Compound protein powder easy to absorb and preparation method thereof

A technology of compounding protein and protein powder, applied in protein food processing, vegetable protein processing, protein food ingredients, etc., can solve the problems of high proportion of large molecular weight protein, unsatisfactory absorption effect, small molecular weight, etc., to enhance function and increase lymphatic The total number of cells, the effect of improving endurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

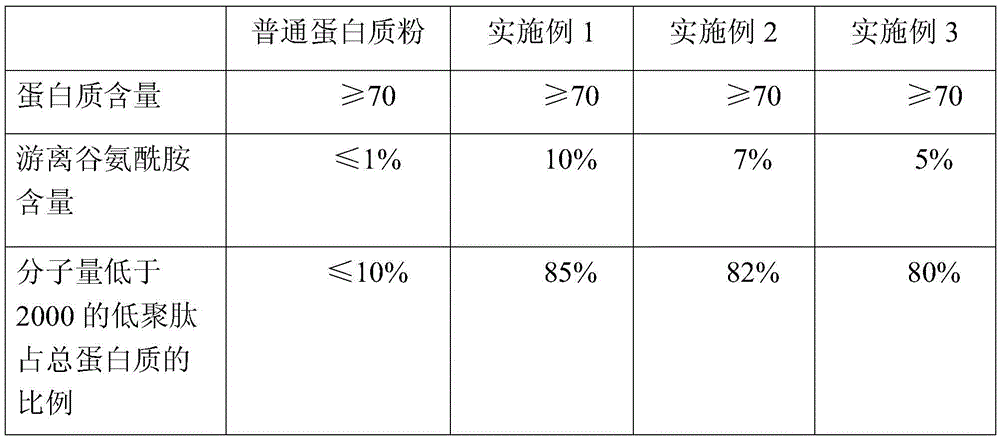

Examples

Embodiment 1

[0023] Weigh 3kg of soybean protein powder, 9kg of yeast protein powder and 3kg of glutinous rice flour and mix evenly, use 85L of water to set the volume to 15% concentration (w / v), stir for 30 minutes to make it mix evenly to obtain a raw material solution. Then add 0.2 kg of papain, adjust the pH of the solution to 5.5-5.8, and carry out enzymatic hydrolysis for 18 hours at a temperature of 55°C. Stir for 15 minutes every hour during enzymatic hydrolysis. After the enzymatic hydrolysis, use a 200-mesh sieve to filter out the insoluble components, concentrate under reduced pressure to a mass concentration of 30%, and spray dry to obtain the final product.

Embodiment 2

[0025] Weigh 3kg of soybean protein powder, 4kg of yeast protein powder and 3kg of glutinous rice flour and mix them uniformly, dilute to 10% concentration (w / v) with 90L of water, stir for 30 minutes to make it mix uniformly to obtain a raw material solution. Then add 0.5 kg of alkaline protease, adjust the pH of the solution to 6.5-6.8, and carry out enzymatic hydrolysis for 8 hours at a temperature of 57°C. Stir for 15 minutes every hour during enzymatic hydrolysis. After the enzymatic hydrolysis, use a 200-mesh sieve to filter out the insoluble components, concentrate under reduced pressure to a mass concentration of 20%, and spray dry to obtain the final product.

Embodiment 3

[0027] Weigh 6kg of soybean protein powder, 1kg of yeast protein powder and 3kg of glutinous rice flour and mix them uniformly, dilute to 10% concentration (w / v) with 90L of water, stir for 30 minutes to make it mix uniformly to obtain a raw material solution. Then add 0.3 kg of papain, adjust the pH of the solution to 5.5-5.8, and carry out enzymatic hydrolysis for 10 hours at a temperature of 56°C. Stir for 15 minutes every hour during enzymatic hydrolysis. After the enzymatic hydrolysis, use a 200-mesh sieve to filter out the insoluble components, concentrate under reduced pressure to a mass concentration of 25%, and spray dry to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com