MEMS release auxiliary structure and preparation method thereof

A technology of auxiliary structure and structural layer, applied in the field of MEMS release auxiliary structure and its preparation, can solve the problems of diffraction effect, adverse effect on device performance, reduce device reflection coefficient, etc., achieve complete process compatibility, easy industrial value, and shorten the release length. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

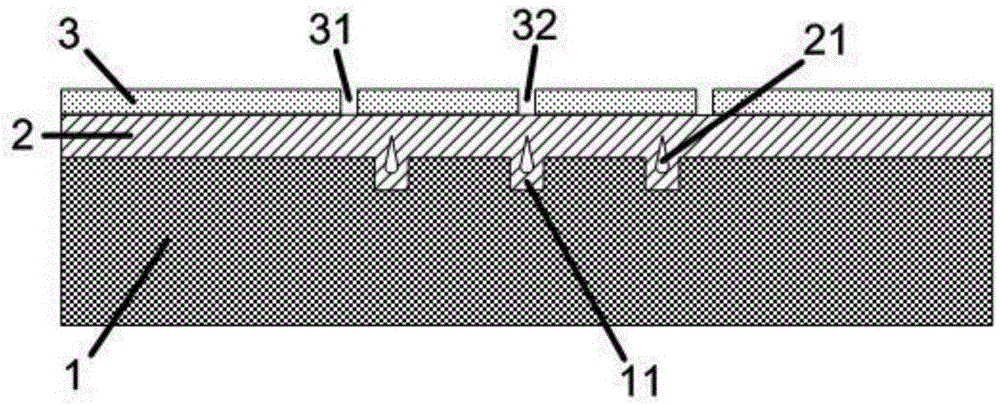

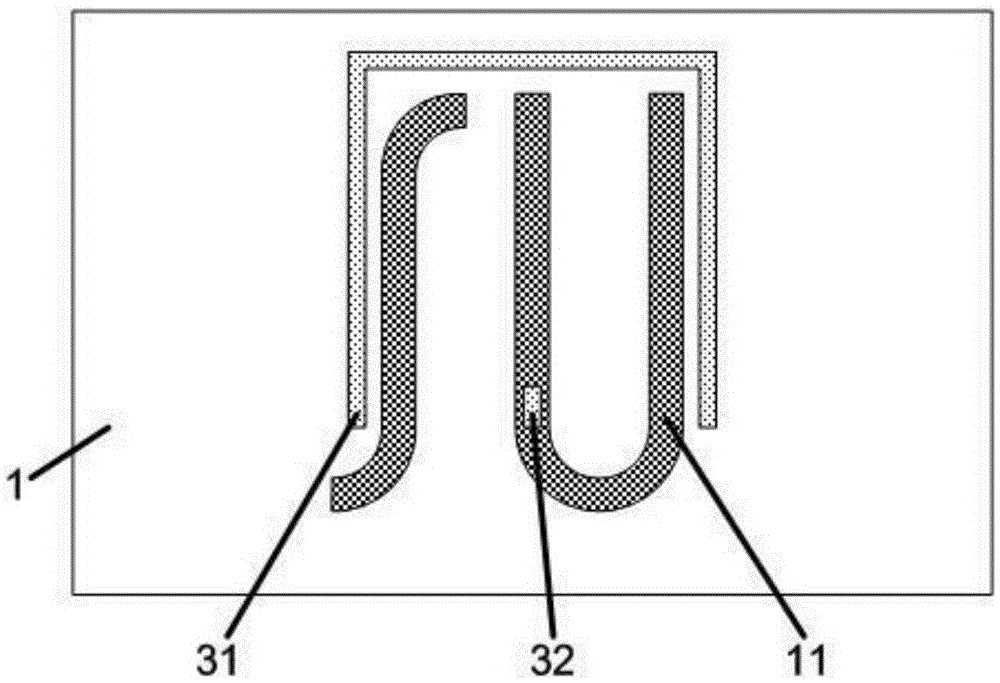

[0031] Such as Figure 1-2 , a MEMS release auxiliary structure, including a bottom layer, and a second sacrificial layer 2 and a second structural layer 3 arranged on the bottom layer in sequence, three grooves are arranged on the side of the bottom layer near the second sacrificial layer 2, and the second sacrificial layer 2 extend into the grooves, and form cavities 21 in each corresponding groove, and the air pressure in the cavities 21 is lower than the air pressure in the corrosive environment. Each of the etchant inlets is one of the etchant inlets, one of the etchant inlets is specifically the structural layer through-hole, and the other of the etchant inlet is specifically the release auxiliary hole 32. The through hole in the structural layer is more specifically the boundary opening 31 in this embodiment.

[0032] Here, the design of the release auxiliary hole 32 is an icing on the cake in terms of shortening the release length for devices with boundary openings 31...

Embodiment 2

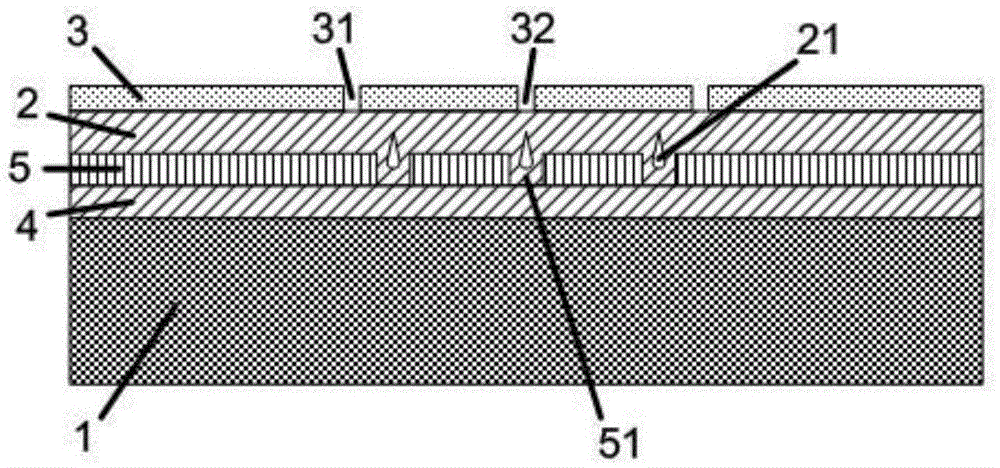

[0041] Such as image 3 , a MEMS release auxiliary structure, the difference from Embodiment 1 is that the bottom layer is formed by sequentially forming a first sacrificial layer 4 and a first structure layer 5 on a substrate 1 . The first sacrificial layer 4 is silicon oxide, and the first structural layer 5 is polysilicon.

[0042] The difference between the preparation method of the MEMS release auxiliary structure of this embodiment and the preparation method of Example 1 is:

[0043] Before step (1), first deposit silicon oxide on the substrate 1 to form the first sacrificial layer 4, then deposit polysilicon on the first sacrificial layer 4 to form the first structural layer 5, thereby forming the bottom layer, and in step (1) on the bottom layer The groove is specifically composed of a through hole 51 etched on the first structure layer 5 .

[0044] The working principle of the MEMS release auxiliary structure in this embodiment is the same as that in Embodiment 1. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com