Pneumatic conveying device and auxiliary pipeline control system of pneumatic conveying device

A technology of conveying pipelines and auxiliary pipelines, which is applied to conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of inaccurate adjustment of conveying air volume, low utilization rate of fluidizing nozzles and pressurizing nozzles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

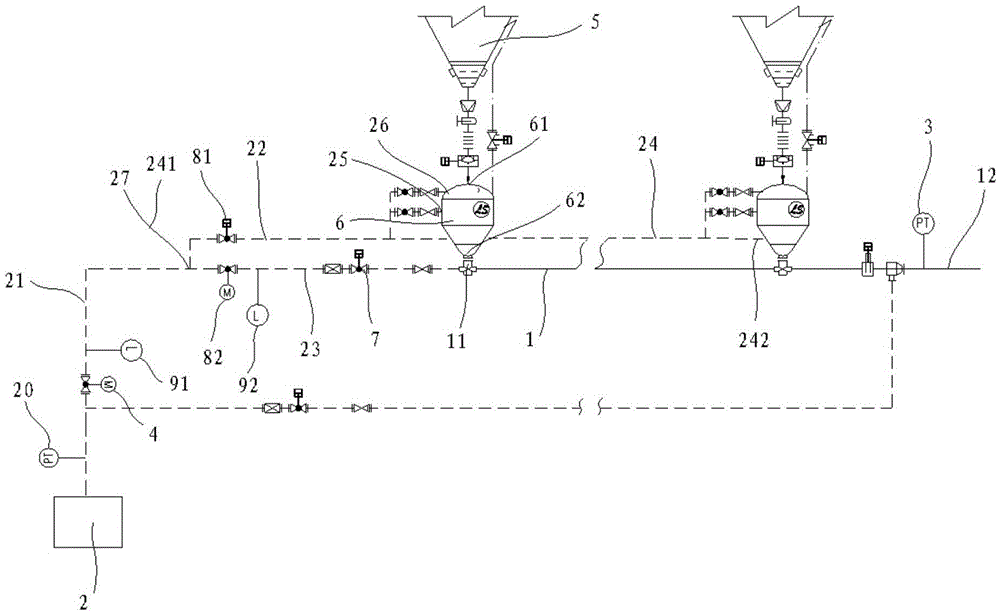

[0088] Such as figure 1 Shown, a kind of pneumatic conveying device of the present invention comprises:

[0089] A conveying pipeline 1, at least one material drop port 11 is provided on the side wall of the conveying pipeline 1;

[0090] The air intake device 2 communicates with the conveying pipeline 1, injects compressed air into the conveying pipeline 1, and transports the materials falling into the conveying pipeline 1;

[0091] Also includes:

[0092] The material path pressure detection device 3 is arranged between the material falling inlet 11 downstream of the conveying pipeline 1 close to the inlet device 2 and the discharge end 12 of the conveying pipeline 1, and detects that the conveying pipeline 1 The material path pressure;

[0093] The main flow adjustment device 4 is used to adjust the gas flow rate of the air intake device 2 to the delivery pipeline 1;

[0094] The intelligent control system is used to control the adjustment of the main flow regulating devi...

Embodiment 2

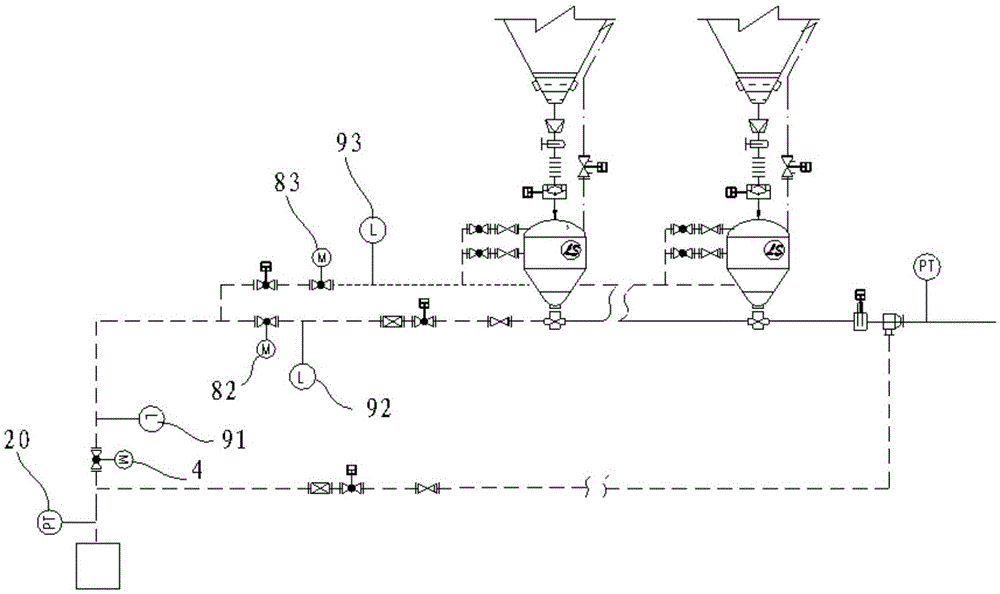

[0143] Such as figure 2 As shown, this embodiment is substantially the same as Embodiment 1, except that the specific form and arrangement of the flow regulating device and the flow detecting device are different.

[0144] In this embodiment, the flow regulating device includes an auxiliary pipeline flow regulating device 83, which is arranged on the auxiliary pipeline 24 and is located between the branch 27 and the first delivery tank 6 close to the branch 27. time, used to adjust the real-time gas flow of the auxiliary pipeline 24;

[0145] The flow detection device includes an auxiliary pipeline flow detection device 93, which is arranged on the auxiliary pipeline 24 and between the auxiliary pipeline flow adjustment device 83 and the first delivery tank 6 near the branch 27 , detecting the real-time gas flow rate of the auxiliary pipeline 24 and feeding it back to the controller.

[0146] As a modified embodiment, the flow regulating device further includes a conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com