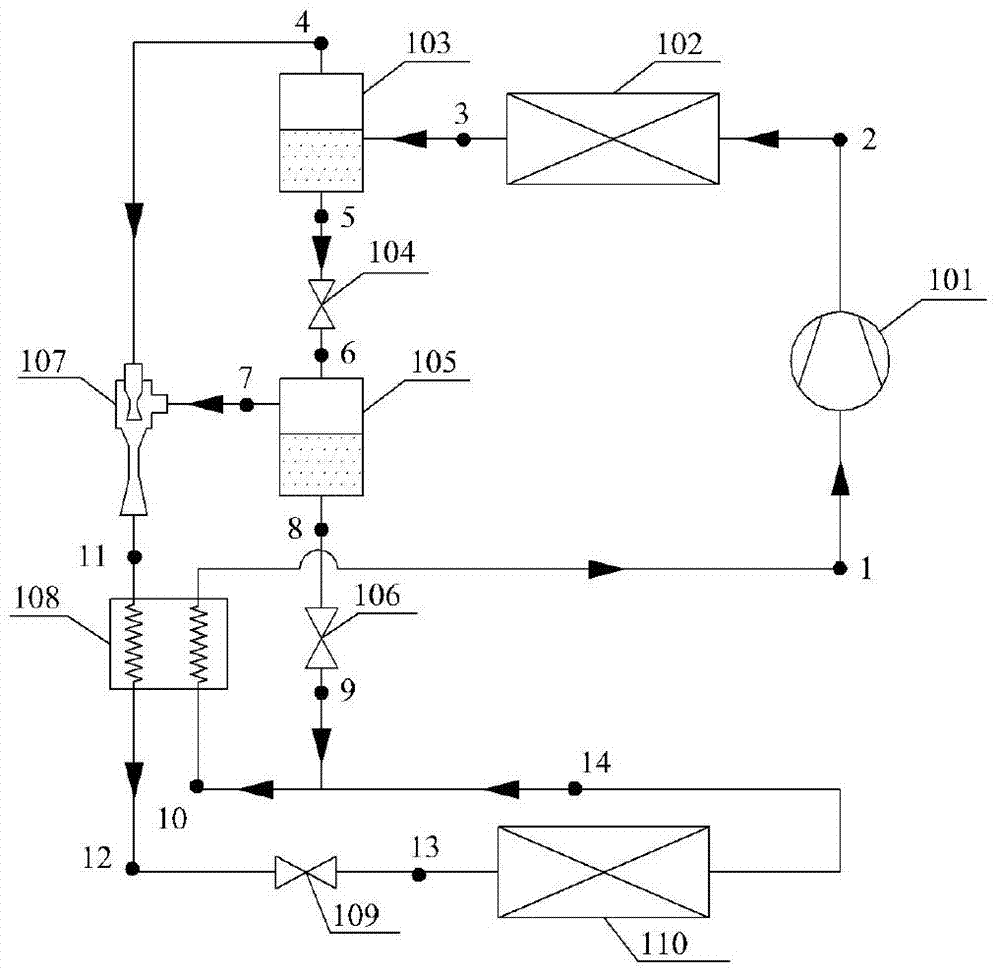

[0012] Such as figure 1 with figure 2 As shown, the present invention is a gas-gas ejector synergistic self-cascading vapor compression refrigeration cycle system, including a compressor 101, a condenser 102 and a first gas-liquid separator 103 connected in sequence, the first The outlet of the gas-liquid separator 103 is divided into two paths: one outlet of saturated refrigerant gas is connected to the working fluid inlet of the gas-gas ejector 107; the other outlet of saturated refrigerant liquid is connected to the inlet of the first throttling mechanism 104, the first section The outlet of the flow mechanism 104 is connected to the inlet of the second gas-liquid separator 105 . The outlet of the second gas-liquid separator 105 is also divided into two paths: one outlet of saturated refrigerant liquid is connected to the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com