Excess stock management method and apparatus

A technology of residual material and cutting device, applied in data processing applications, instruments, logistics, etc., can solve the problems of low utilization rate of residual material, lack of methods for residual material management, etc., and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

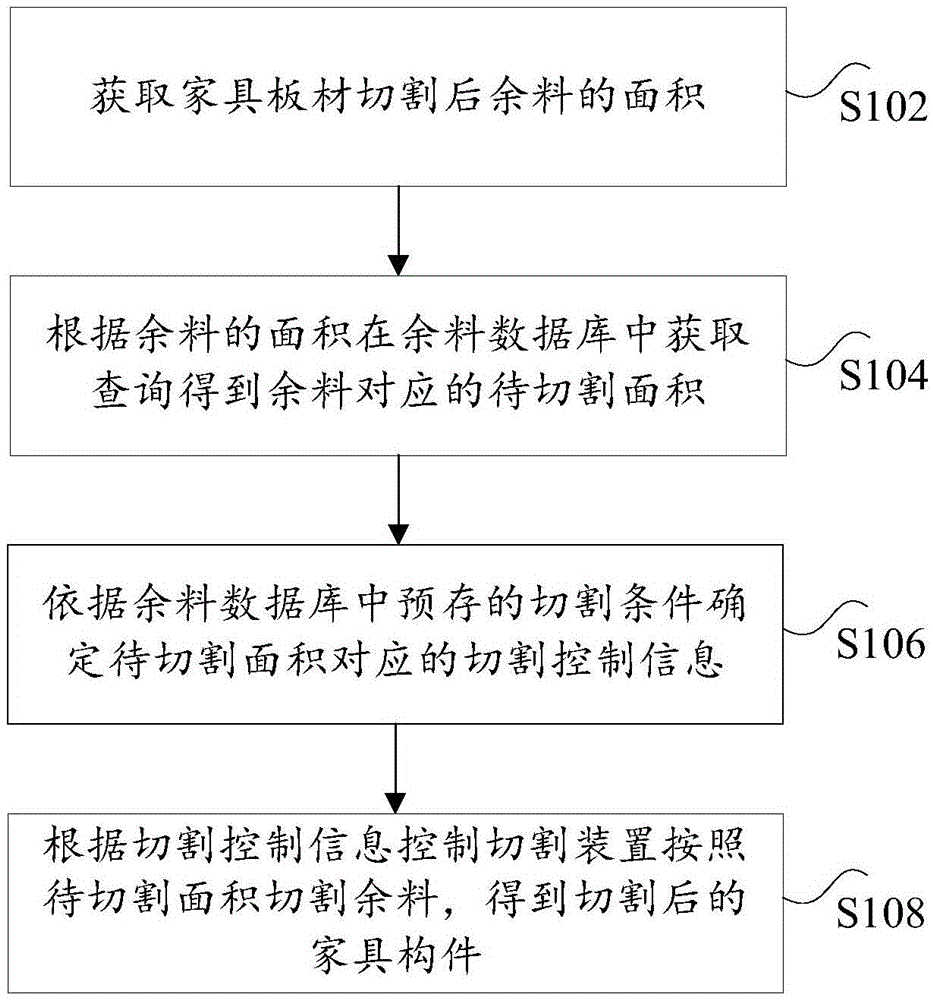

[0026] According to an embodiment of the present invention, a method embodiment of a method for residual material management is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions, Also, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0027] figure 1 It is a schematic flow chart of a method for residual material management according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0028] Step S102, obtaining the area of the remaining material after cutting the furniture board.

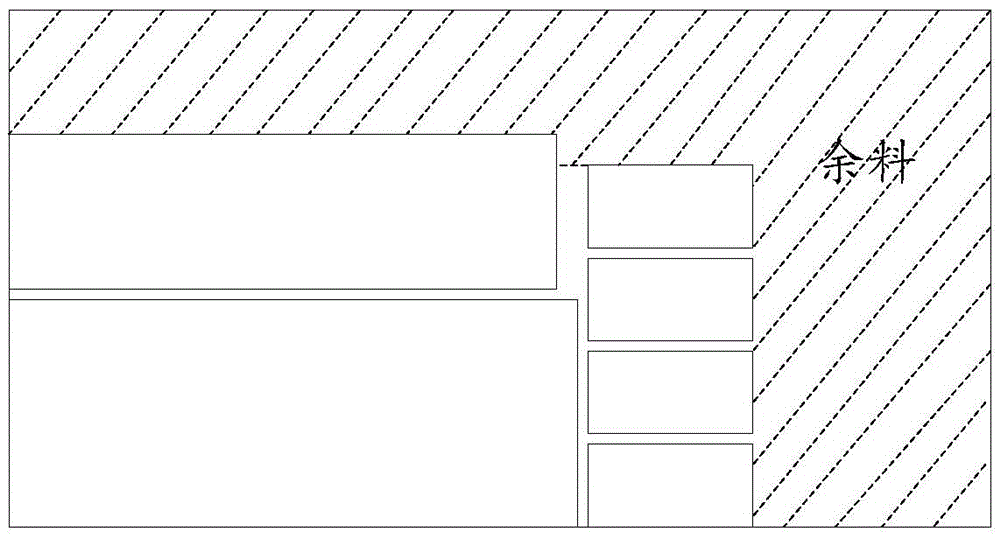

[0029] Specifically, the residual material management method provided in the embodiment of the present application can be used to manage and utilize the residual material (ie, resid...

Embodiment 2

[0068] According to an embodiment of the present invention, a device embodiment of a residual material management device is provided, Figure 7 It is a schematic structural diagram of a device for residual material management according to an embodiment of the present invention, such as Figure 7 As shown, the device includes: an acquisition module 72, a query module 74, an information determination module 76 and a cutting module 78, wherein,

[0069] An acquisition module 72, configured to acquire the area of the remaining material after the furniture plate is cut;

[0070] Inquiry module 74, is used for inquiring in the remaining material database according to the area of the remaining material to obtain the area to be cut corresponding to the remaining material;

[0071] An information determination module 76, configured to determine the cutting control information corresponding to the area to be cut according to the cutting conditions prestored in the remaining materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com