Two-way automatic centering fixture

An automatic centering and fixture technology, applied in the field of mechanical processing, can solve the problems of increasing processing costs and high processing costs, and achieve the effects of shortening the manufacturing cycle, low processing accuracy requirements, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

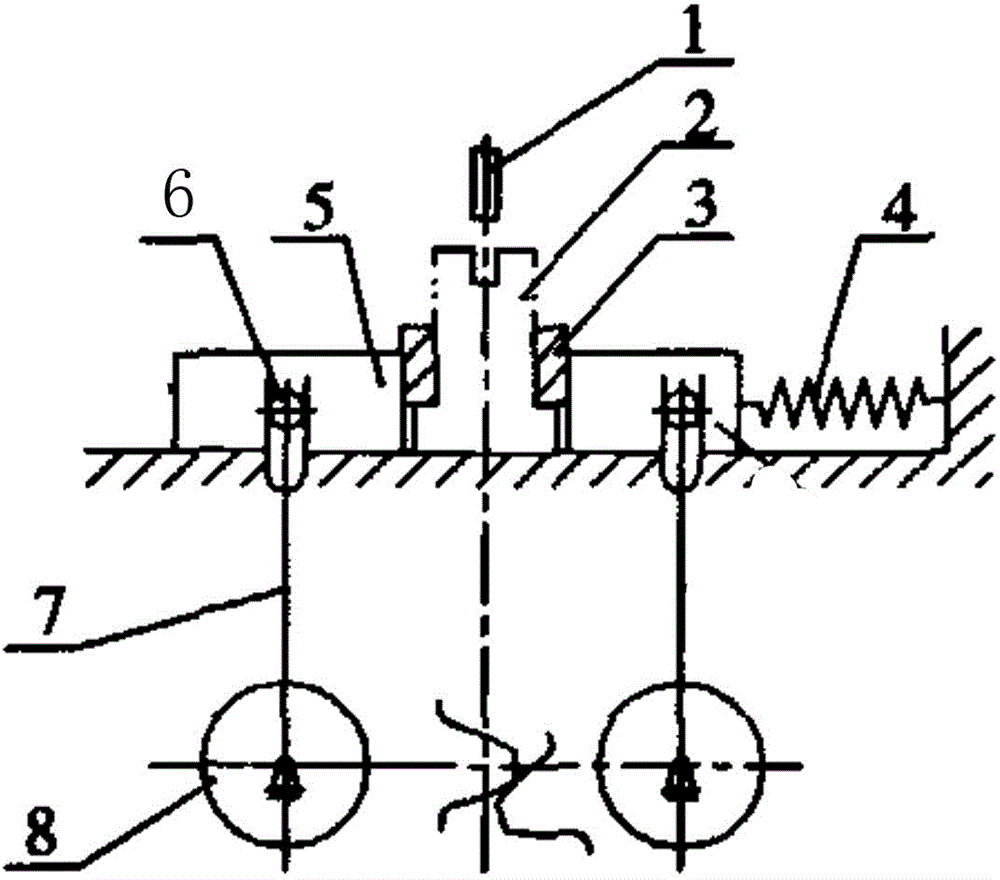

[0010] The two-way self-centering fixture of the present invention includes two clamping jaws 5 arranged on the workbench, one remote end of the two clamping jaws 5 is connected to the clamping wheel of the machine tool, and the other remote end is connected to the machine tool through a tension spring 4 The two clamping jaws 5 are respectively provided with two driving rods 7, one end of the two driving rods 7 is connected with the clamping jaws 5 through the pin shaft 6, and the other end is connected with the gear 8, The driving lever 7 can drive the gear 8 to rotate, and the two gears 8 are meshed with each other. Two shims 3 are arranged symmetrically on the clamping jaw 5 , and the positions of the shims 3 on the clamping jaw 5 are at the same height. The positions of the two driving levers 7 respectively located on the two clamping jaws 5 are symmetrical to each other.

[0011] During processing, the milling cutter 1 is located at the center of the two clamping jaws 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com