Axis height adjustable gear box supporting structure

A technology of support structure and shaft height, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission box, etc. The problem of large deviation, etc., achieves the effect of flexible design of the centering reference, reducing the centering degree, reducing the turbulent flow space and blowing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The structure and technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings, and an embodiment will be given.

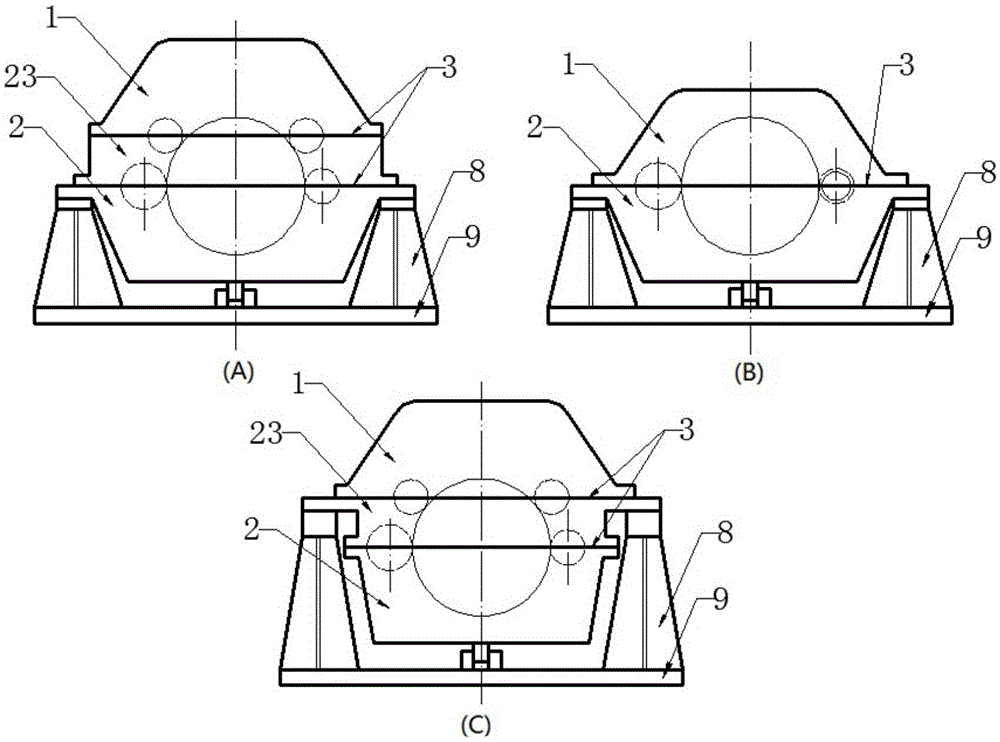

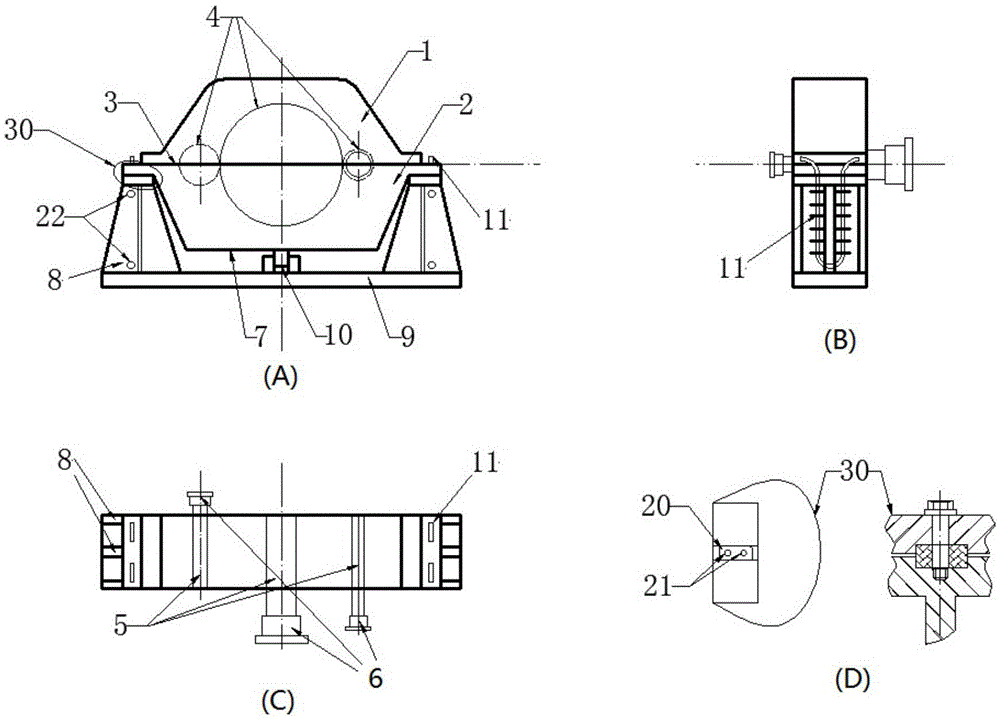

[0023] figure 1 Several typical gearbox structures are shown, among which, figure 1 (A) In the gear box support structure shown, the gear box includes an upper box body 1 and a lower box body 2, and a middle split surface 3 is formed on the contact surface between the gear box lower box body 2 and the gear box upper box body 1 , each stage of impeller machinery includes at least one transmission shaft, and each transmission shaft is arranged on the middle split plane 3 through bearings, and the gearbox is supported on the gear box bracket at a position near the middle split plane 3 . figure 1 The gear box structures shown in (B) and (C) respectively have two mid-section planes, the contact surface between the middle case m of the gear box and the upper case body 1 of the gear box forms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com