Prefabricated ecological embankment plate for drainage ditch and manufacturing method of prefabricated ecological embankment plate

A drainage ditch and ecological technology, which is applied to the field of prefabricated ecological protective masonry for drainage ditch and its preparation, can solve the problems of no sewage filtration treatment, high requirements on slope environment, uneconomical reinforcement of reinforcement, etc., and avoid slab paving. Uneven, preventing planting soil from scattering, good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

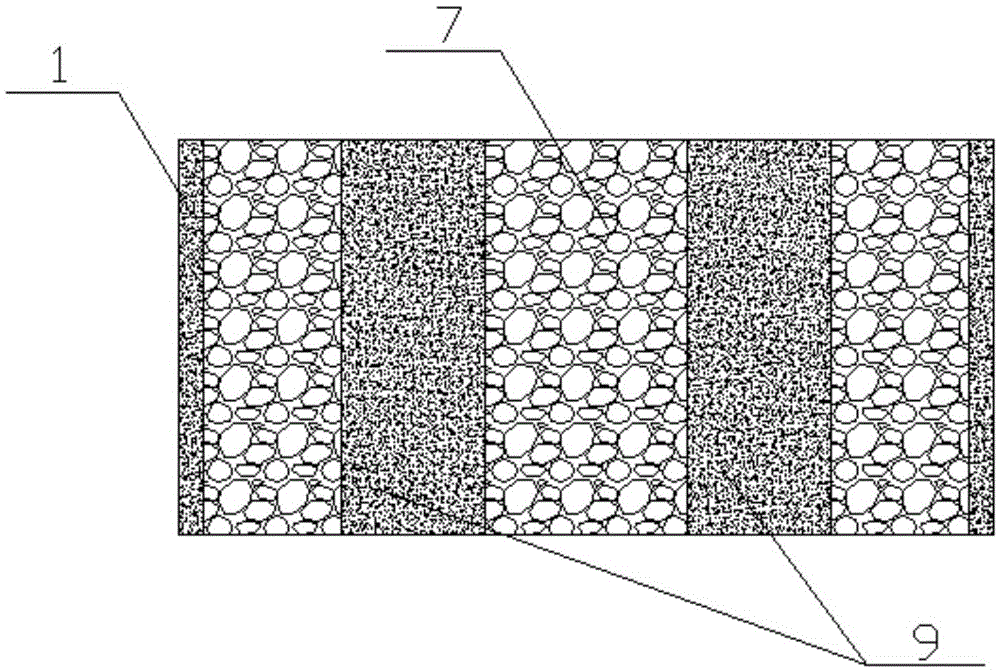

[0014] combine figure 1 , figure 2 and image 3 , the prefabricated ecological protective panel for the drainage ditch of the present invention, including RPC box 1, restraint rope 3, planting bag 4, permeable concrete layer 7, filter bag 8, reverse filter bag 6, RPC box 1 is a thin shell side wall and bottom The bottom of the RPC box 1 is composed of a filter bag 8, a permeable concrete layer 7, and a vegetation bag 4 from bottom to top, and an anti-filter bag 6 is attached to the outside of the bottom of the RPC box 1, and the tie rope 3 passes through it. The fixing hole 5 on the side wall of the RPC box 1 fixes the vegetation bag 4, the permeable concrete layer 7, the dirt filter bag 8, and the reverse filter bag 6 inside and outside the RPC box 1.

[0015] The preparation method of the prefabricated ecological protective panel for drainage ditch of the present invention, the steps are as follows:

[0016] (1) Utilize the RPC material (RPC refers to active powder concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com