Preparation method and application of 7-aminocephalosporanic acid

A technology of aminocephalosporanic acid and cephalosporins, which is applied in the direction of fermentation, etc., can solve the problems of reduced reaction speed of immobilized enzymes, and achieve the effects of improving catalytic stability, shortening catalytic time, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The present invention is described in more detail below by way of examples. However, the scope of the present invention is not limited to the examples.

[0033] Analytical method in the embodiment:

[0034] (1) Establish the standard curve of product 7-ACA :

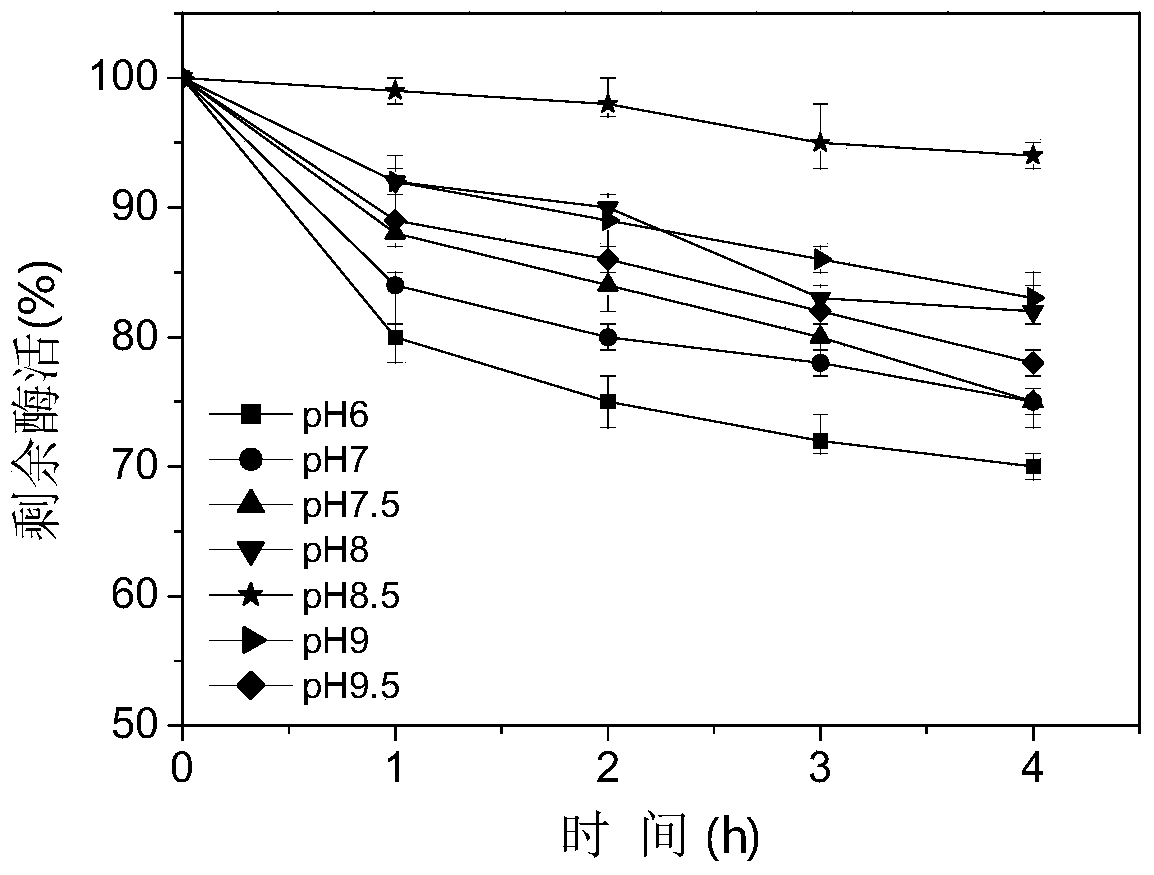

[0035] 1) Prepare 20mg / mL CPC solution and 3mg / mL 7-ACA solution with 0.1mol / L, pH8.5 sodium phosphate buffer solution, and adjust the pH to 8.5 with 1mol / L NaOH solution.

[0036] 2) Add 0, 1, 2, 4, 8, 12, 16, and 20 μL of 7-ACA solution into centrifuge tubes, and make up to 20 μL with 0.1 mol / L sodium phosphate buffer solution at pH 8.5 one by one.

[0037] 3) Add 20 μL of CPC solution (preheated at 37°C for 3 minutes) to each tube and mix well, let stand at 37°C for 5 minutes, then add 200 μL of stop solution (50 mmol / L NaOH solution and 20% glacial acetic acid solution at a ratio of 1:2 volume ratio), and shake well to mix.

[0038] 4) Centrifuge the above mixed solution at 12000rpm for 3min, then take 200...

Embodiment 1

[0060] Preparation of immobilized CPC acylase: Add CPC acylase and 1.25M sodium phosphate buffer (pH8.0) twice the volume of enzyme solution to about 20 g of EPC carrier, so that the final concentration of sodium phosphate buffer is 0.83M. Under the condition of 25°C and 160rpm, let it stand for 24h. After 24 hours, the carrier was washed with deionized water and 0.1M PBS, recovered by suction filtration and stored at 4°C. And use the aforementioned method to measure the enzyme activity.

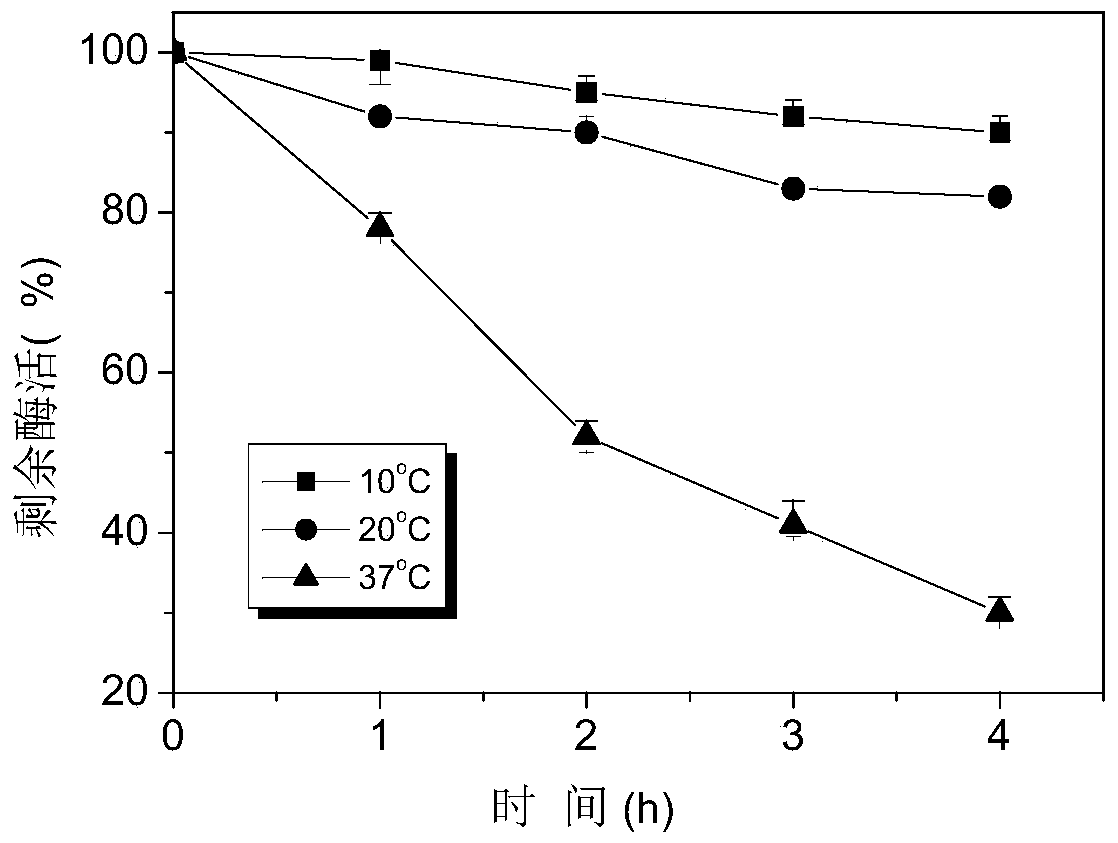

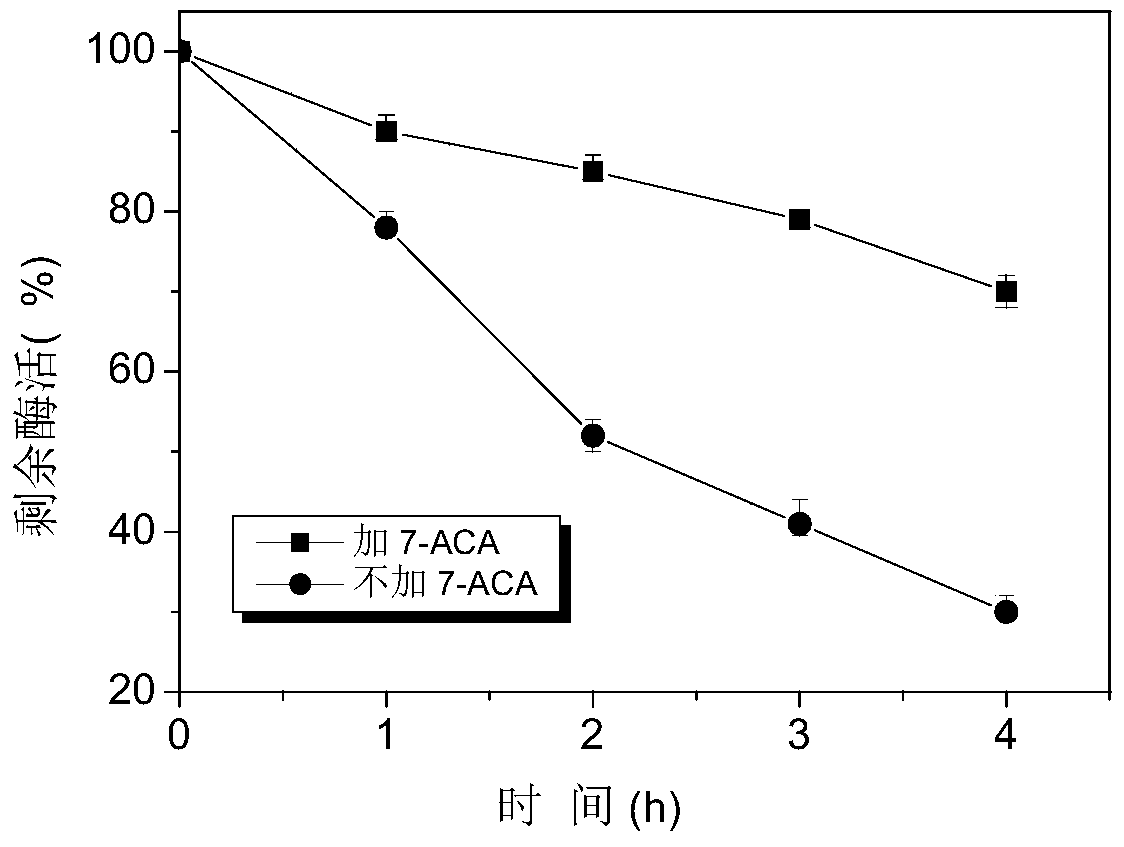

[0061] Catalytic reaction: The immobilized enzyme that obtains in the step (1) adopts the enzyme dosage of 6U / ml, drops in the cephalosporin C aqueous solution of 25mg / ml, and regulates reaction system pH8.5 with 2M ammonia water, is 10 with circulating water control reaction temperature. °C was maintained for 30 minutes, and then the reaction temperature was controlled at 37 °C until the end of the reaction.

[0062] During the whole reaction process, regular samples were taken to mea...

Embodiment 2-6

[0065] Examples 2-6 were carried out as described in Example 1, except for the temperature profile as follows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com