Heart ventricular septal defect plugging device with two flat end faces and manufacturing method of heart ventricular septal defect plugging device

A technology for ventricular septal defect and occluder, which is applied in medical science, surgery, etc., can solve the problems of slow endothelialization, high cost, and long release length of the occluder, and achieves reduced damage, low manufacturing cost, and reduced release length. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0153] The present invention will be further described by means of embodiments below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the embodiments.

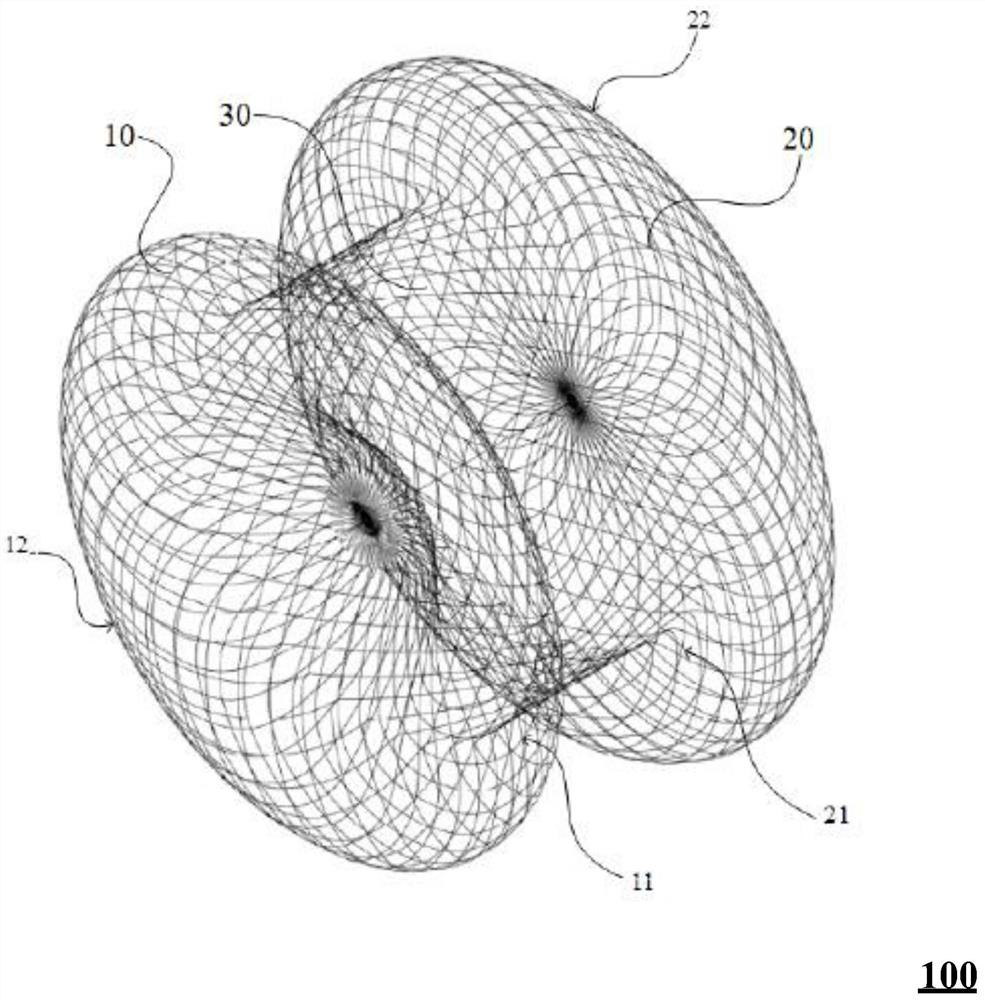

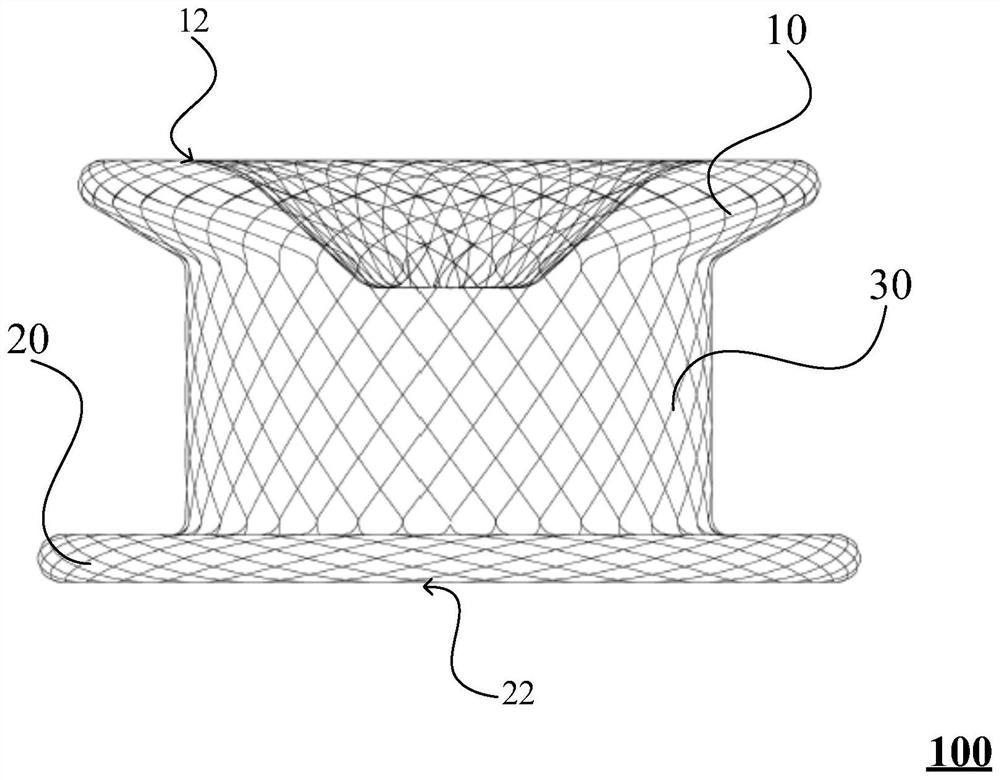

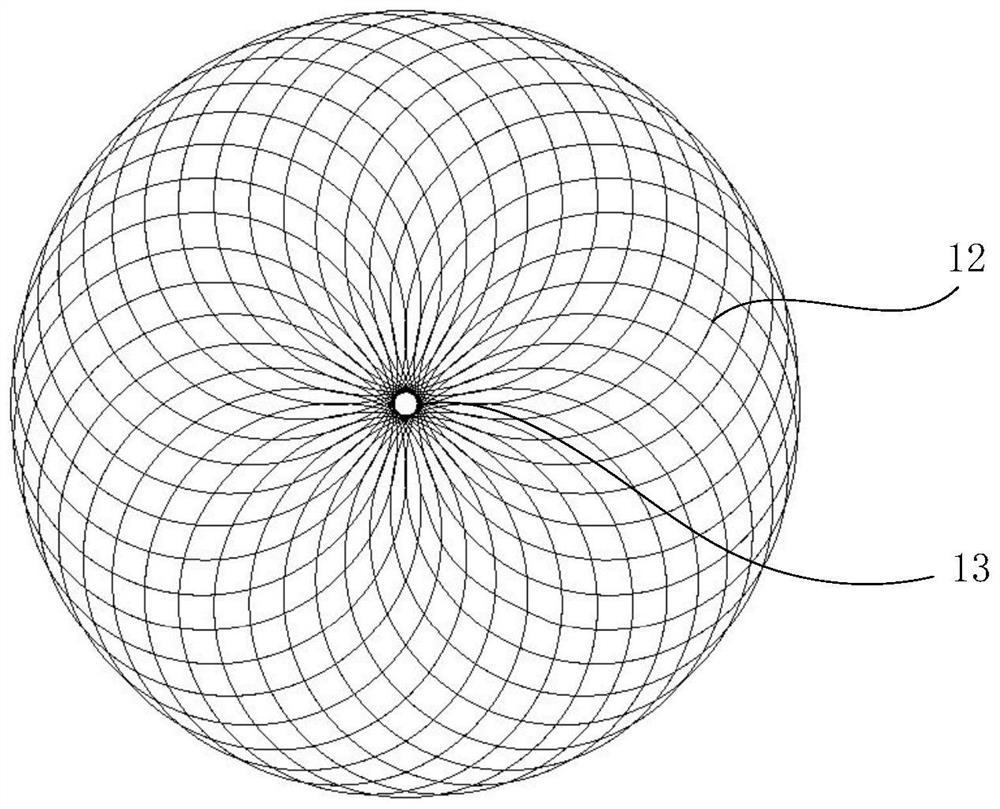

[0154] This embodiment discloses a heart ventricular septal defect occluder with flat ends, such as Figure 1-4 As shown, the cardiac ventricular septal defect occluder 100 includes a main body part, a flow blocking part (not shown) and a suture (not shown); wherein, the main part is woven from degradable silk or non-degradable silk, and the main part is a mesh Body structure and includes the first disc-shaped part 10, the tubular part 30 and the second disc-shaped part 20 connected in sequence, the first disc-shaped part 10 and the second disc-shaped part 20 are double-layer mesh surface, the two sides of the tubular part 30 The ends are respectively connected to the inner mesh surface 11 of the first disc-shaped part 10 and the inner mesh surface 21 of the second disc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com