A rain downpipe with an inner helical structure

A technology of internal spiral and rain falling, which is applied in the direction of building structure, roof, roof covering, etc., to achieve significant economical practicality, reduce the probability of occurrence, and prolong the effect of exercise time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

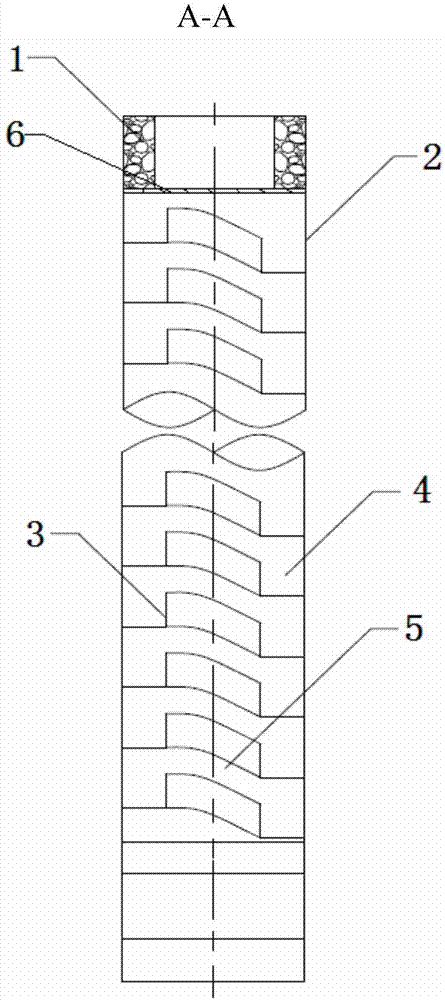

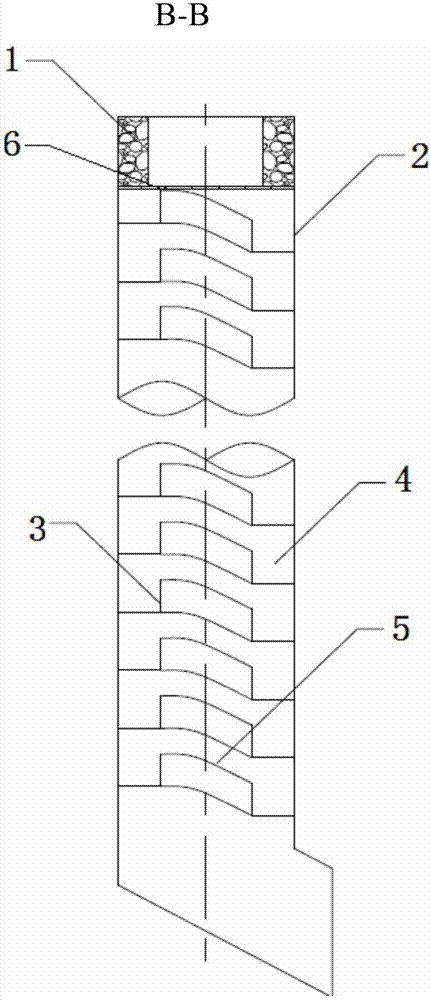

[0018] The overall length of the rain drop pipe is slightly smaller than the height of the building. The pipe body 2 is a metal pipe with a diameter of 20cm. The outer diameter of the inlet filter ring 1 is the same as the diameter of the pipe body 2. The inner diameter of the inlet filter ring 1 is 12cm, that is, the inlet filter ring The radial width of the ring 1 is 4cm; the radial width of the spiral slow-discharge channel 4 is 5cm, and the height of the spiral slow-discharge channel 4 (along the axial direction) is 6cm. The axial distance between corresponding points (that is, the pitch of the spiral slow-discharge channel 4 ) is 15 cm.

[0019] When rainfall is less intense, the roof produces less runoff. After the runoff is generated on the roof, the roof rainwater runoff first passes through the inlet filter ring 1 located at the top of the inner spiral rain downpipe, and then flows into the spiral slow discharge channel 4 after being filtered by the inlet filter ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com