Preparation method of hydrophobic nano cellulose aerogel

A technology of nanocellulose and airgel, which is applied in the field of preparation of hydrophobic nanocellulose airgel, can solve the problems of long preparation period, complex process and expensive price, and achieve good hydrophobicity, simple equipment and process requirements, The effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Mix 200g of rod-shaped nano-microcrystalline cellulose hydrosol (6% solid content) with 200g of deionized water at room temperature to obtain a diluted hydrosol of nano-microcrystalline cellulose;

[0033] (2) adding 4 g of ammonium zirconium carbonate to the diluted hydrosol obtained in step (1) to obtain a mixed solution;

[0034] (3) Mix 40g of dimethyldiethoxysilane and 800g of n-hexane evenly, add to the mixed solution in step (2), heat and stir at 50°C for reaction, and the reaction time is 2.5h;

[0035] (4) After the reaction, the solution is separated and the water layer is removed to obtain a cellulose wet gel;

[0036] (5) The cellulose wet gel was dried at 100°C for 2 hours to obtain a hydrophobic nano-cellulose airgel.

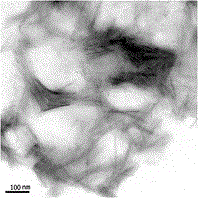

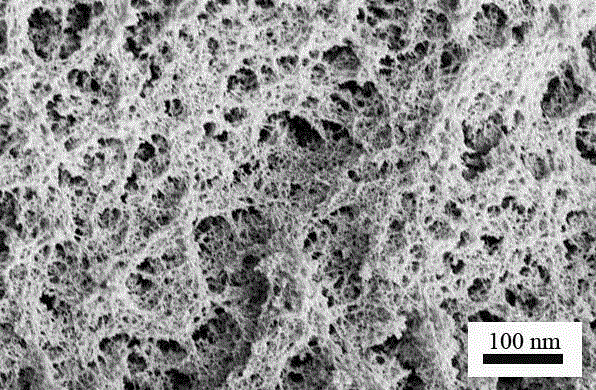

[0037] figure 1 It is a transmission electron microscope picture of rod-like nanocrystalline cellulose. by attaching figure 2 It can be seen that the prepared hydrophobic nanocellulose airgel has excellent hydrophobic properties, a...

Embodiment 2

[0043] (1) Mix 100g of rod-shaped nano-microcrystalline cellulose hydrosol (8% solid content) with 500g of deionized water at room temperature to obtain a diluted hydrosol of nano-microcrystalline cellulose;

[0044] (2) Add 0.6g of 2D resin to the diluted hydrosol obtained in step (1) to obtain a mixed solution;

[0045] (3) Mix 120g of methyltriethoxysilane and 120g of n-hexane and n-heptane mixed solution evenly, add to the mixed solution of step (2), heat and stir at 30°C for reaction, and the reaction time is 1.5h;

[0046] (4) After the reaction, the solution is separated and the water layer is removed to obtain a cellulose wet gel;

[0047] (5) The cellulose wet gel was dried at 180°C for 1 hour to obtain hydrophobic nanocellulose airgel.

[0048] Test Results:

[0049] Density: 0.05g / cm 3 ;

[0050] Specific surface area: 800m 2 / g;

[0051] Thermal conductivity: 0.022W / mK.

Embodiment 3

[0053] (1) Mix 100g spherical nano-microcrystalline cellulose hydrosol (10% solid content) with 300g deionized water at room temperature to obtain a diluted hydrosol of nano-microcrystalline cellulose;

[0054] (2) Add 12g of ammonium zirconium carbonate to the diluted hydrosol obtained in step (1) to obtain a mixed solution;

[0055] (3) Mix 40g of dimethyldimethoxysilane and 120g of n-heptane evenly, add to the mixed solution in step (2), heat and stir at 70°C for a reaction time of 0.5h;

[0056] (4) After the reaction, the solution is separated and the water layer is removed to obtain a cellulose wet gel;

[0057] (5) The cellulose wet gel was dried at 80°C for 6 hours to obtain a hydrophobic nano-cellulose aerogel.

[0058]Test Results:

[0059] Density: 0.2g / cm 3 ;

[0060] Specific surface area: 600m 2 / g;

[0061] Thermal conductivity: 0.04W / mK.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com