Automatic feeding multi-head melt extrusion forming 3d printing equipment

A melt extrusion, 3D printing technology, applied in metal processing equipment, 3D object support structures, manufacturing tools, etc., can solve problems such as low work efficiency and slow printing speed, save production costs, increase stability, reduce effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

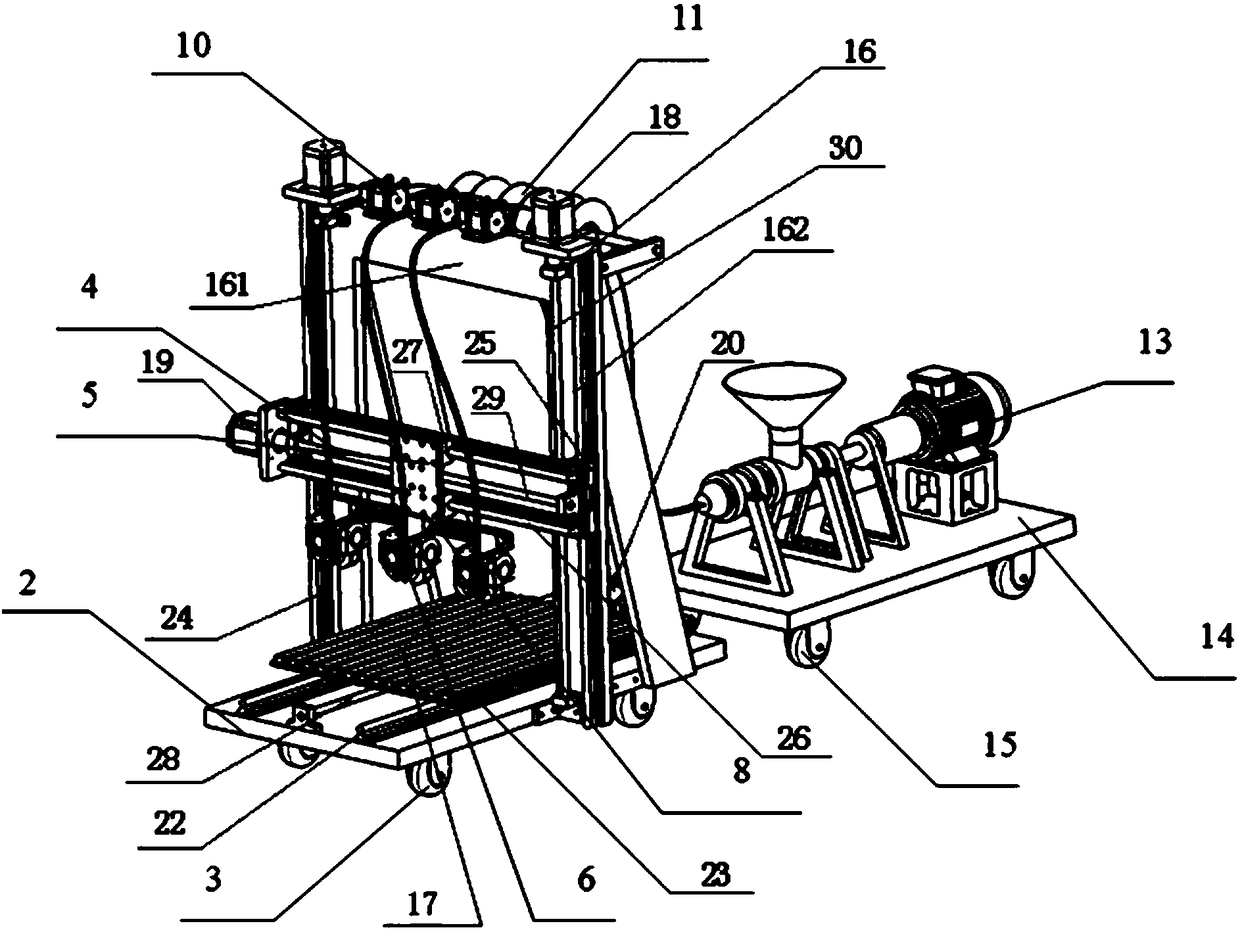

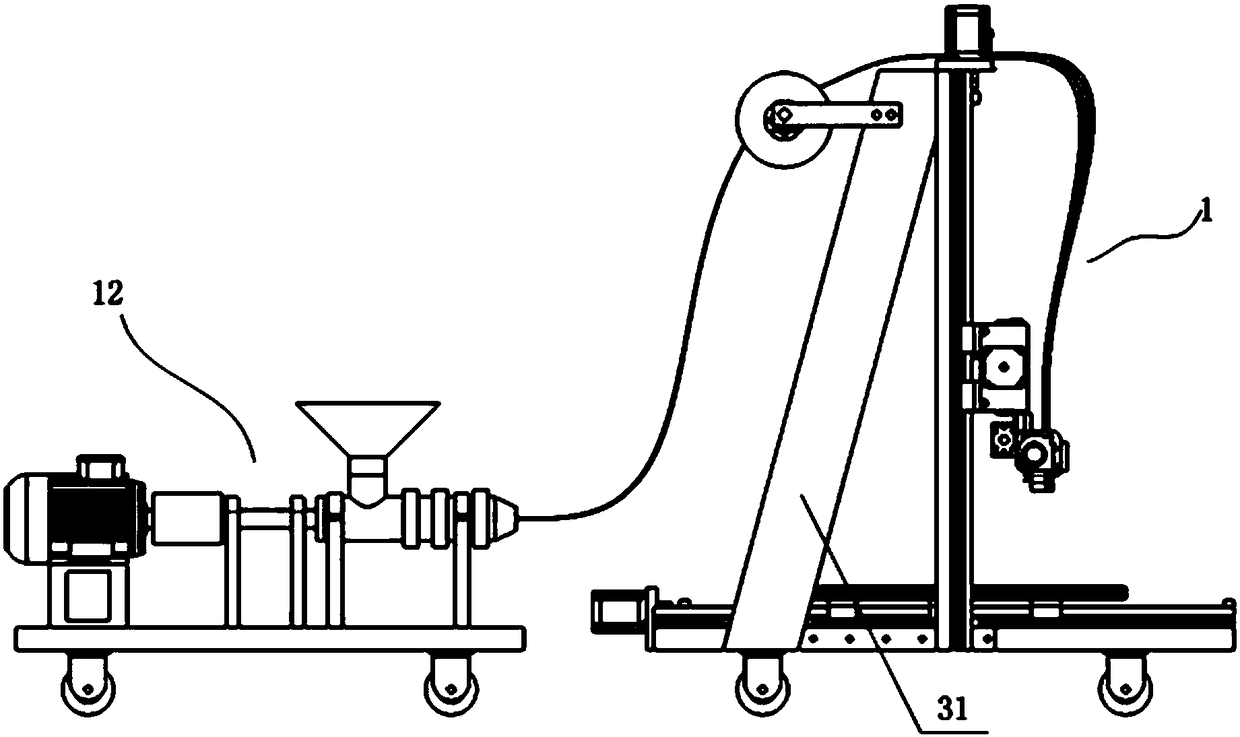

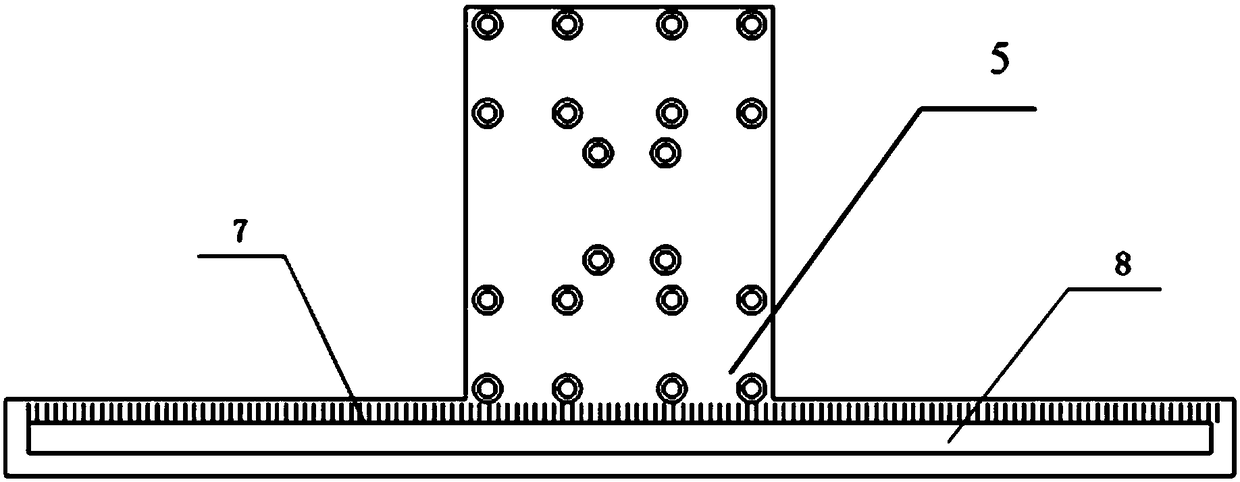

[0029] Such as Figure 1 to Figure 4 The automatic feeding multi-head melt-extrusion 3D printing equipment shown includes a 3D printer 1 and an injection molding machine 12; the 3D printer 1 includes a 3D printer base 2, a 3D printer bracket 16 fixed on both sides of the 3D printer base 2, The X-axis module 4 which is arranged on the 3D printer support 16 and forms a vertical movement pair with the 3D printer support 16, and the print head mounting plate 5 which is arranged on the X-axis module 4 and the X-axis module 4 constitutes a horizontal movement pair. The 3D printer base 2 and the 3D printer base 2 form a horizontally movable printing object support platform 17, the print head mounting plate 5 and the printing object support platform 17 move in a vertical direction, the print head mounting plate 5 is in an inverted T shape, and the print head The vertical part of the mounting plate 5 is slidably mounted on the X-axis module 4, and several print heads 6 are detachably mo...

Embodiment 2

[0040] Compared with the first embodiment, the difference between this embodiment and the first embodiment is that the number of the first motors 18 is two, which are respectively fixed on the top of the two vertical supports 162, and the output shafts of the two first motors 18 are each provided with a first motor. The screw 30 and the two first screw rods 30 are respectively screwed to the two ends of the X-axis module 4, and the rotation direction and pitch of the two first screw rods 30 are the same, and the two first motors 18 rotate synchronously. The rest of the structure is the same as the first embodiment.

Embodiment 3

[0042] The difference between this embodiment and the first embodiment is that the 3D printer 1 and the injection molding machine 12 have a separate structure. The bottom of the 3D printer base 2 is provided with a printer universal wheel 3, and the bottom of the injection molding machine 12 is provided with an injection molding machine universal wheel 15. The rest of the structure of this embodiment is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com