Low rolling resistance tire rubber material with ultrahigh wear resistance and synthetic method thereof

A technology with low rolling resistance and wear resistance, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve the problems of non-wear-resistant rubber, reduce tire rolling resistance, poor wet skid resistance, etc., and achieve good wet grip Ground strength, ultra-high wear resistance, better wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Raw material components: 95.94 parts of low-temperature emulsion polymer oil-extended styrene-butadiene rubber SBR1723, 17.5 parts of low-temperature emulsion polymer oil-extended styrene-butadiene rubber SBR1739, 17.5 parts of butadiene rubber BR9000, 40 parts of N234 carbon black, 40 parts of high-dispersion white carbon black, 3 1 part Coumarone resin COUMARONERESINCY-CR1 tackifying resin, 6 parts softening tackifier GOYENCHEM-GR80 tackifying resin, 4 parts antioxidant (2.5 parts 6PPD, 1.5 parts 3100), 2 parts vulcanizing agent, 6.4 parts coupling agent X -50S, 3.5 parts active agent (2.5 parts ZNO, 1 part SA), 2.6 parts accelerator (2.15 parts NS, 0.45 parts DPG).

[0035] Preparation process: (this process is carried out in a 270L internal mixer)

[0036] The first step: put in low-temperature emulsion poly oil-extended styrene-butadiene rubber 1723, low-temperature emulsion poly-oil-extended styrene-butadiene rubber 1739, butadiene rubber BR9000, N234 carbon black...

Embodiment 2

[0045] Raw material components: 88.44 parts of low-temperature emulsion poly oil-extended styrene-butadiene rubber SBR1723, 25 parts of low-temperature emulsion poly-oil-extended styrene-butadiene rubber SBR1739, 17.5 parts of butadiene rubber BR9000, 44 parts of N234 carbon black, 44 parts of high-dispersion white carbon black, 6 Parts Coumarone resin COUMARONERESINCY-CR1 tackifying resin, 8 parts softening tackifier GOYENCHEM-GR80 tackifying resin, 5 parts anti-aging agent (2.5 parts 6PPD, 2.5 parts 3100), 2 parts vulcanizing agent, 7.4 parts coupling agent X -50S, 4.5 parts active agent (2.5 parts ZNO, 2 parts SA), 2.6 parts accelerator (2.15 parts NS, 0.45 parts DPG).

[0046] Synthetic method is the same as embodiment 1.

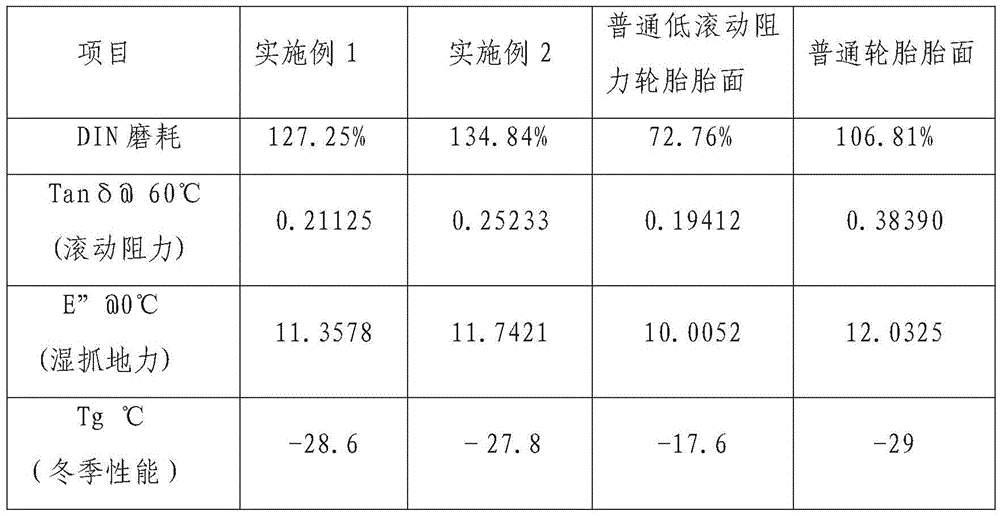

[0047] The ultra-high-performance tire compound is thus obtained, and the relevant parameters are shown in Table 1. The final tire product can reach a high speed of 255Km / h and a rolling resistance of A grade.

[0048] Table 1 The main technical indica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com