Method for continuous laser processing using multi-position control, and system employing same

A laser processing method and laser processing technology, applied in the direction of manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve problems such as reduced productivity and poor processing, and achieve the effects of high productivity, excellent processing quality, and fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, preferred embodiments of the laser processing method according to the present invention will be described in detail with reference to the accompanying drawings.

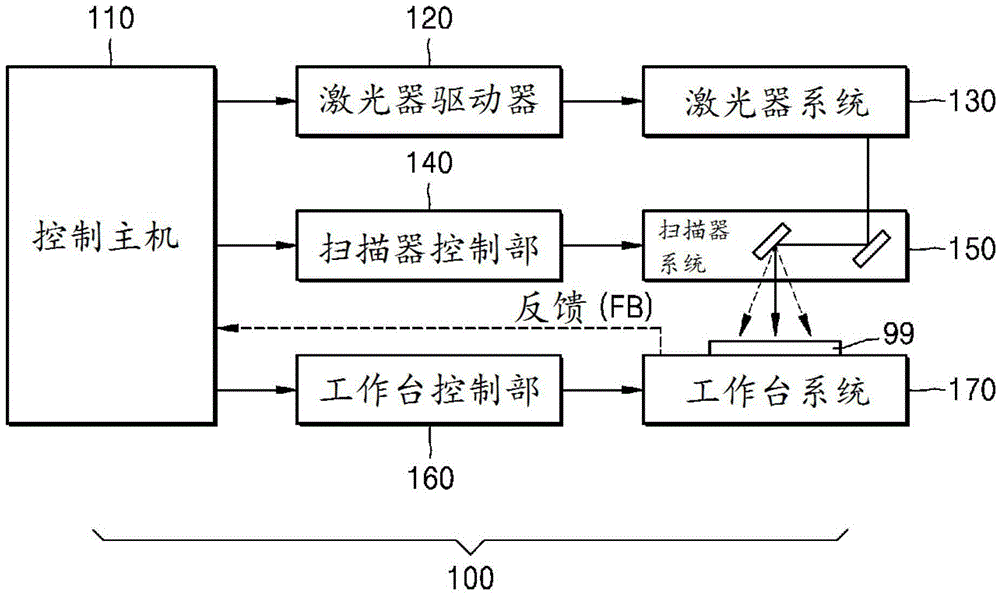

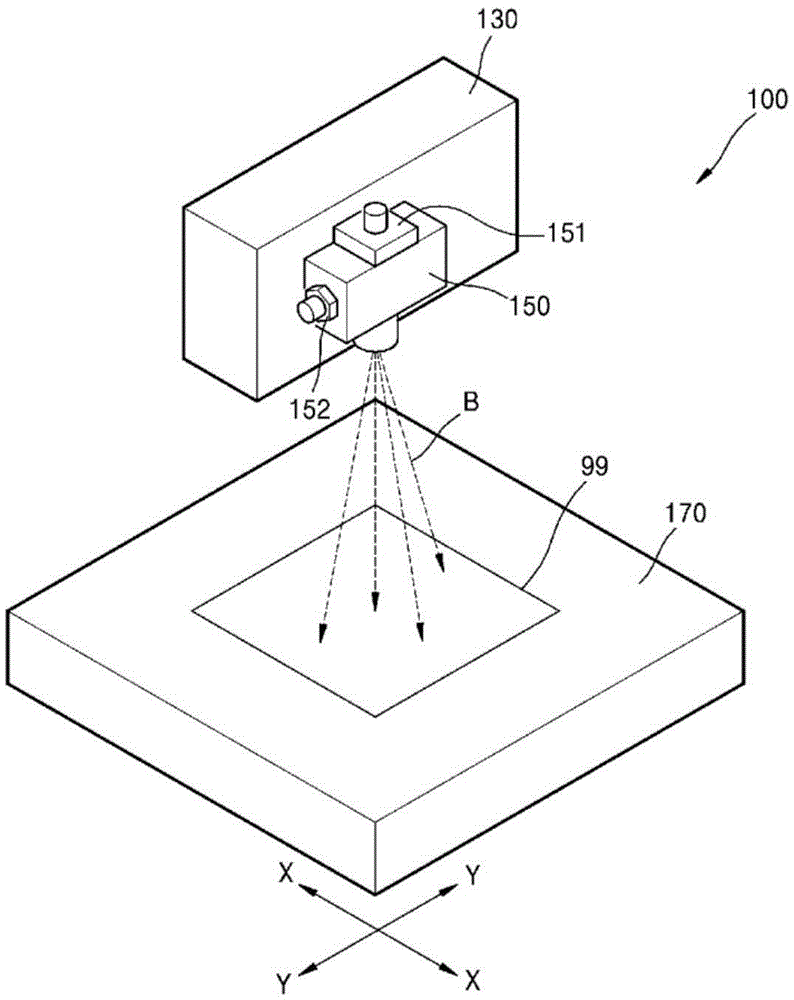

[0046] refer to figure 1 , laser processing system (LaserMachiningSystem) 100 is also called laser marking machine (marker) usually, comprises: workbench system (hereinafter referred to as workbench) 170, load workpiece 99 in described workbench system; Laser system (LaserSystem) 130, the laser system 130 generates a laser beam (LaserBeam) B in a high-energy state required for machining the workpiece 99; and a scanner system (hereinafter referred to as a scanner) 150, the scanner system 150 has A plurality of galvanometers (151, 152) that focus or localize the laser beam from the laser system 130 to specific locations on the workpiece. The worktable 170 is used as a low-speed driver to move on the X-Y coordinates in the direction parallel to the plane of the workpiece 99. The scanner system 150 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com