Reverse production method and production equipment for seafloor natural gas hydrate stable layer

A mining method and natural gas technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of inapplicable subsea natural gas hydrate stable layer, low replacement efficiency, natural gas environmental pollution, etc., and achieve reduction of atmospheric pollution. Effect of greenhouse effect, reduction of carbon dioxide content, and avoidance of direct emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

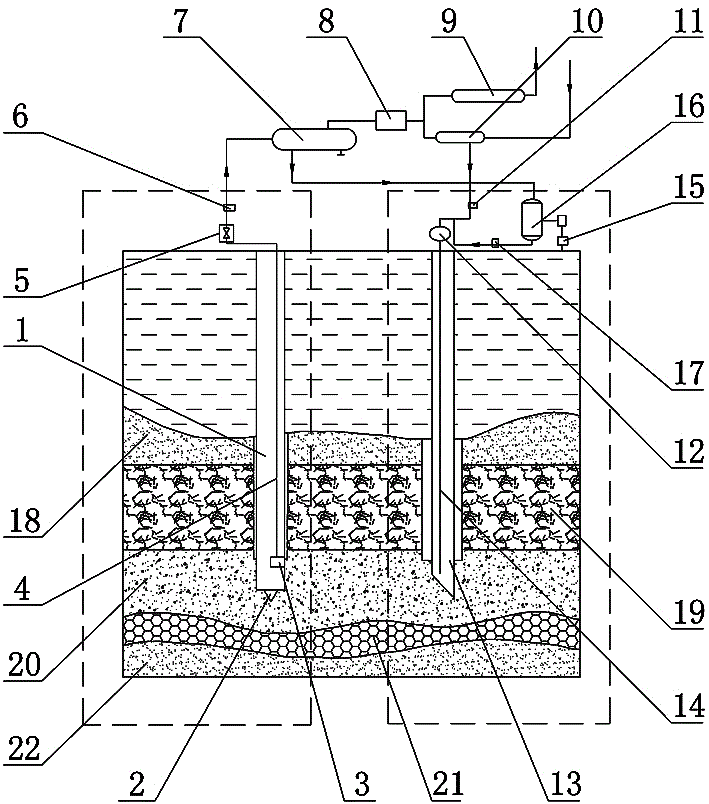

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0023] A method for reverse mining of a seabed natural gas hydrate stable layer, comprising the following steps:

[0024] S1. Depressurization gas production: drill a production well 1 to pass through the seabed sediment layer 18, the natural gas hydrate stable layer 19, and reach the production layer 20. Install a submersible pump 3 at the bottom of the production well 1, open the regulating valve A6, and start the descending process. The pressure gas recovery module uses the submersible pump 3 to extract the liquid in the production well 1, so that the pressure in the production well 1 is reduced, and the free gas under the natural gas hydrate stable layer 19 and the natural gas decomposed on the lower surface of the natural gas hydrate stable layer 19 are released on the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com