A kind of preparation method of high-purity alumina

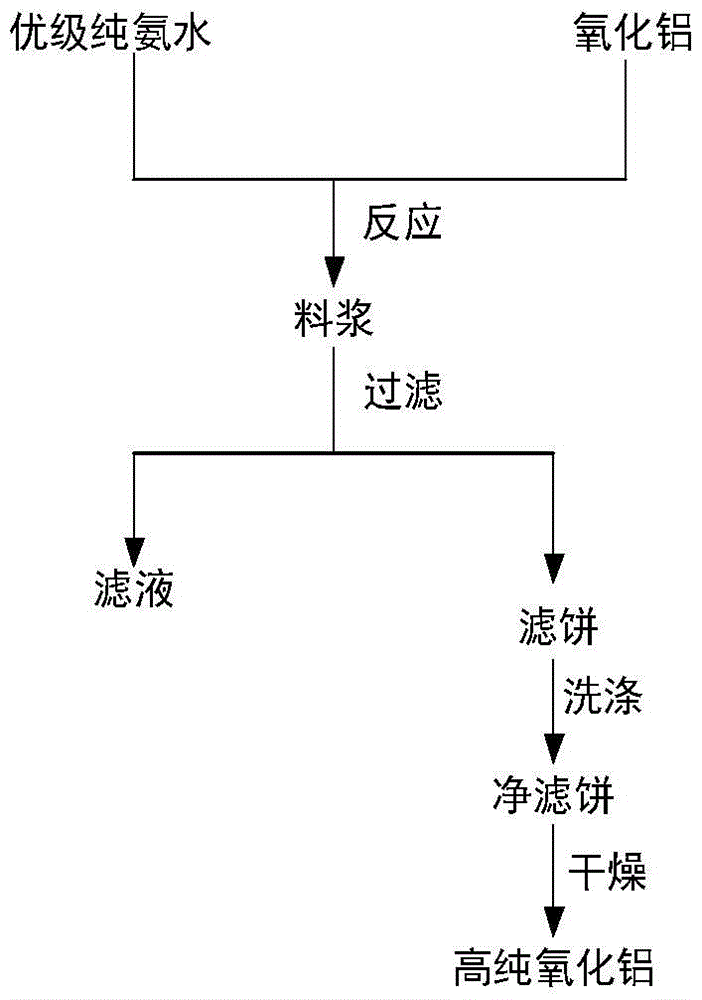

A technology of high-purity alumina and alumina, which is applied in the purification of aluminate/alumina/hydroxide, etc., can solve problems such as complex process flow, serious environmental pollution, and high production hazards, and achieve broad process conditions and high process efficiency. Simple process and high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The raw materials of this embodiment are aluminum oxide with a purity of 99.991% and superior pure ammonia water with a concentration of 8%. Mix the above aluminum oxide and ammonia water according to the ratio of L / S (mL / g) to 18, and mix them evenly Put the slurry into a clean reaction kettle, slowly raise the temperature to 250°C, and keep it warm at 250°C for 7 hours. After the reaction, the slurry is separated from liquid to solid, and the obtained filter cake is washed 5 times with 80°C high-purity water according to the water-solid ratio of 15. Drying at ℃, the purity of the obtained product is 99.9993%.

Embodiment 2

[0029] The raw materials of this embodiment are alumina with a purity of 99.995% and superior pure ammonia water with a concentration of 3%. Mix the above alumina and ammonia water according to the ratio of L / S (mL / g) to 30, and mix them evenly Put the slurry into a clean reaction kettle, raise the temperature slowly to 200°C, and keep it warm at 200°C for 9 hours. After the reaction, the slurry is separated from liquid to solid. Drying at ℃, the purity of the obtained product is 99.9992%.

Embodiment 3

[0031] The raw materials of this embodiment are aluminum oxide with a purity of 99.95% and superior pure ammonia water with a concentration of 9%. Mix the above aluminum oxide and ammonia water according to the ratio of L / S (mL / g) to 40, and mix them evenly Put the slurry into a clean reaction kettle, slowly raise the temperature to 230°C, and keep it warm at 230°C for 20 hours. After the reaction, the slurry is separated from liquid to solid, and the obtained filter cake is washed 5 times with 95°C high-purity water according to the water-solid ratio of 15. Drying at ℃, the purity of the obtained product is 99.9991%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com