Vibration scratch detection method

A detection method and wheel abrasion technology, applied in the field of detection, can solve problems such as easy misjudgment, unavoidable influence, breakage, etc., and achieve the effect of protecting life and property, ensuring driving safety, and ensuring driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

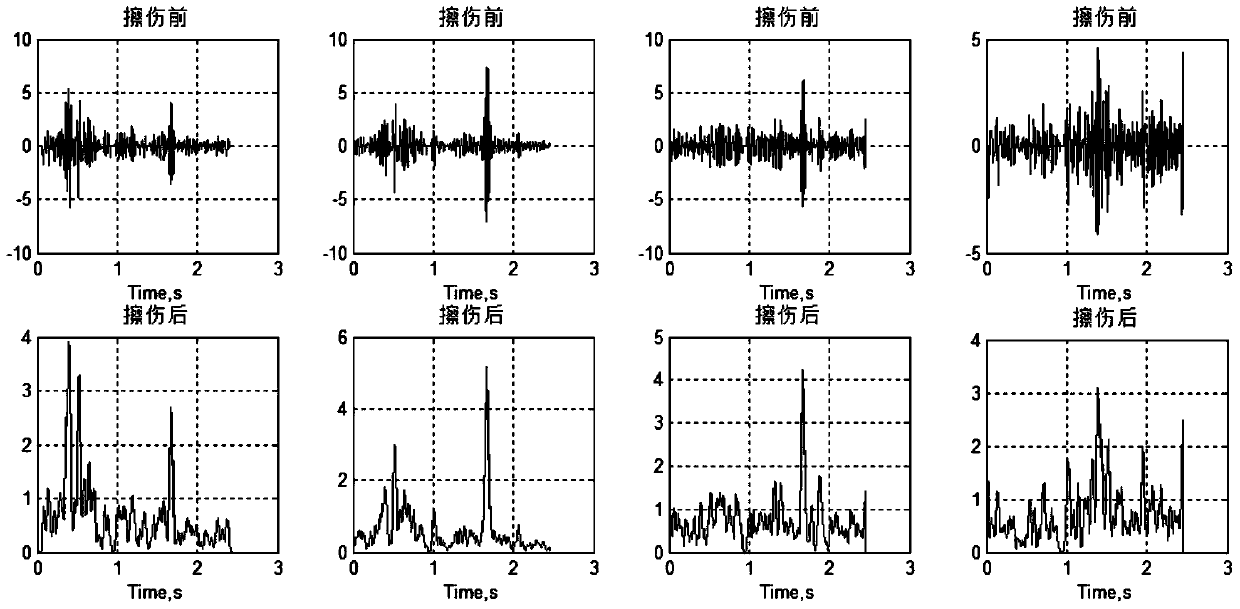

[0027] A method for detecting vibration scratches, identifying wheel scratches by detecting the up and down vibration amplitude of a track during vehicle operation, comprising the following steps:

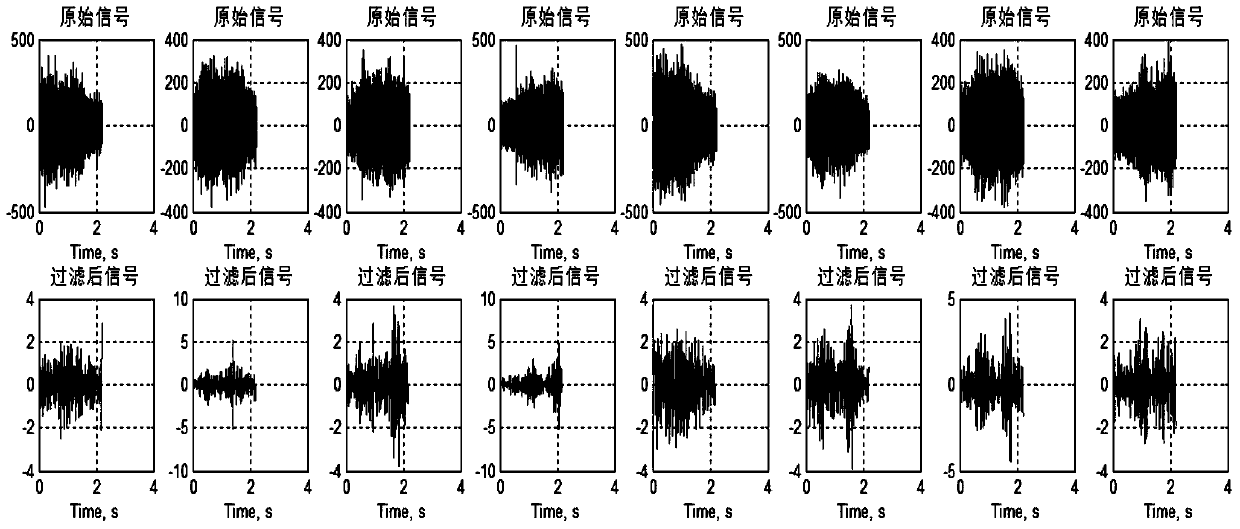

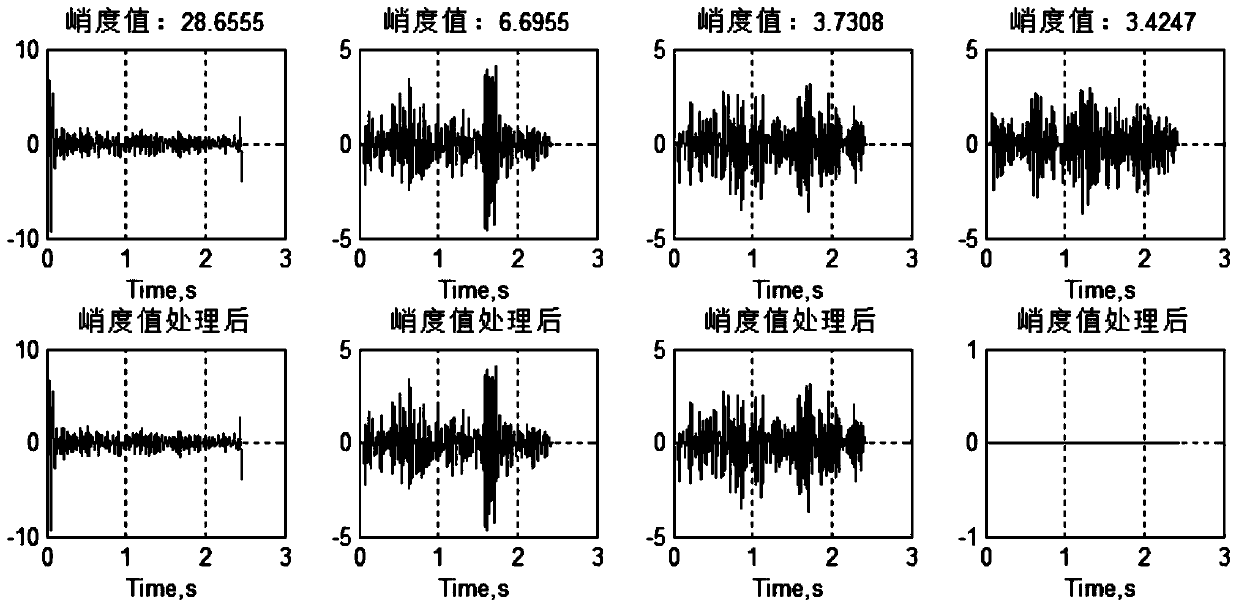

[0028] Step (1): Detect impact signal, provide several sensors, these several sensors are distributed on the same side of track, in the present embodiment, the quantity of described sensor is eight; The abrasion on the train wheel can cause the wheel to run on the track. There is a bumpy motion, and this motion will be transmitted to the track, and the sensor will detect this bumpy motion and convert the vibration amplitude of the track into an electrical signal, and the sensors will respectively extract eight groups of different electrical signals.

[0029] Step (2): filter processing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com