Rare earth molten salt electrolytic cell with novel electrode structure

An electrode structure, molten salt electrolysis technology, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problems of uneven distribution of electric heating field, unstable electrolysis production process, etc., to improve electrolysis current efficiency, easy industrial processing, electric heating The effect of uniform field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

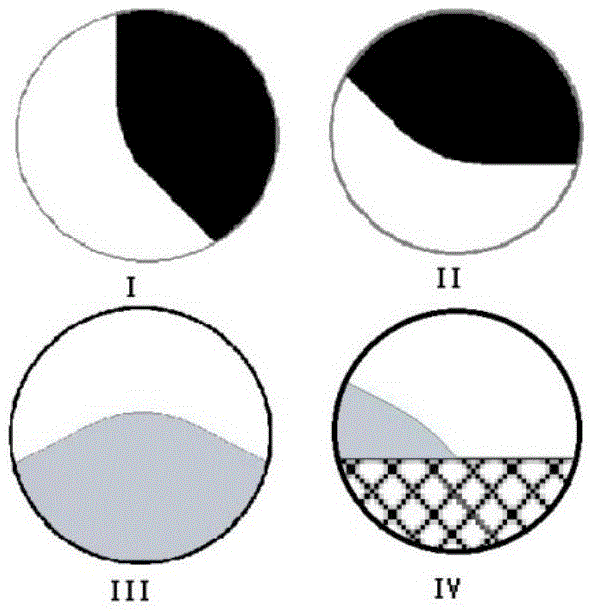

[0021] See figure 1 , figure 2 , image 3 , Figure 4 This embodiment is provided with two rows of anodes and two rows of cathodes. The bottom surface of the anode is "V" shaped. Each anode is composed of two anode blocks. The bottom surfaces of the two anodes enclose an inverted "V"-shaped inclined surface, and two The distance between the anodes is 10mm, all sharp corners at the bottom of the anode are chamfered, and the chamfering radius is 30mm. The top of the cathode is in the shape of a triangular prism. The upper part of each cathode corresponds to the middle of two anodes surrounded by an inverted "V" shape. The entire cathode is composed of a triangular prism at the top and a rectangular parallelepiped below it. All sharp corners are chamfered, and the chamfering radius is 10mm. In this embodiment, one anode is composed of two anode blocks, and a gap is left between the two anode blocks, so that the bubbles at the bottom of the anode can be quickly discharged. In thi...

Embodiment 2

[0023] See Figure 5 In this embodiment, each row of anodes is composed of four anode blocks. The two anode blocks in the middle part of each row of anode blocks are inverted trapezoid, and at the beginning and the end are inclined blocks that match the adjacent middle parts. All the anode blocks are surrounded by three anodes with an inverted “V”-shaped bottom surface, and the distance between the two anodes is 20mm. All sharp corners at the bottom of the anode are chamfered, and the chamfering radius is 50mm . The top of the cathode is in the shape of a triangular prism. The upper part of each cathode corresponds to the middle of two anodes surrounded by an inverted "V" shape. The entire cathode is composed of a triangular prism at the top and a rectangular parallelepiped below it. All sharp corners are chamfered, and the chamfering radius is 20mm. The gap between the two anode blocks allows the bubbles at the bottom of the anode to be quickly discharged. In this embodimen...

Embodiment 3

[0025] In this embodiment, a cathode is placed below the anode. The bottom surface of the anode is in a "V" shape. Each group of anodes is composed of two anode blocks. The bottom surfaces of the two anodes form an inverted "V"-shaped slope, and the distance between the two anodes is 30mm, all sharp corners at the bottom of the anode are chamfered, and the chamfer radius is 80mm. The top of the cathode is in the shape of a triangular prism. The upper part of each cathode corresponds to the middle of two anodes surrounded by an inverted "V" shape. The entire cathode is composed of a triangular prism at the top and a rectangular parallelepiped below it. All sharp corners are chamfered, and the chamfer radius is 30mm. In this embodiment, one anode is composed of two anode blocks, and a gap is left between the two anode blocks, so that the bubbles at the bottom of the anode can be quickly discharged. In this embodiment, there are a total of 6 groups of anodes and 6 corresponding g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com